Dispensing cap with gripping means

a technology of gripping means and gripping cap, which is applied in the field of gripping cap, can solve the problems of not always easy to locate the gripping zone, the risk of hitting the user's thumb, and the difficulty of locating the gripping zone, so as to achieve reliable stoppering action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

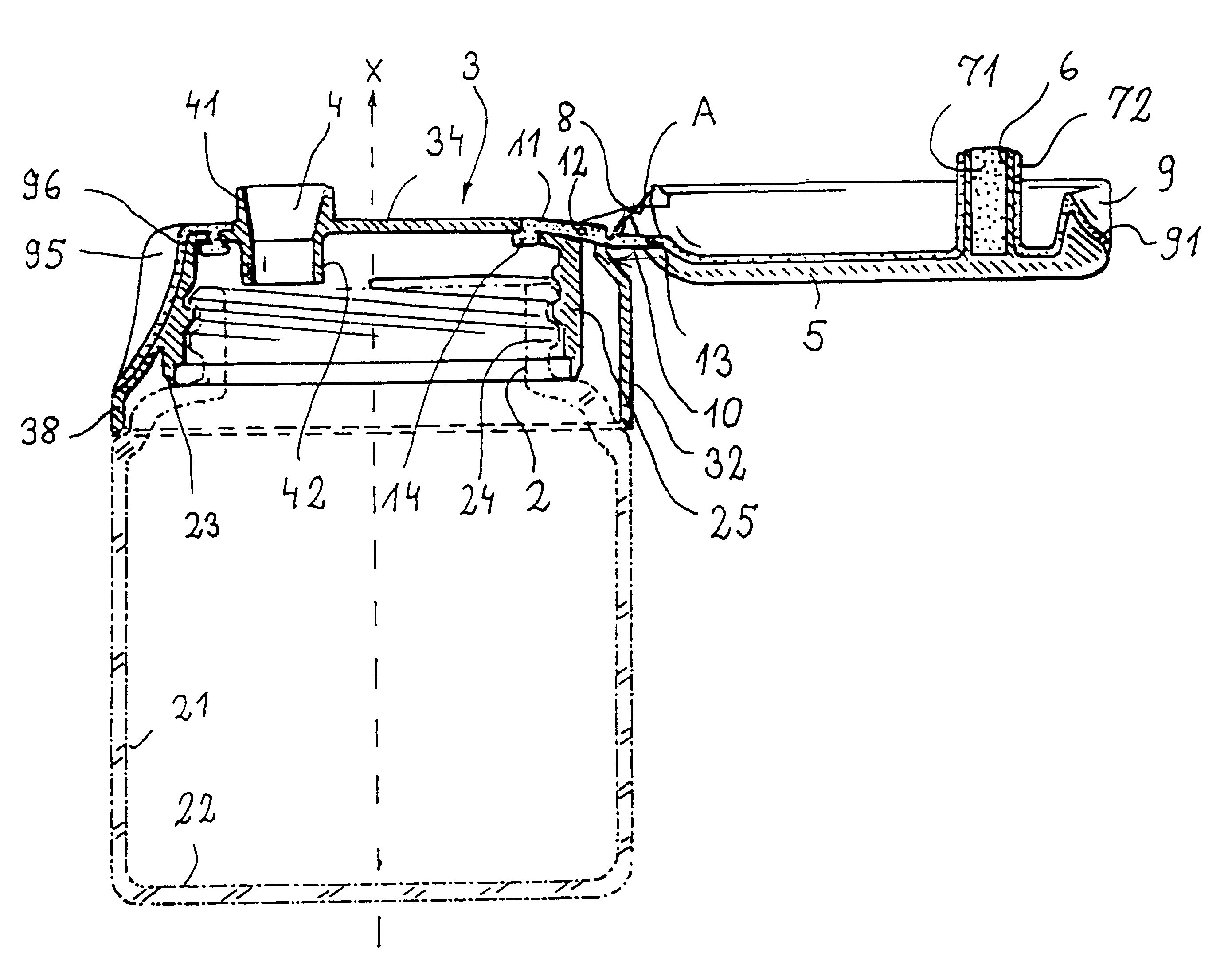

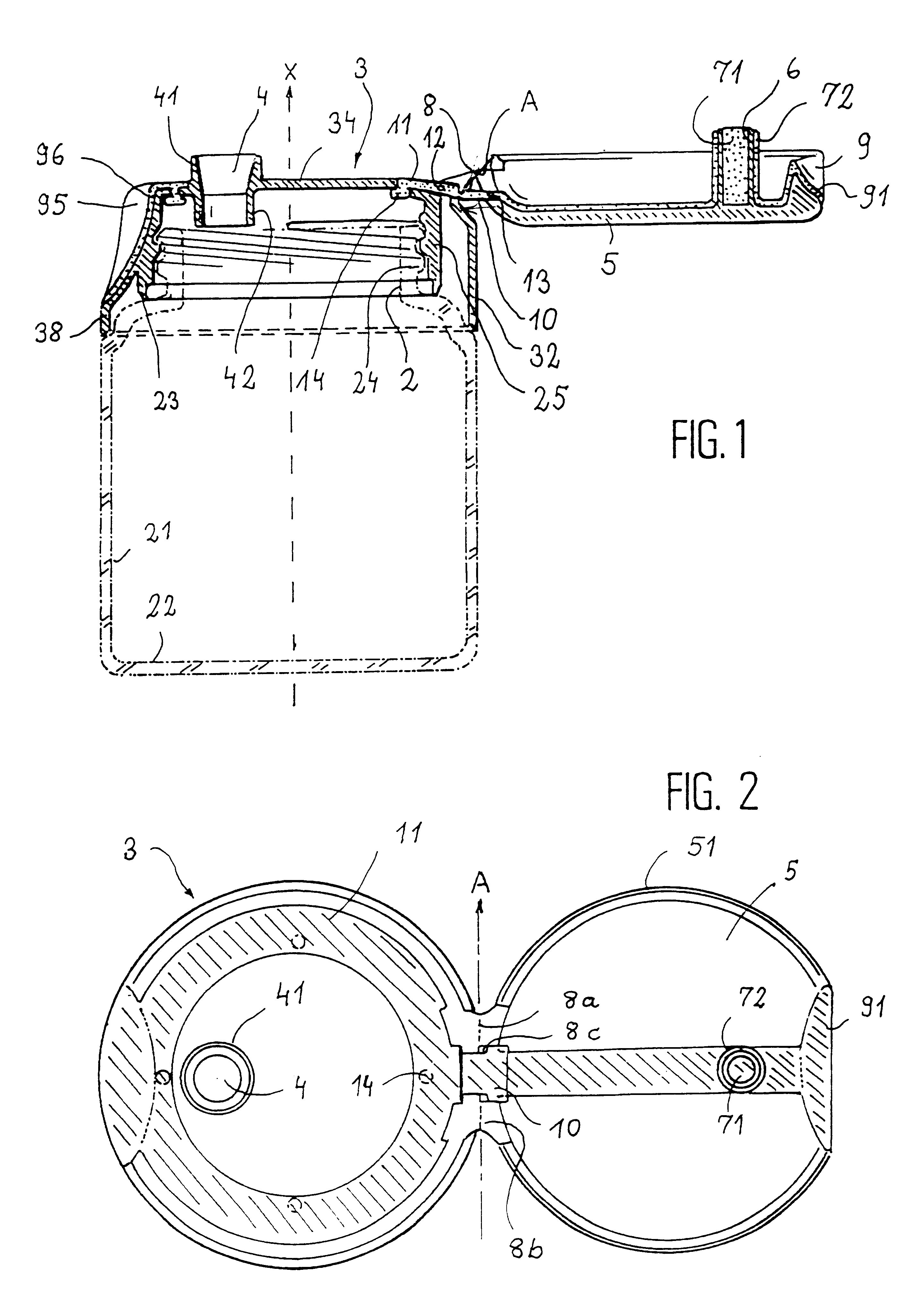

[0024]Referring to FIGS. 1 and 2, a dispensing unit comprising a reservoir 21 having a longitudinal axis X is equipped with a dispensing cap 3 provided with a body 32. The reservoir 21 has a closed bottom 22 and, at the end opposite side to the bottom, a neck 2 provided with an external thread 24 for fixing the cap body 32 on the reservoir. For this purpose, the cap body has an internal cylindrical skirt 25 provided with an internal thread complementary to the thread 24 of the neck 2. The reservoir 21 has a generally circular or oval cross-section, but the cross-section may be of any other shape, for example, polygonal or asymmetrical. It is made, for example, of high density polyethylene. As for the body of the cap, it is made of a rigid or semirigid material, such as polypropylene.

[0025]The body 32 of the cap 3 has a plate 34 provided at its circumference with a film hinge 8, by means of which a lid 5 is articulated to the cap, allowing the lid to pivot around an articulation axis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com