Multiple effect pyrotechnic shell

a pyrotechnic shell and multi-effect technology, applied in the field of pyrotechnic devices, can solve the problems of tertiary and higher-level breaks that cannot be controlled, break shells that fail to include features which permit tertiary and higher-level breaks, and the limitations of combining more than one effect or breaking into a single artillery shell, etc., to achieve the effect of inhibiting the occurrence of ground explosions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

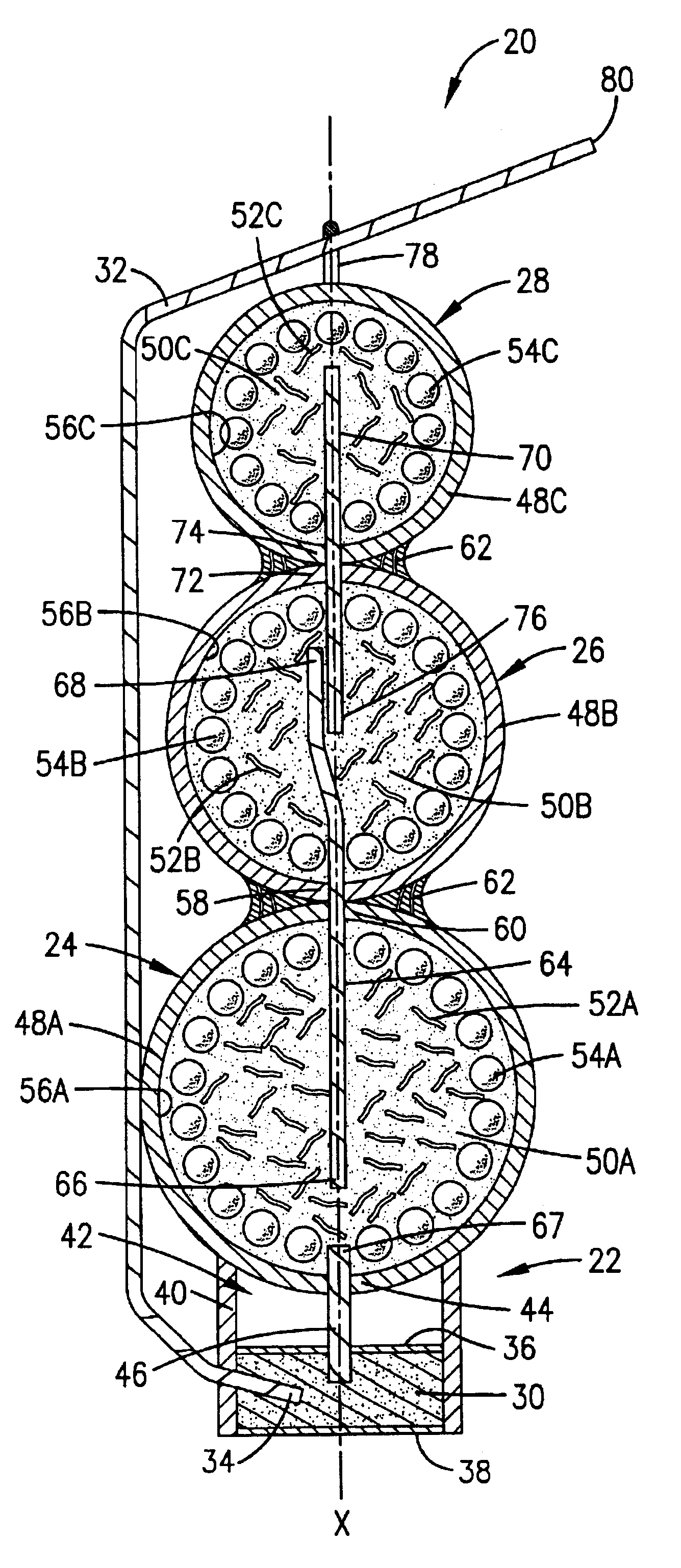

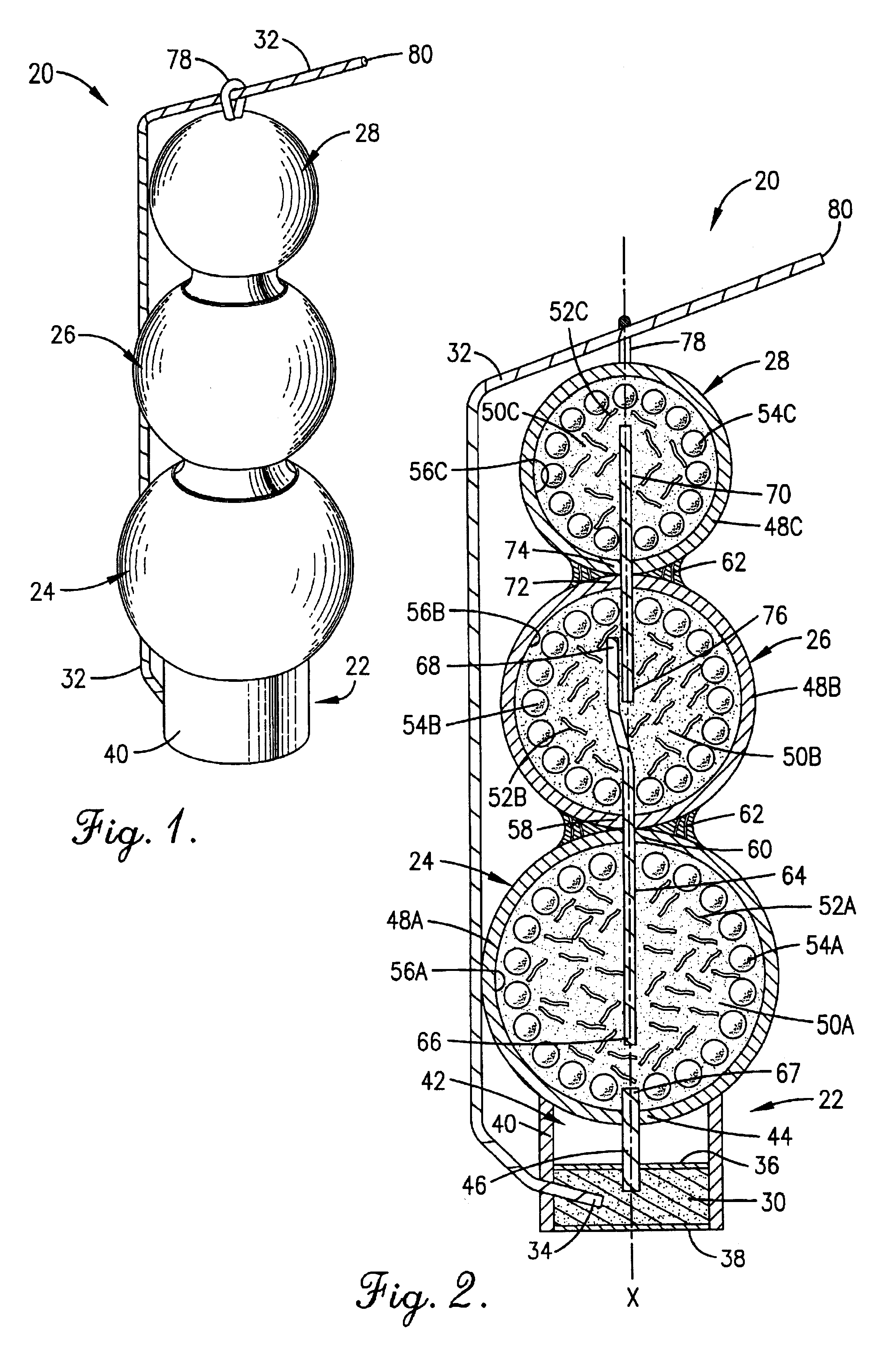

Referring to the drawings in greater detail, FIGS. 1 and 2 show a multiple effect pyrotechnic shell 20 constructed in accordance with a preferred embodiment of the present invention. The shell 20 broadly includes a lift chamber 22, primary break 24, secondary break 26, and tertiary break 28. The lift chamber 22 and breaks 24-28 are weighted to inhibit tumbling, thereby reducing the occurrences of ground explosions while providing the capability to display at least three effects.

The lift chamber 22 contains a lift charge 30 sized to project the shell to a sufficiently high altitude for explosion of the breaks 24-28. An elongated and external safety fuse 32 has a terminal end 34 embedded in the lift charge 30. The lift charge 30 and terminal end 34 of the external fuse 32 are held between upper and lower closures 36, 38 and an outer cylindrical wall 40 which attaches to the primary break 24. An open area 42 is preferably left between the upper closure 36 and the bottom 44 of the prima...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com