High-density cable distribution frame

a high-density, fiber-optic cable technology, applied in the field of high-density fiber-optic cable distribution frames, can solve the problems of unsatisfactory or excessive fiber-optic cable displacement, bending and other forces, and prior art products that require substantial fiber-optic cable displacemen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

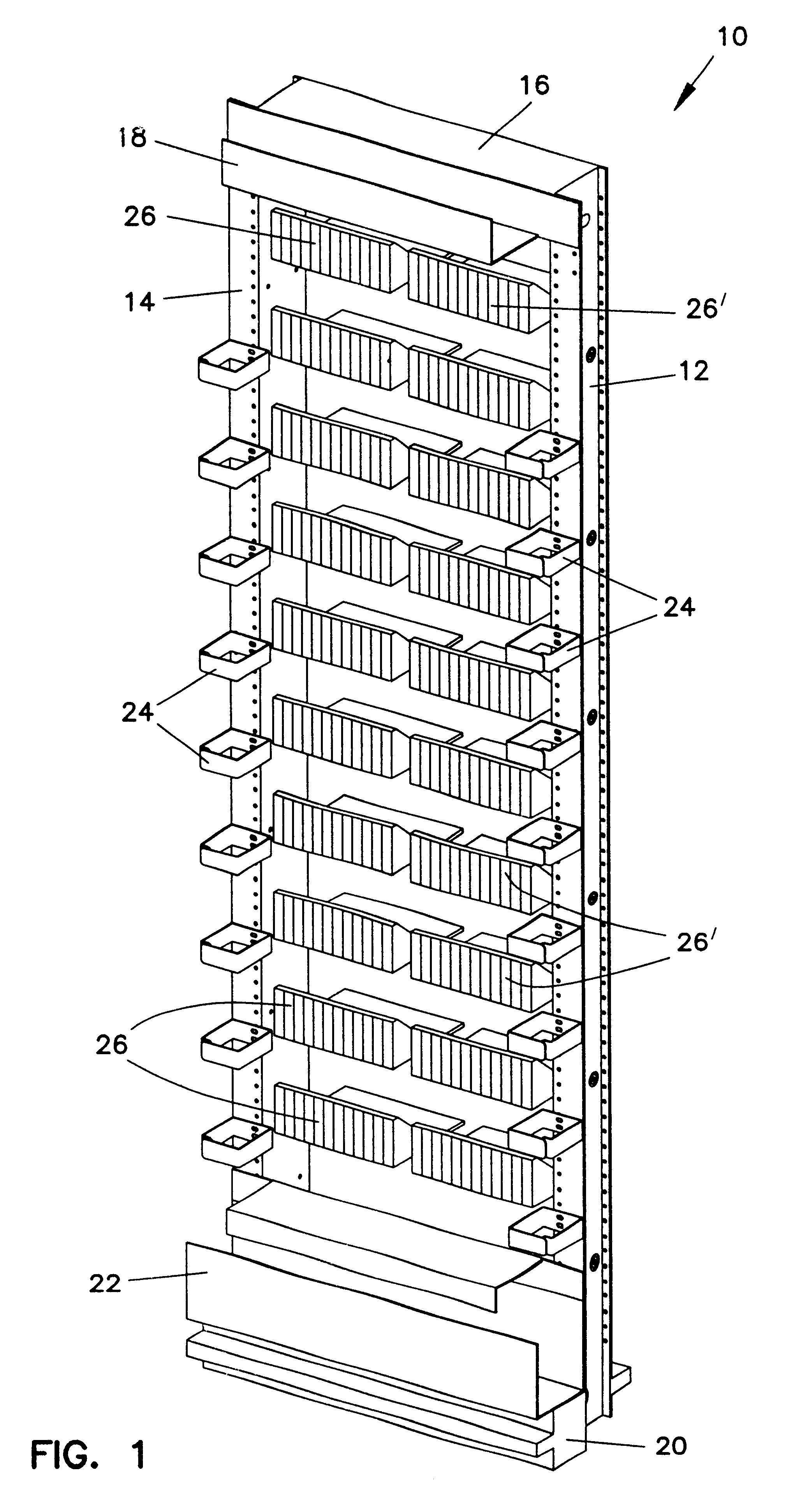

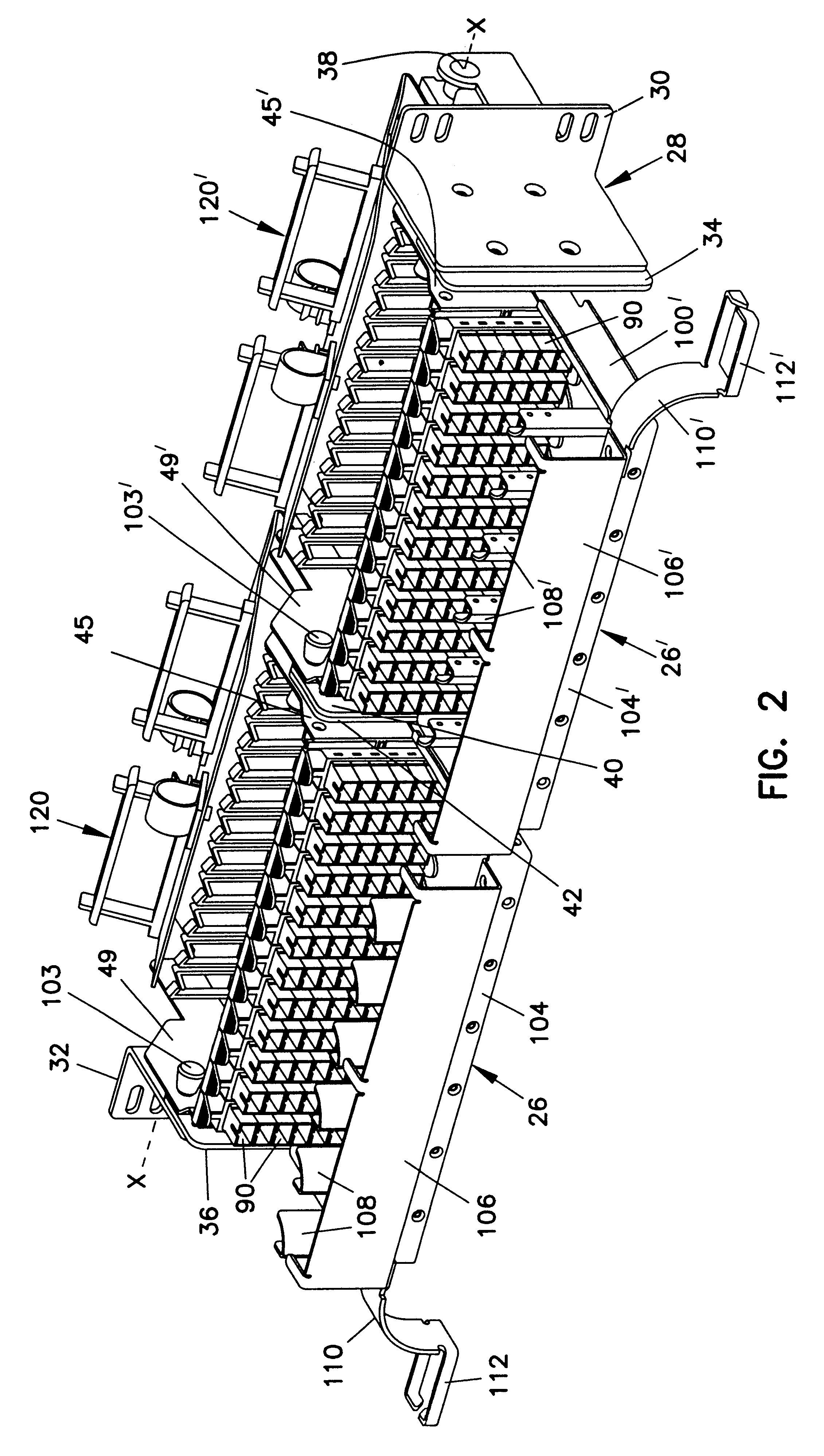

With reference now to the several drawing figures in which identical elements are numbered identically through-out, a description of the preferred embodiment of the invention will now be provided.

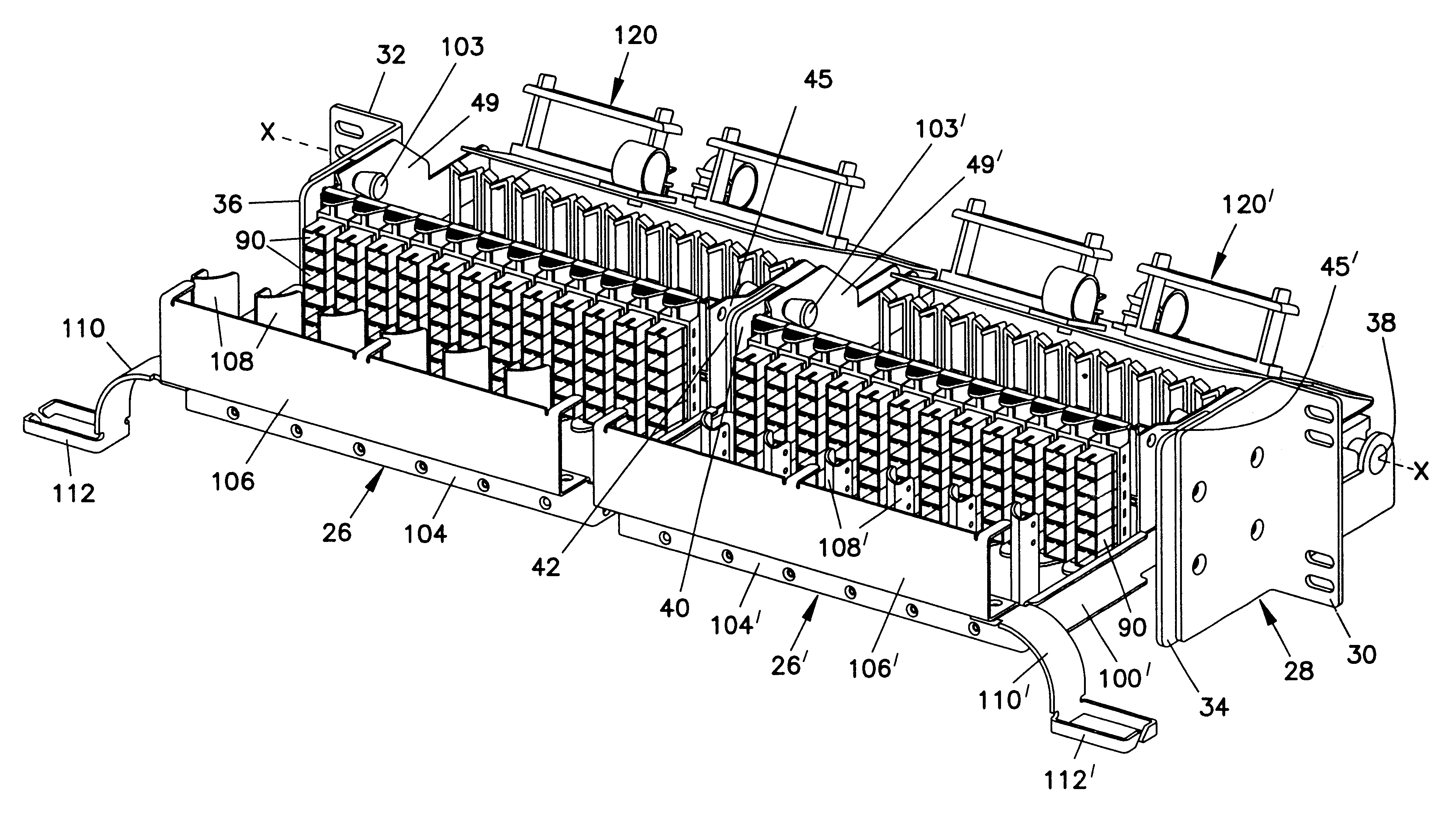

With initial reference to FIG. 1, a fiber distribution frame 10 is shown. The frame 10 includes spaced-apart side walls 12,14 connected at their upper ends by a top wall 16. Connected to the forward side of the top wall 16 is a trough 18 for carrying cables and the like as is conventional. The bottom of the frame 10 is provided with a pedestal 20 which also has secured to it a trough 22 for carrying cables and the like. The forward edges of the side walls 12,14 are provided with a plurality of clips 24 for holding fiber optic cables extending vertically in front of side walls 12,14.

Contained within frame 10 between side walls 12,14 are a plurality of left and right mounting fixtures 26,26' (schematically shown in FIG. 1). A detailed description of mounting fixtures 26,26' is provided elsewh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com