Mower head with movable guard

a technology of rotary cutter and guard, which is applied in the field of mower heads, can solve the problems of reducing the cutting width of the blade, so as to achieve the effect of convenient access

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

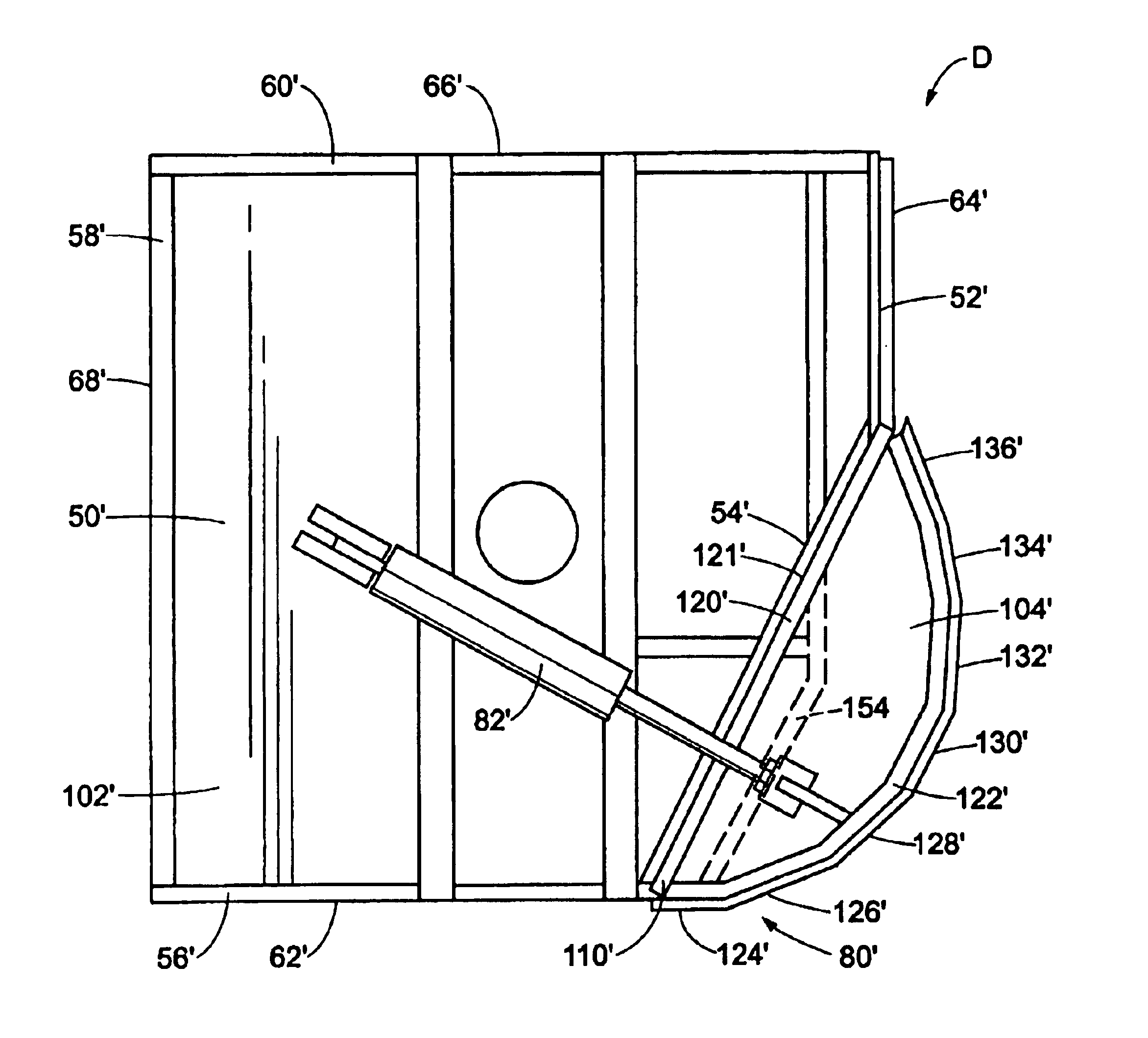

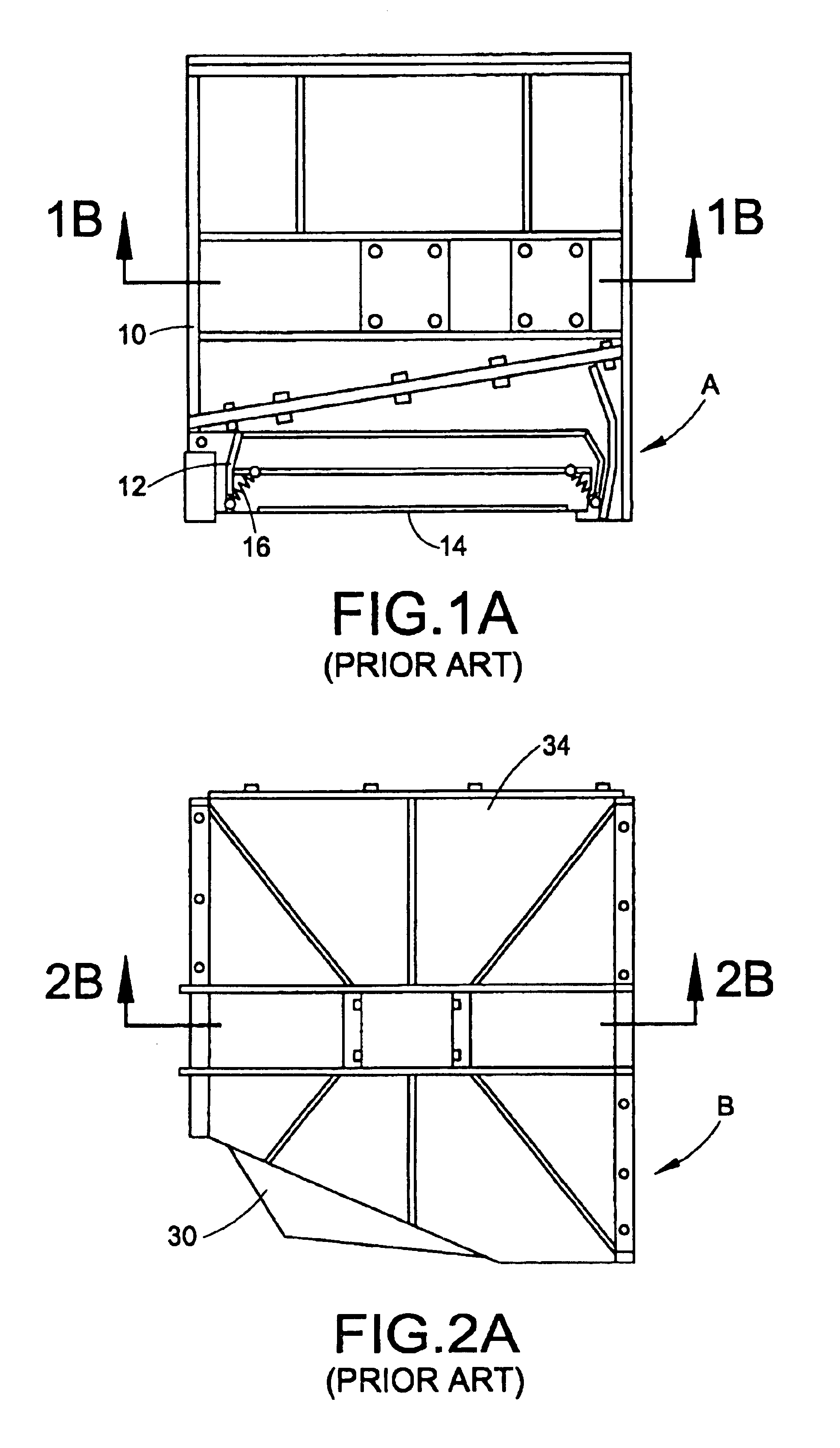

[0036]Referring now to the drawings, wherein the showings are for purposes of illustrating preferred embodiments of this invention only and not for purposes of limiting same, FIG. 3A shows a mower head C according to a first preferred embodiment of the present invention.

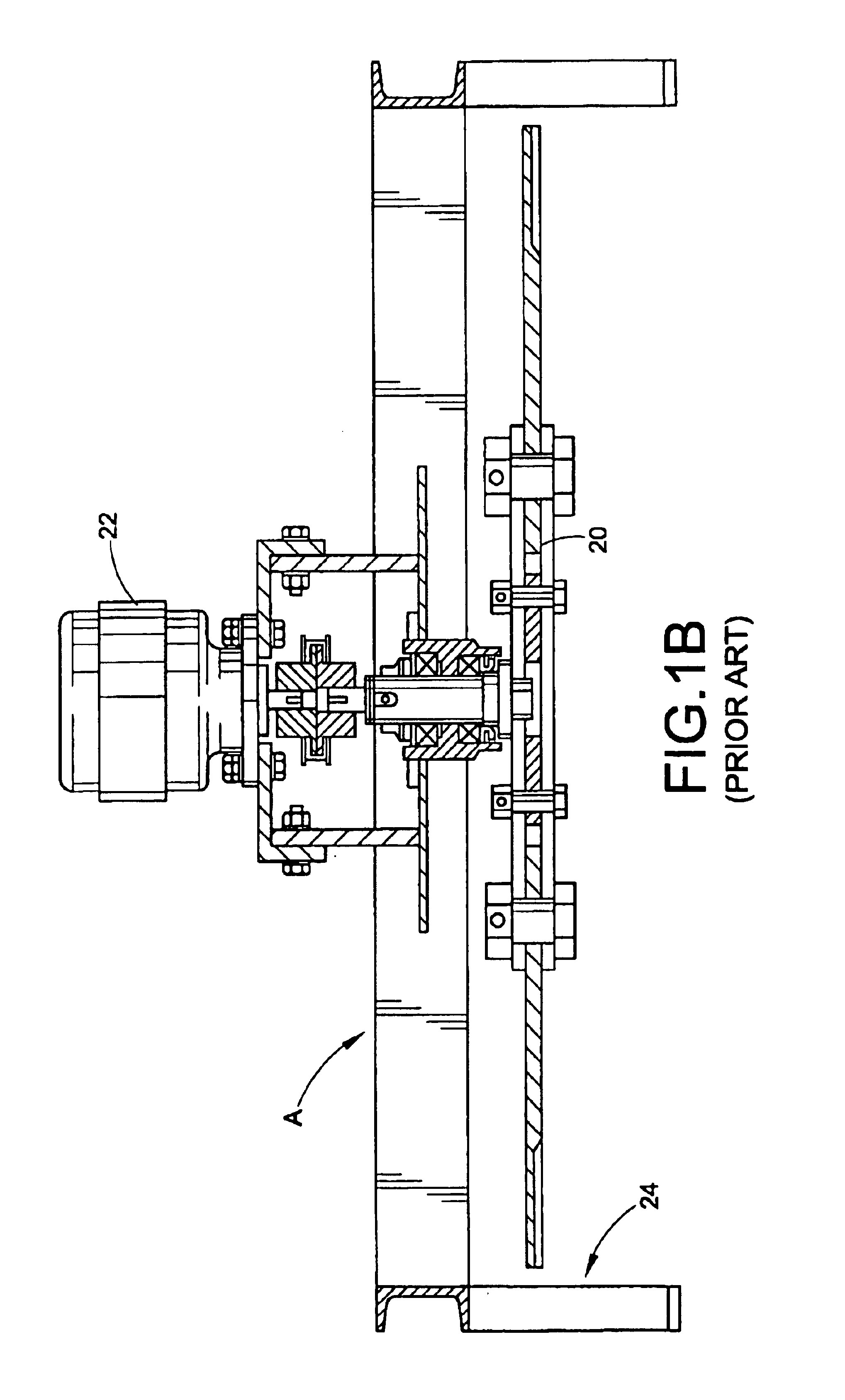

[0037]A mower includes a prime mover, such as a tractor (not shown), which is self-propelled to move at least in forward and rearward directions. An arm assembly (not shown) is operatively connected at one end with the prime mover and at the other end with the mower head. A positioning control means, such as a plurality of hydraulic cylinders, controls the position of the arm assembly relative to the prime mover and the mower head. In this manner, the position and orientation of the head is selectively variable. The arm assembly can be a boom assembly which includes at least two pivotally connected arms, one of which is pivotally connected with the prime mover and the other of which is pivotally connected with the mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com