Fuel jet valve

A technology for fuel injection valves and valve seats, which is applied to fuel injection devices, injection devices, charging systems, etc., and can solve problems such as expensive sound insulation materials and increased manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

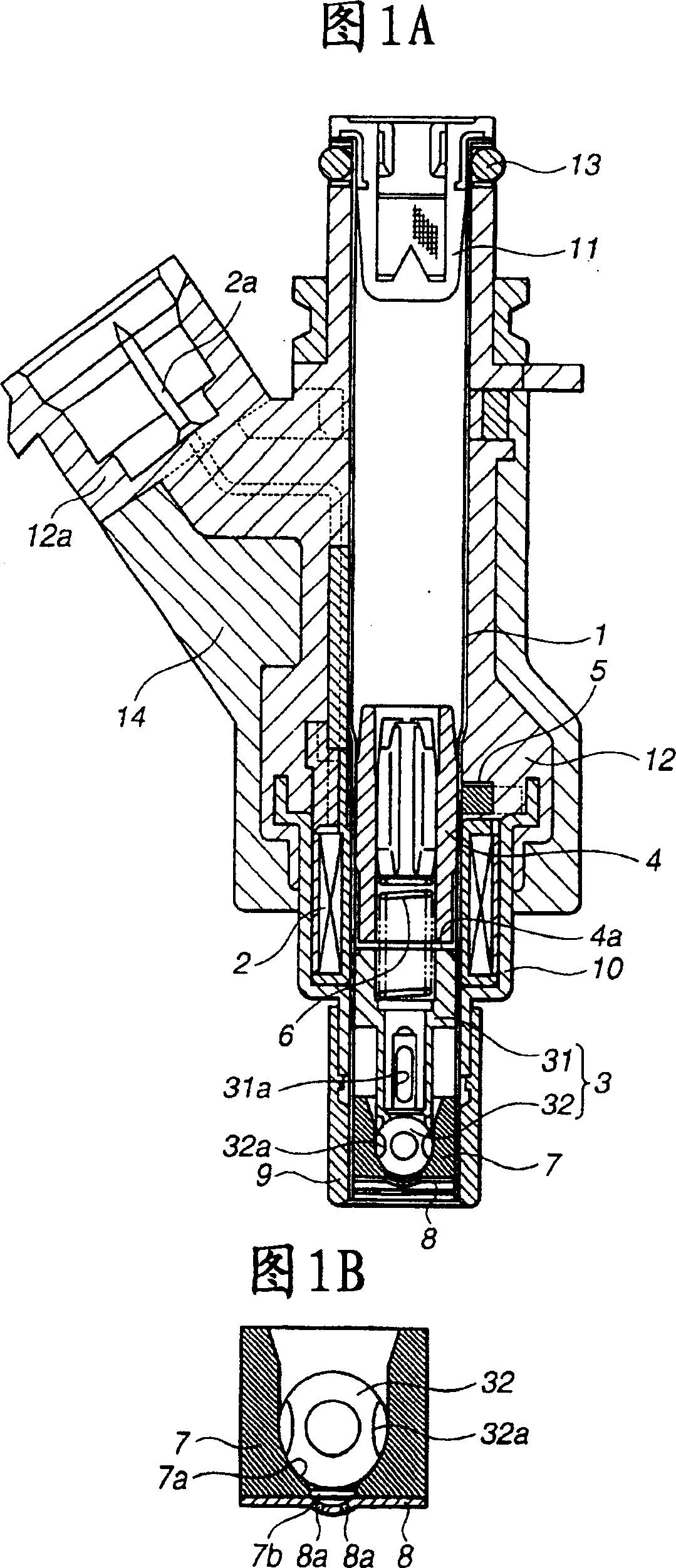

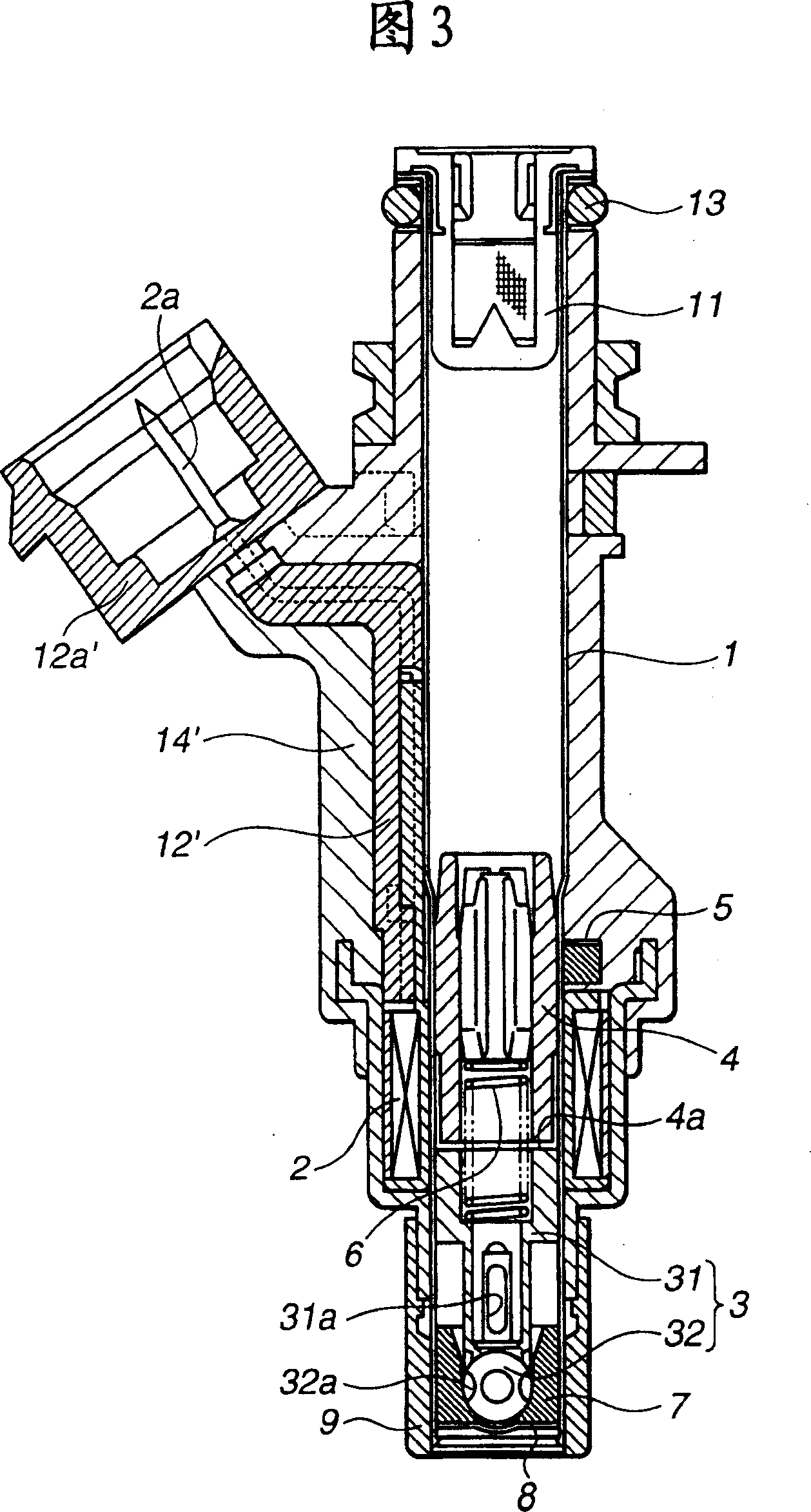

[0019] Referring to the drawings, a fuel injection valve for an internal combustion engine embodying the present invention will be described.

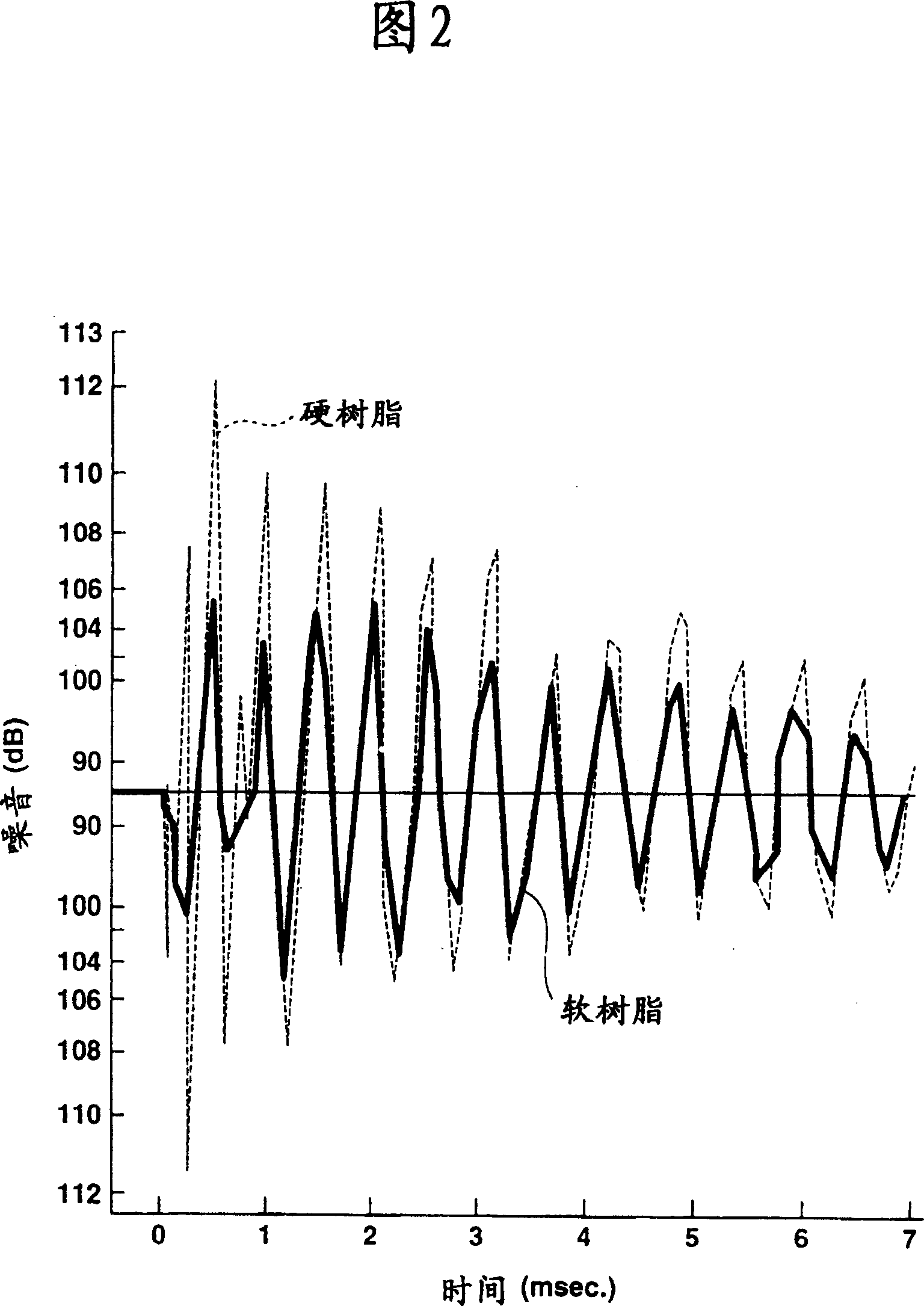

[0020] Referring to Figures 1A-2, a first embodiment of the present invention is shown. 1A and 1B, the fuel injection valve includes: a tubular housing 1, which is formed of a magnetic material such as metal; an electromagnetic coil or actuator 2, which is fixedly mounted on the outer edge of the housing 1; and a valve element 3 , which is axially and slidably arranged to pass through the housing 1, and includes a tubular holder 31 and a ball 32, which are integrally formed by welding. A fuel outlet 31 a is formed on a lower edge wall of the holder 31 . The ball 32 has flat surfaces 32 on the edges, which are obtained by machining.

[0021] A tubular spring housing 4 is fixedly mounted on the inner wall of the housing 1 above the valve element 3 (holder 31 ), as shown in FIG. 1A , while defining a predetermined gap therebetween. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com