Small-sized precise hand operated grinding and polishing apparatus

A precise and manual technology, applied in the direction of manufacturing tools, grinding devices, grinding machine tools, etc., can solve the problems that the surface of the electrode cannot be guaranteed to be smooth and clean, the shape of the electrode surface is difficult to ensure, and the workload is large, so as to improve the accuracy and data. The effect of reliability, simple structure and safe use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

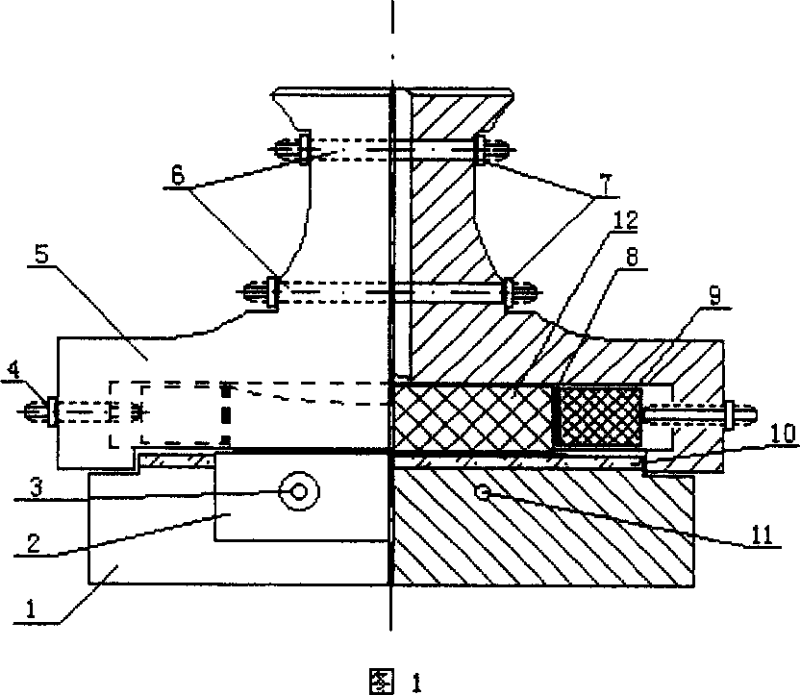

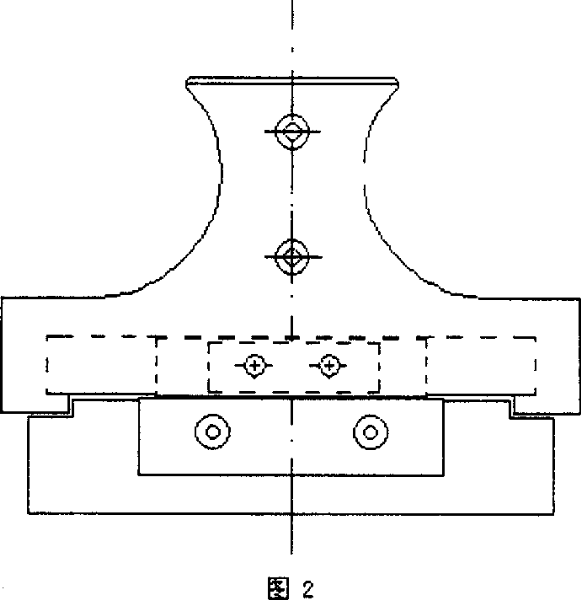

[0015] Further illustrate the present invention below by embodiment and accompanying drawing.

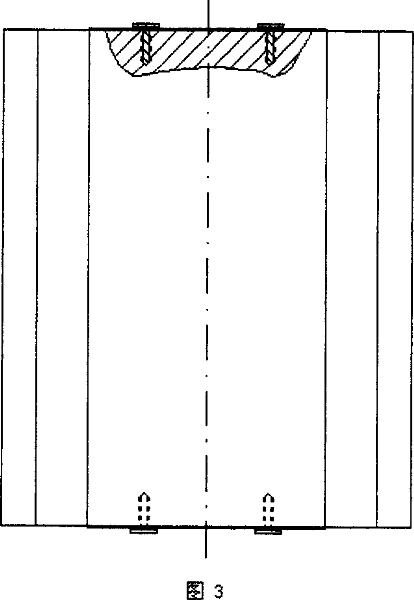

[0016] The present invention is composed of two major parts, a platform 1 and a style fixing body 5, wherein the style fixing body 5 is completely identical and symmetrically arranged, and can hold a style in two parts, connected and fixed by fastening screws 6 and fastening nuts 7 As a whole, the whole is a pliers (or clamp) structure with a handle. The lower part of the two-part mechanism is symmetrically provided with opening grooves that can accommodate styles. The shape of the opening grooves is circular; Sheet 8, clamping block 9 and pattern 12 are fastened in pattern fixed body 5 by fastening screw 4. Flat plate mechanism 10 is placed on platform 1 (plate mechanism can be mirror plate or glass plate, and present embodiment adopts mirror plate), emery cloth or sandpaper 2 are tiled on mirror plate, and integral body forms boss on platform 1, and its The two sides are folded t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com