Precision direct drive mechanism for a power assist apparatus for a bicycle

a direct drive, bicycle technology, applied in the direction of vehicle components, rider propulsion, vehicle transmission, etc., can solve the problems of excessive wear and noise, difficult reengagement of direct drive power assist devices for bicycles, and general requirements for complex gearing arrangements, etc., to achieve fast conversion, maintain precision alignment, and reduce weight penalty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

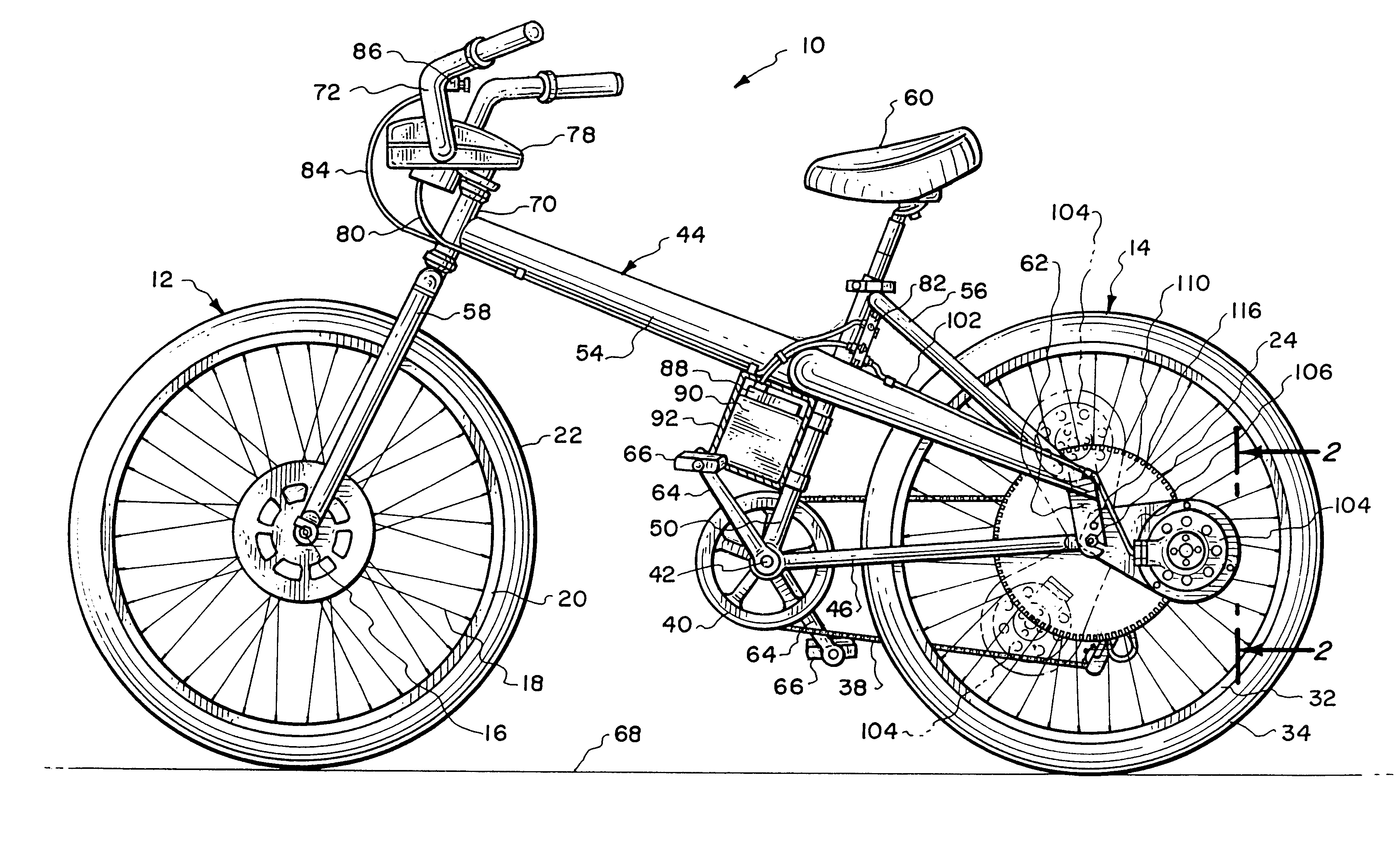

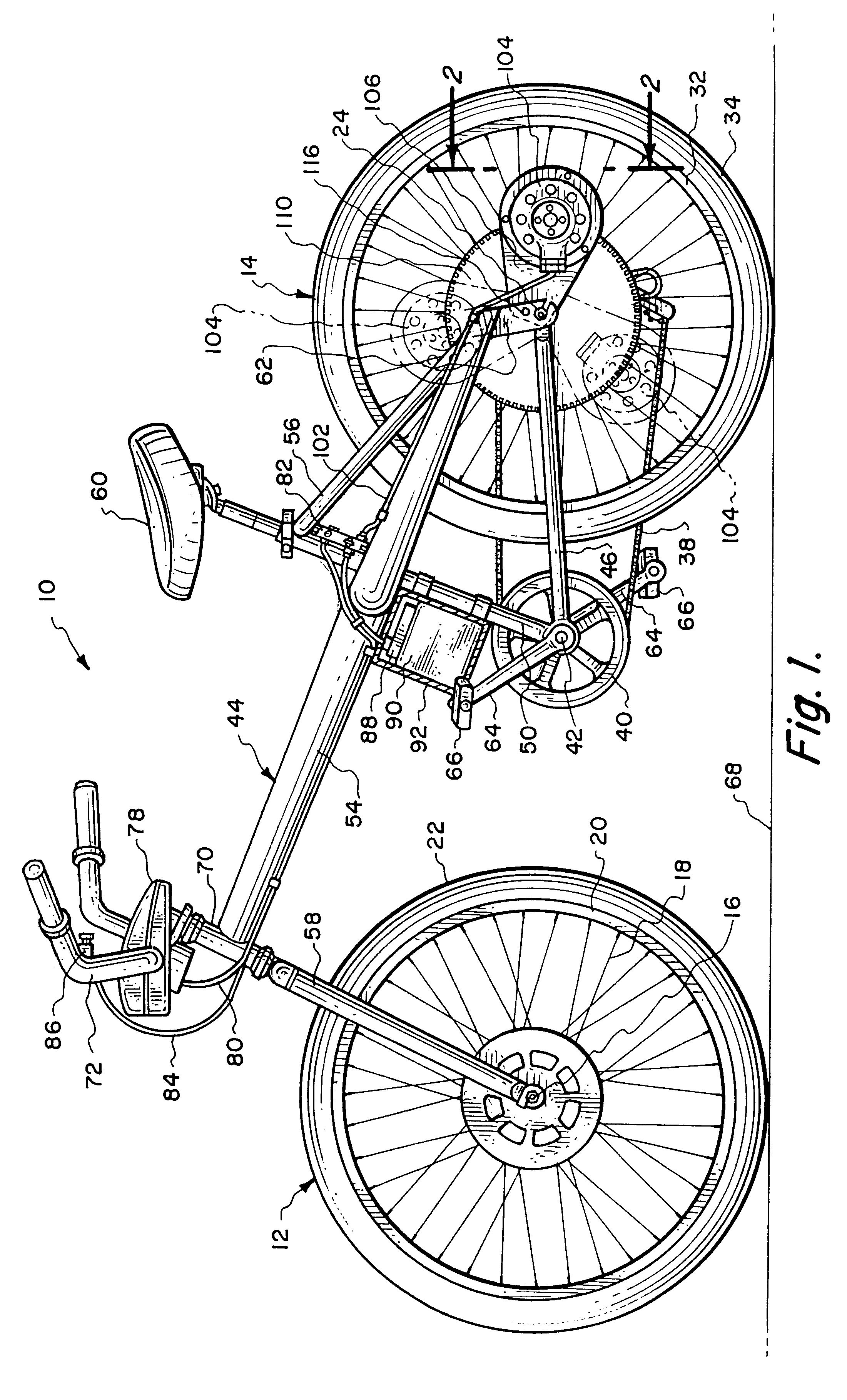

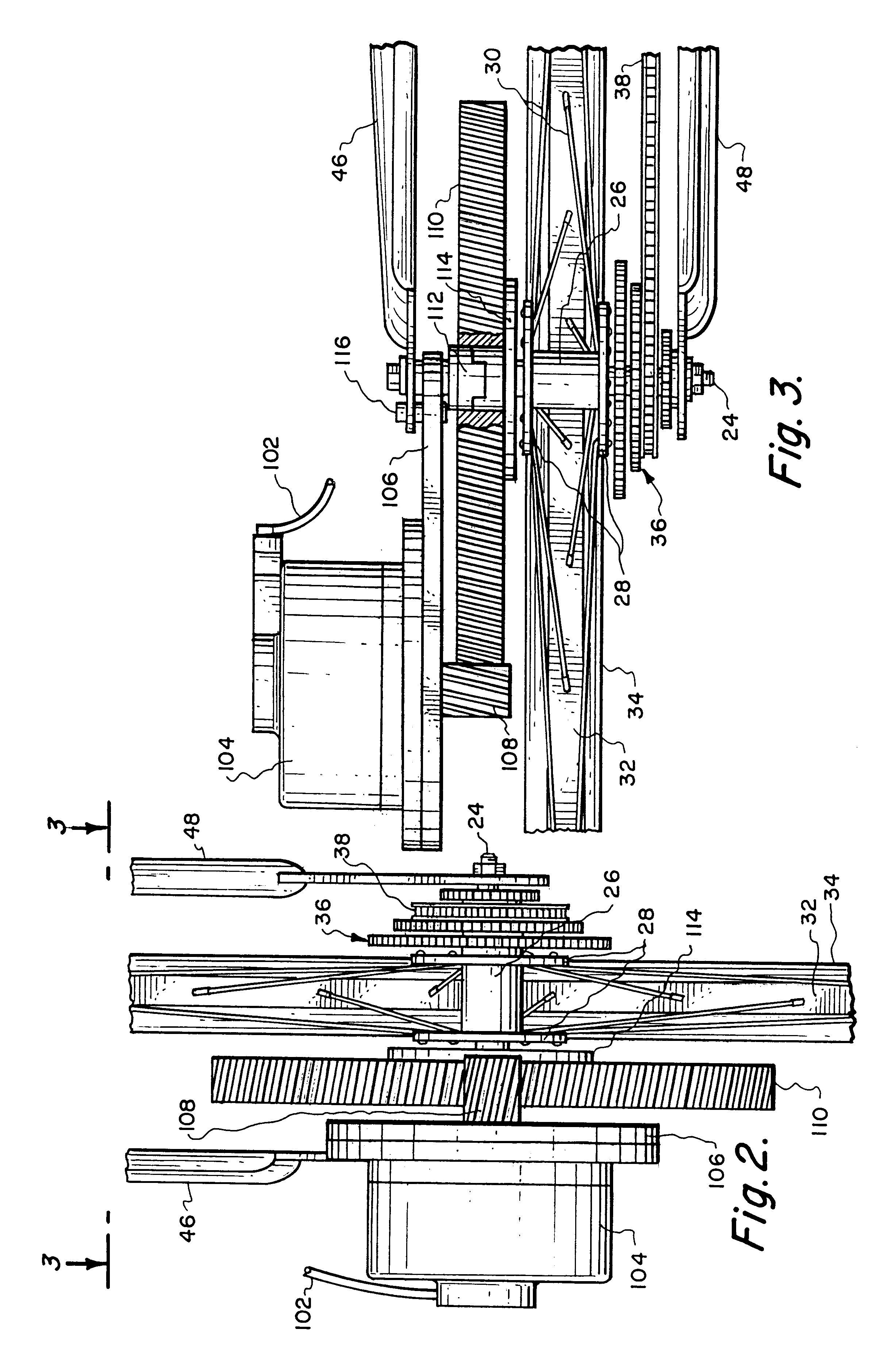

This invention is described in relation to a bicycle. However, it is understood that this invention could be used not only on a bicycle type vehicle that has two support wheels but also a bicycle type vehicle that has three or four support wheels. The word bicycle will be understood to include all such vehicles. The power assist apparatus could utilize an exterior gear connection, which is shown in the drawings, or could utilize an internal gearing arrangement mounted within the hub of the support wheel on which the motor of the power assist apparatus is mounted. Also, instead of gears, a chain or belt drive could be used.

Referring particularly to the drawings, there is shown a bicycle 10 having a front wheel 12 and a rear wheel 14. The rear wheel 14 is rotatable solely within a plane of rotation. The front wheel 12 includes an axle 16 from which extends a plurality of wire spokes 18. The wire spokes 18 are affixed to a tire rim 20 on which is mounted a rubber tire 22. In a similar ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com