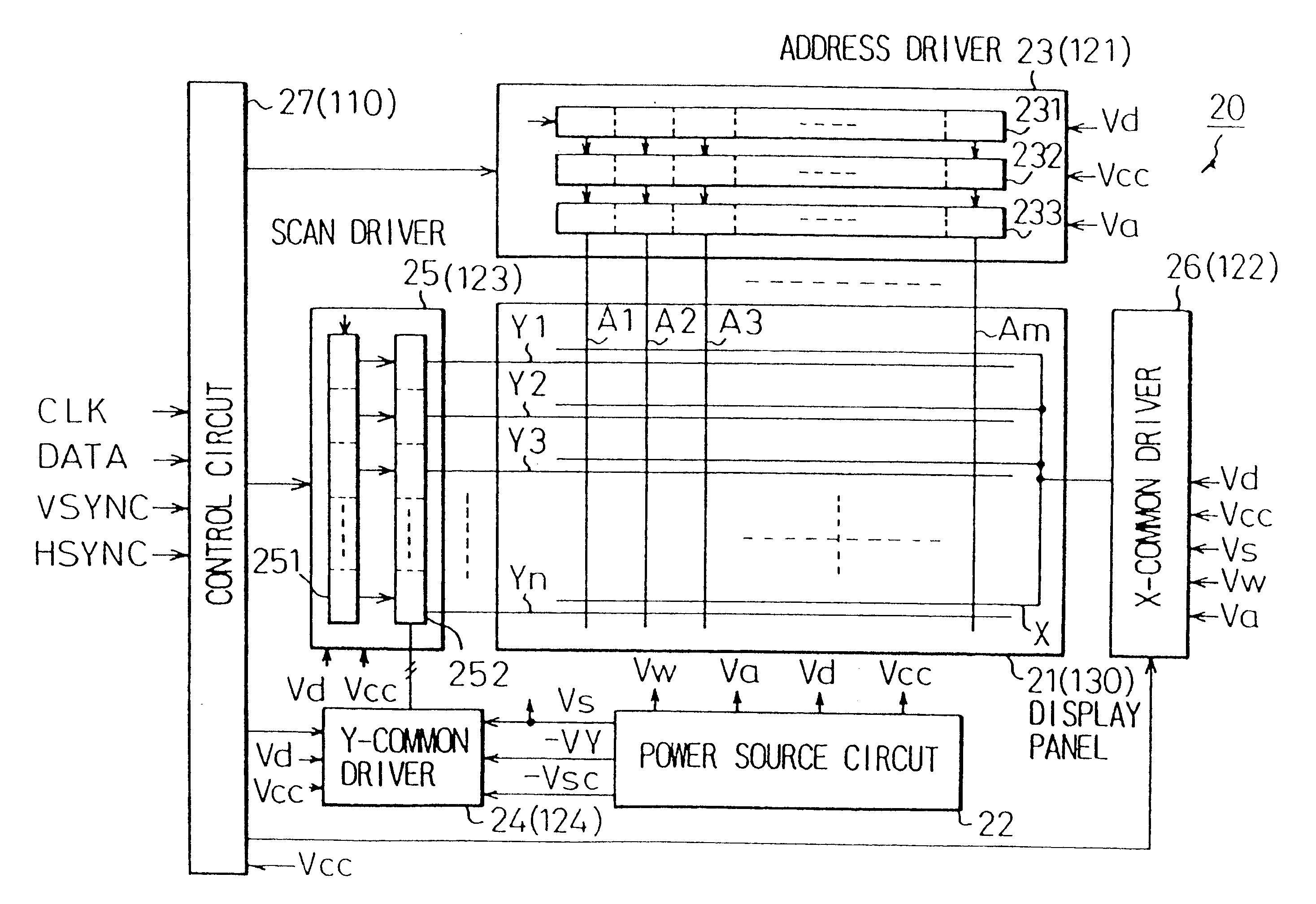

Method and apparatus for driving surface discharge plasma display panel

a plasma display and surface discharge technology, applied in the direction of gas-filled discharge tubes, electric discharge tubes, instruments, etc., can solve the problems of deteriorating pdp contrast, destabilizing the operation of pdp or lowering display quality, etc., to prevent an unnecessary current flow

- Summary

- Abstract

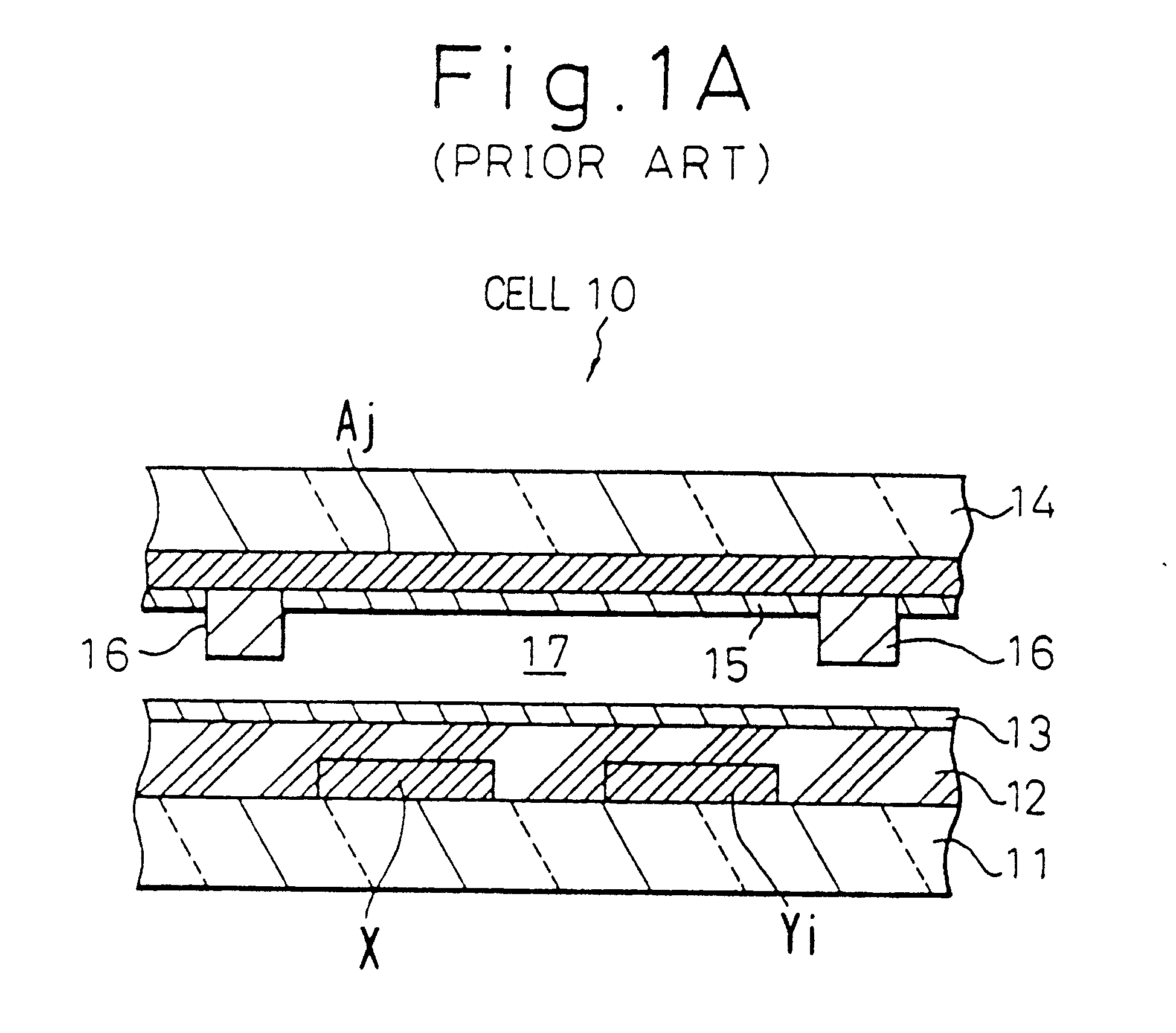

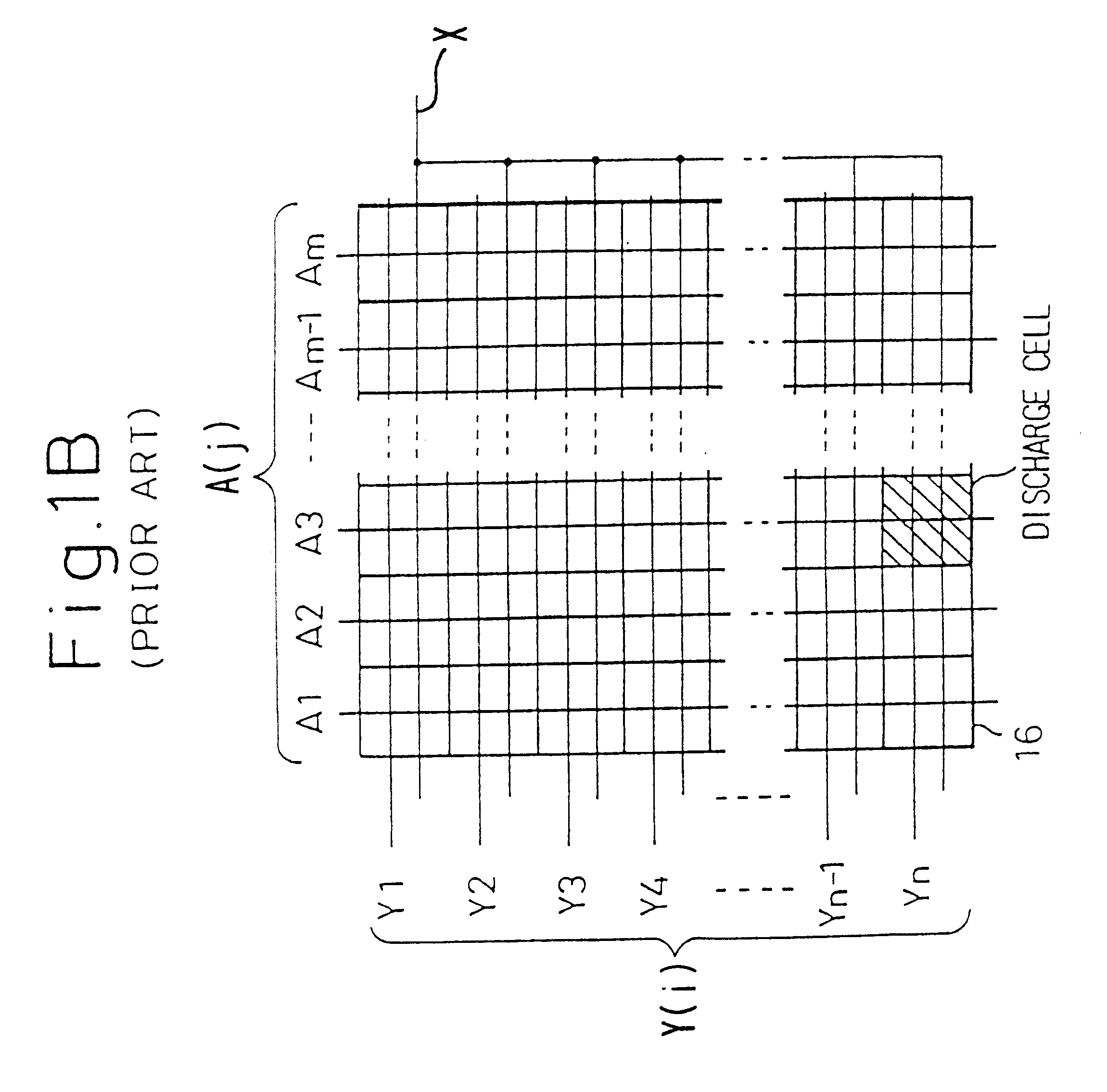

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

As described above, the present invention carries out the write discharge in all cells in the selected line and then carries out the self-erase discharge to nearly completely neutralize the wall charges. Accordingly, the conditions of all cells in the selected line are equalized before display data are written in the selected line. This results in expanding the range of the potential Va, always carrying out stable address discharge with no regard to the distribution of charges before the write discharge or changes in temperature, preventing write errors, and improving the display quality of the PDP.

Further, unlike the prior art of FIG. 2, no discharge occurs between the sustain electrodes X and Ys in the cells to be turned OFF in the process (1-c), so that the number of light emitting discharge operations carried out in all cells in the selected line is two in the write cycle, which is 2 / 3 of the operations used in the prior art. Accordingly, the ratio of the maximum luminance and t...

second embodiment

As described above, the second embodiment carries out the total write discharge and then the self-erase discharge to nearly completely neutralize wall charges. Accordingly, the conditions of all cells in a selected line are equalized before display data are written in the selected line during the address period. This results in expanding the range of the potential Va, always carrying out stable address discharge with no regard to the distribution of charges before write discharge or changes in temperature, preventing write errors, and improving the display quality of the PDP. Further, the number of discharge emissions in the reset period in each sub-field is two, which is 2 / 3 of the emission in the prior art. Namely, the ratio of the maximum luminance to the minimum luminance for displaying black is increased by 3 / 2 of the prior art, to thereby improve the quality of displaying shades of gray.

third embodiment

FIG. 10 shows a sub-field of voltage waveforms applied to the electrodes according to a PDP driving method based on the present invention. In FIG. 10, (i), (ii), (iii), (iv) and (v) are waveforms of address electrodes Aj, sustain electrodes X, sustain electrode Y1, sustain electrode Y2 and sustain electrode Yn, respectively.

By the way, a scan driver and an X-common driver (X driver) for carrying out sustain discharge and total write discharge consume larger power than other drivers, and are, therefore, large. On the other hand, a positive pulse generator is simpler and cheeper than the negative pulse generator. Therefore, the third embodiment of the present invention employs only positive pulses during the reset and sustain discharge periods.

(3-a) First, in the reset period, all electrodes are set to 0V, and a write pulse 222 of Vs+Vw is applied to the sustain electrodes X. At the same time, a pulse of Vaw is applied to the address electrodes A1 through Am. The reason why the potent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com