A detection device and detection method for depth information of optical element subsurface defects

A sub-surface defect and depth information technology, which is applied in the field of detection devices for sub-surface defect depth information of optical components, can solve problems such as low detection efficiency, difficult positioning, secondary damage, etc., to improve detection speed and reduce difficulty, improve The effect of detection speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below with reference to the drawings and embodiments.

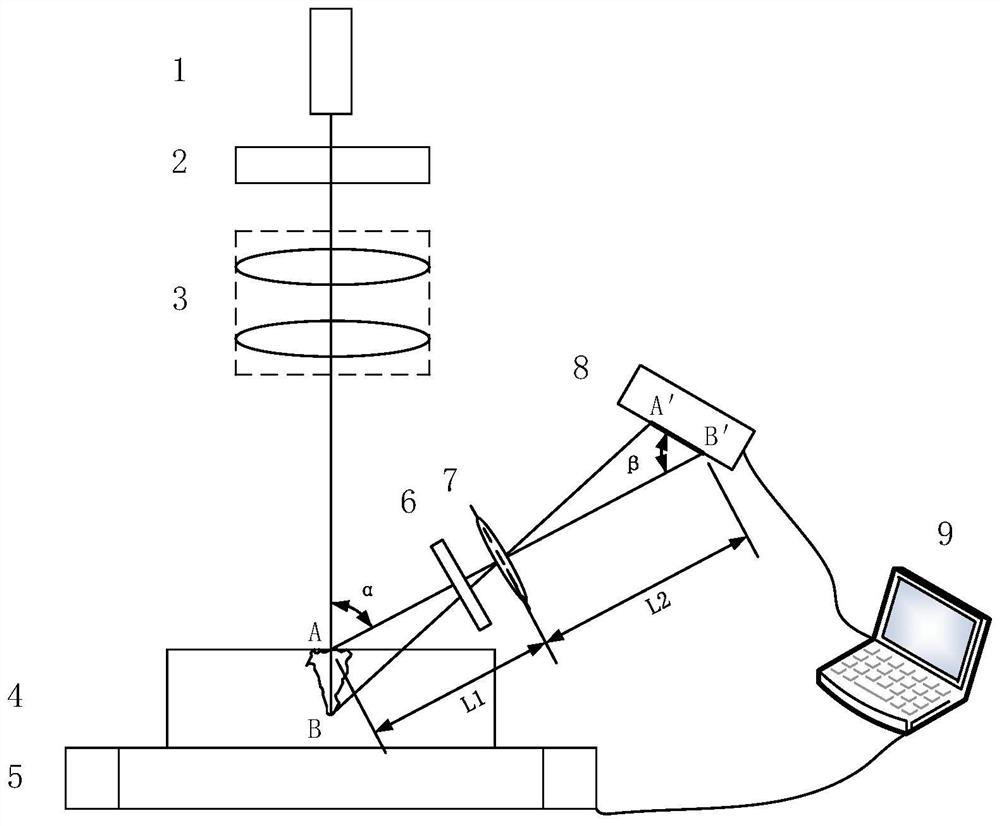

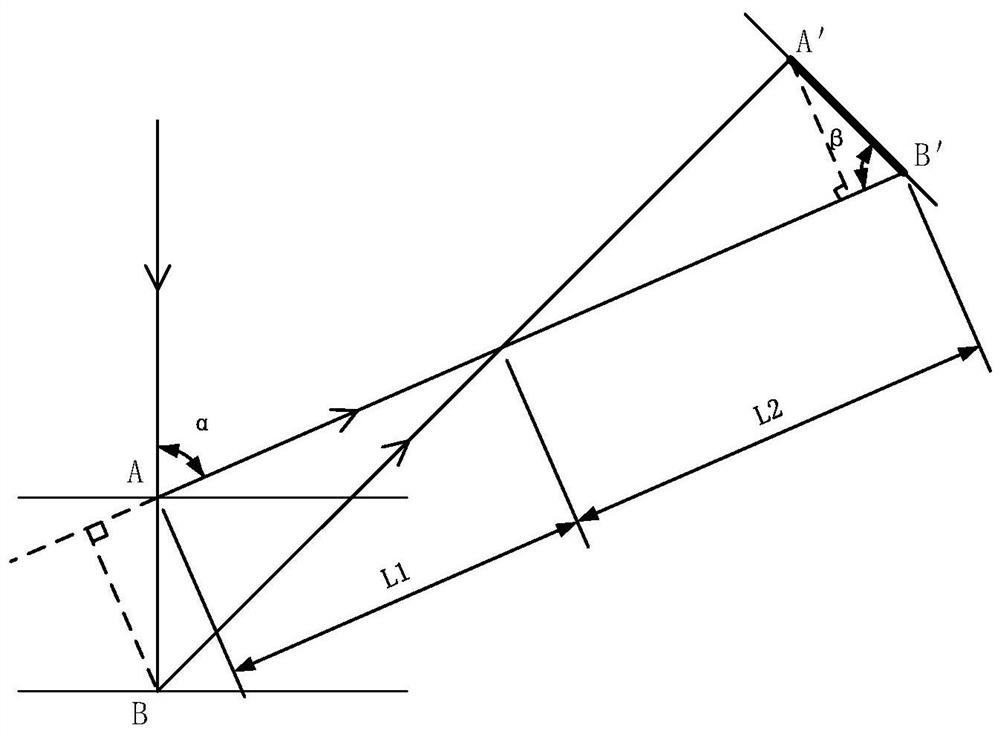

[0018] see figure 1 , a non-destructive optical element sub-surface defect depth detection device provided by the present invention is mainly composed of three parts: a light source modulation component, a defect depth detection component, a two-dimensional mobile platform, and a computer control platform. The light path of the light source modulation component Arranged perpendicular to the two-dimensional mobile platform 5, it includes an ultraviolet laser 1, a narrow-band filter 2, and a beam shaping component 3 from top to bottom; the optical path of the defect detection component and the light path of the light source modulation component are arranged at an angle, including A narrow band filter 6, a microscope lens 7 and a CCD detector 8; a computer control platform 9 is connected to the CCD detector 8 and the two-dimensional mobile platform 5 respectively.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com