Method for preparing low-heating-value lamp protection cover

A low calorific value, protective cover technology, applied in vacuum evaporation coating, ion implantation coating, metal material coating process and other directions, can solve the problems of human body discomfort and inability to reflect heat, improve reflectivity and reduce heat The effect of overflowing and avoiding human discomfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

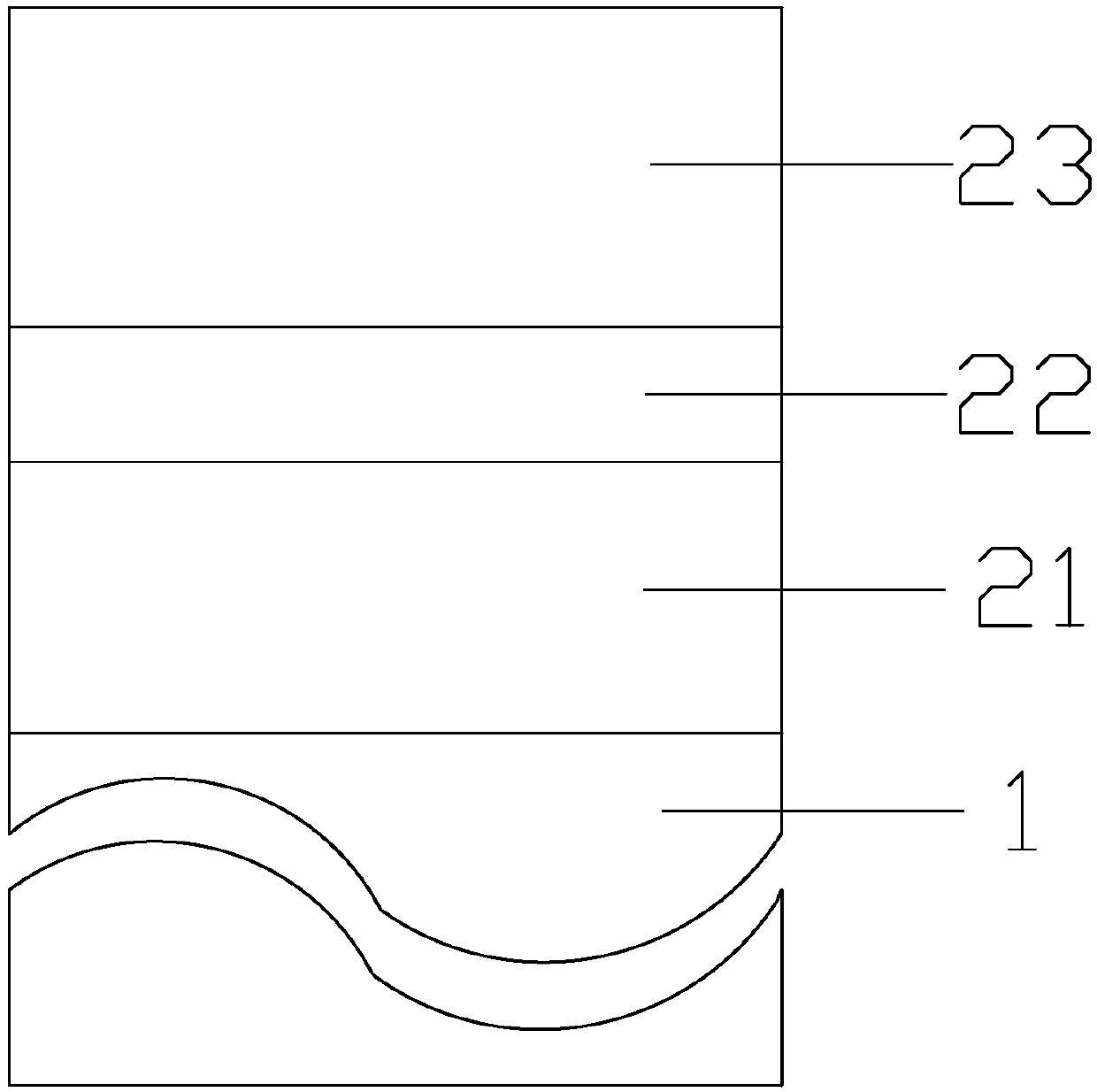

[0028] See figure 1 , a method for preparing a protective cover for a low-calorie lamp, comprising the following steps:

[0029] (1) In the first step, the lampshade substrate 1 is cleaned.

[0030] Preferably, the lampshade substrate 1 is ultrasonically cleaned in acetone for 10 minutes, then ultrasonically cleaned with ethanol for 10 minutes, and finally ultrasonically cleaned in deionized water for 10 minutes.

[0031] (2) In the second step, the cleaned lampshade substrate 1 is dried, put into a magnetron sputtering tray, and then sent into a coating machine.

[0032] (3) The third step, coating, comprises the following steps:

[0033] A. The dried lampshade substrate 1 is subjected to target-free plasma bombardment in the first chamber of the coating machine to realize degassing of the lampshade surface.

[0034] B. Magnetron sputtering the aluminum oxide layer 21 on the lampshade substrate 1, using oxygen as the reaction gas, argon as the protective gas, and sputterin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com