Multiple signature feeder system

a feeder system and signature technology, applied in the field of binding lines, can solve the problems of limited capacity of the binding line, inability to add packer boxes beyond a certain number, and inability to meet the requirements of a certain number of boxes, so as to achieve the effect of expanding the capacity and flexibility of the conventional binding lin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017]The following detailed description is not intended to limit the scope of the invention to the precise form disclosed. Instead, the embodiment illustrated herein has been chosen and described in order to best explain the principles of the invention so that others skilled in the an may follow its teachings.

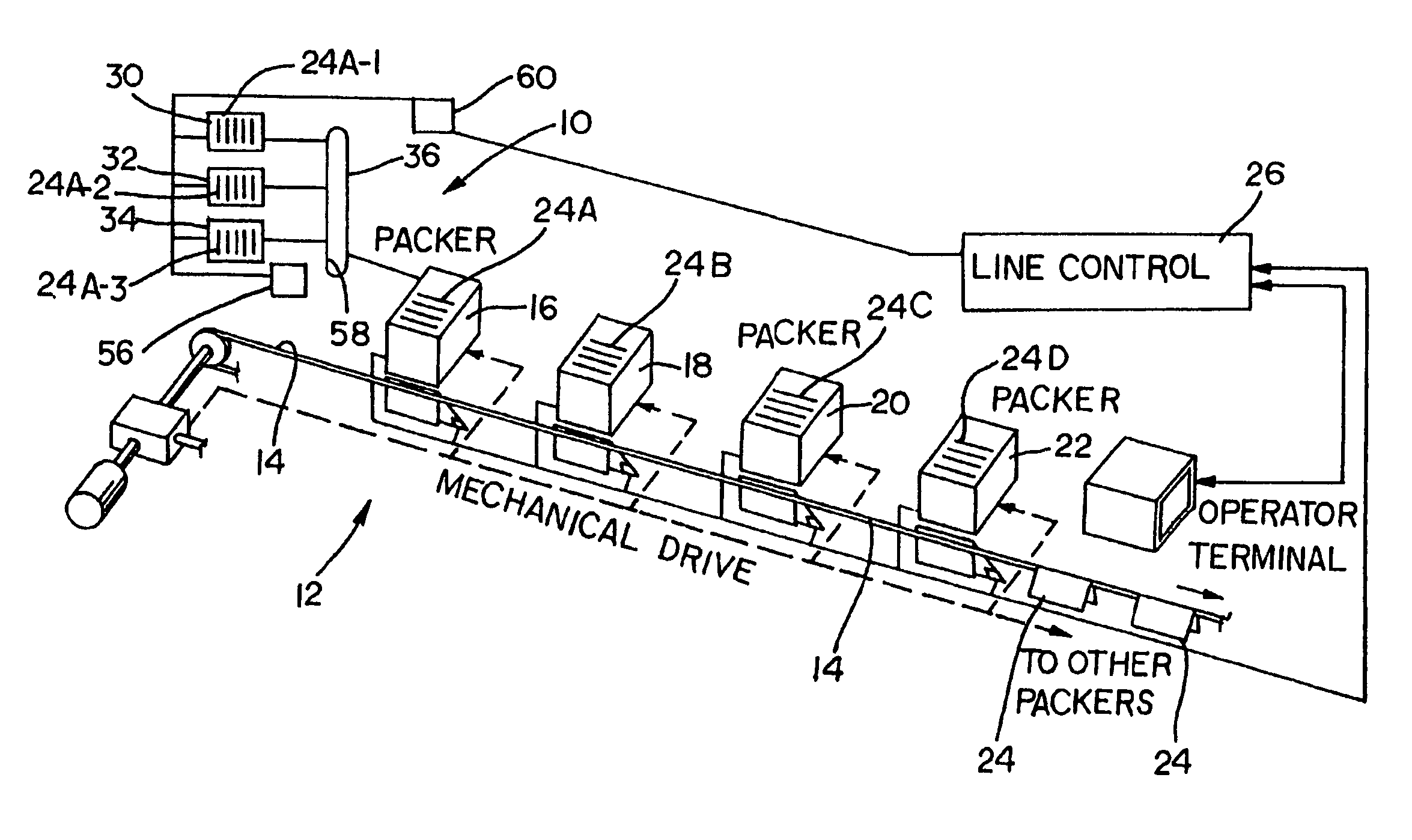

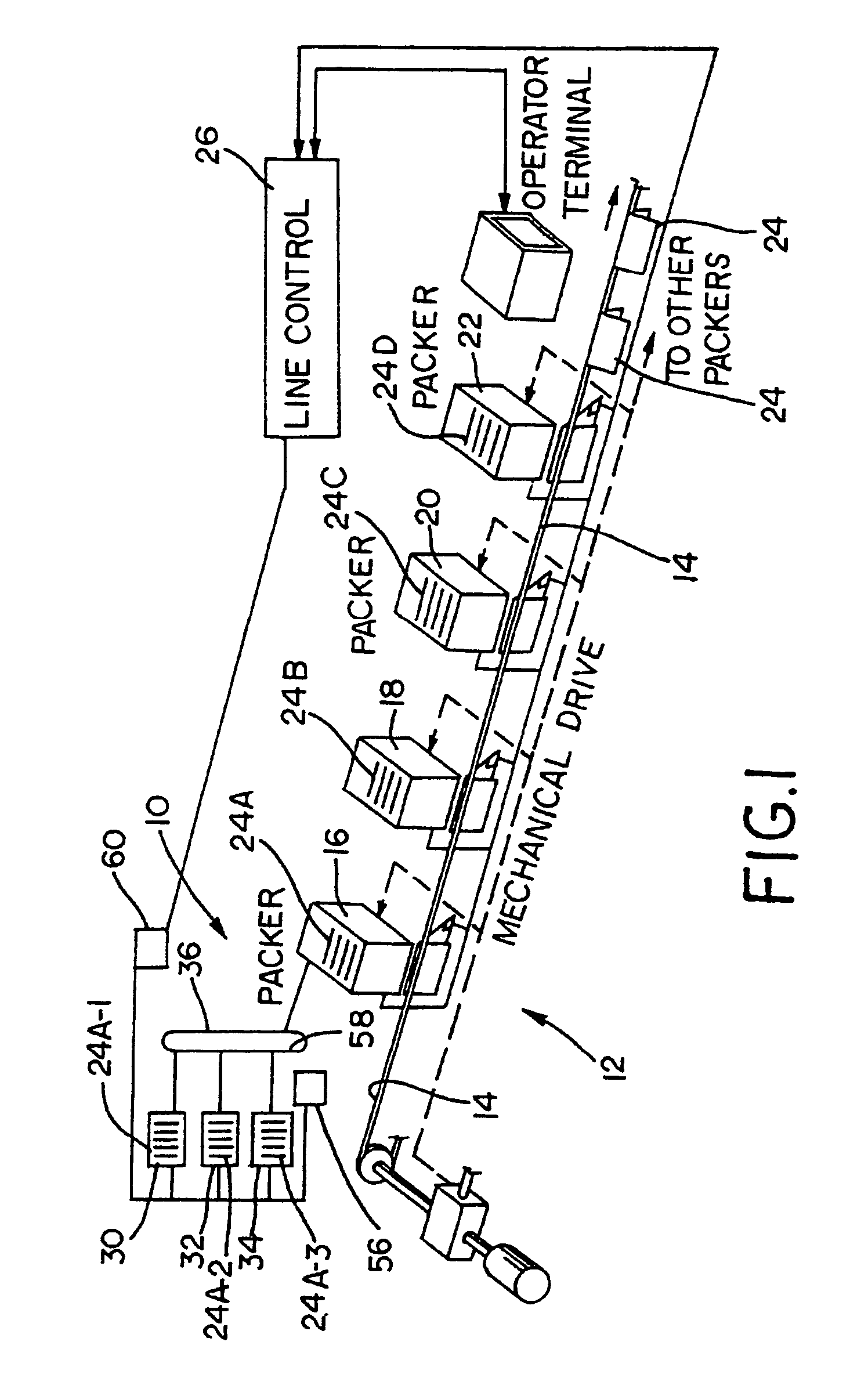

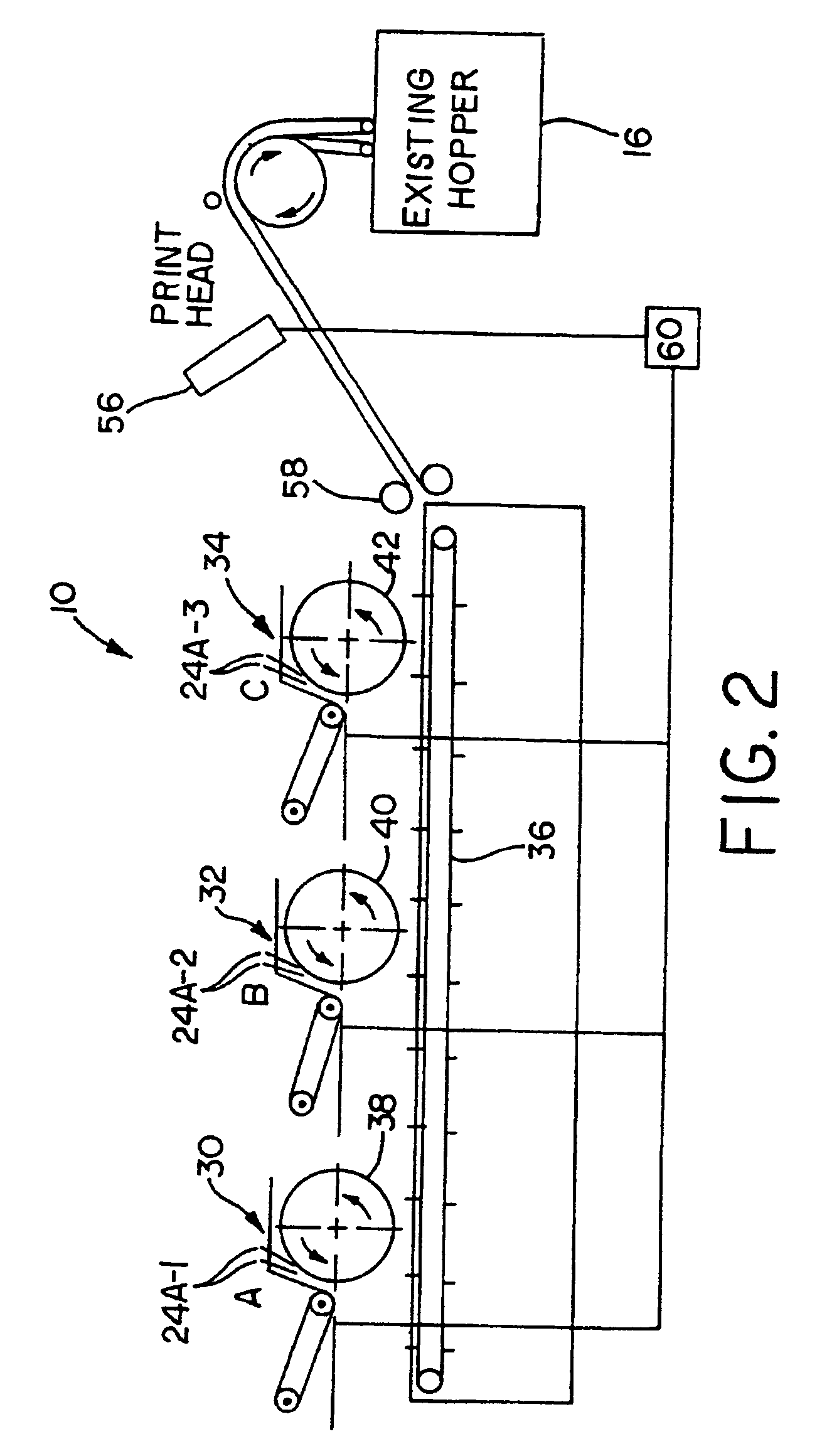

[0018]Referring now to the drawings, a feeder system incorporating the features of the present invention is generally referred to by the reference numeral 10, and is shown operatively connected to a binding line 12 of the type commonly employed in the art. Binding line 12 includes a gathering chain or conveyor 14 which is moveable past a plurality of packer boxes 16, 18, 20, 22, etc. The gathering conveyor 14 includes a plurality of chain spaces (not shown), each of which is adapted to gather a signature 24 (shown in FIG. 3) from at least some of the packer boxes 16, 18, 20, 22, etc., in seriatim fashion. Although only four packer boxes 16, 18, 20 and 22 are shown, it will be ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com