Woods and wooden composite material shearing modulus non destructive checkers

A composite material and shear modulus technology, applied in the direction of measuring devices, wood testing, material inspection products, etc., can solve the problems of waste, time-consuming, expensive, etc., to ensure product quality, convenient and fast operation, and good detection effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

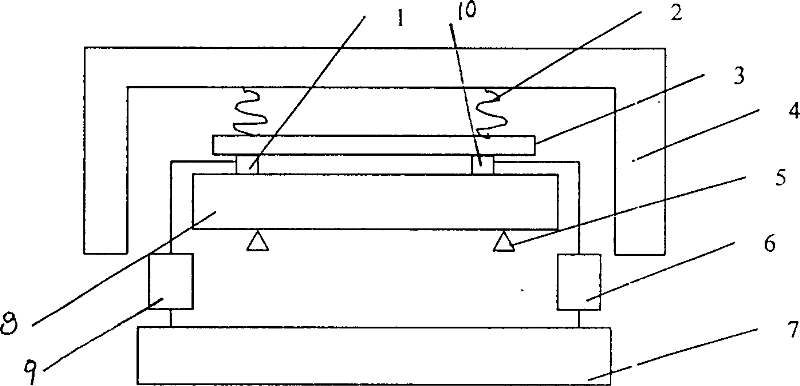

[0009] The best embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings. The non-destructive testing device for shear modulus of wood and wood composite materials includes sensors 1 and 10, signal amplifiers 9 and 6, and a fast Fourier transform (FFT) analyzer 7, and a compression spring 2 is installed on the inner upper wall of the frame 4, and a plastic plate 3 The end face is connected with the lower end face of the compression spring 2, and the plastic plate 3 is installed inside the frame 4; the left sensor 1 and the right sensor 10 are installed on the left and right sides of the lower end face of the plastic plate 3 respectively; the foam support block 5 is equipped with Installed below the left and right side sensors 1 and 10; the wires respectively connect the left side sensor 1, the left side signal amplifier 9, the fast Fourier transform FFT analyzer 7 and the right side sensor 10, the right side signal ampl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com