Transport installation for paper reels, method for its operation and vehicle

A technology for vehicles and conveying devices, which can be used in storage devices, transportation and packaging, two-dimensional position/channel control, etc., and can solve problems such as not necessarily dragging force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

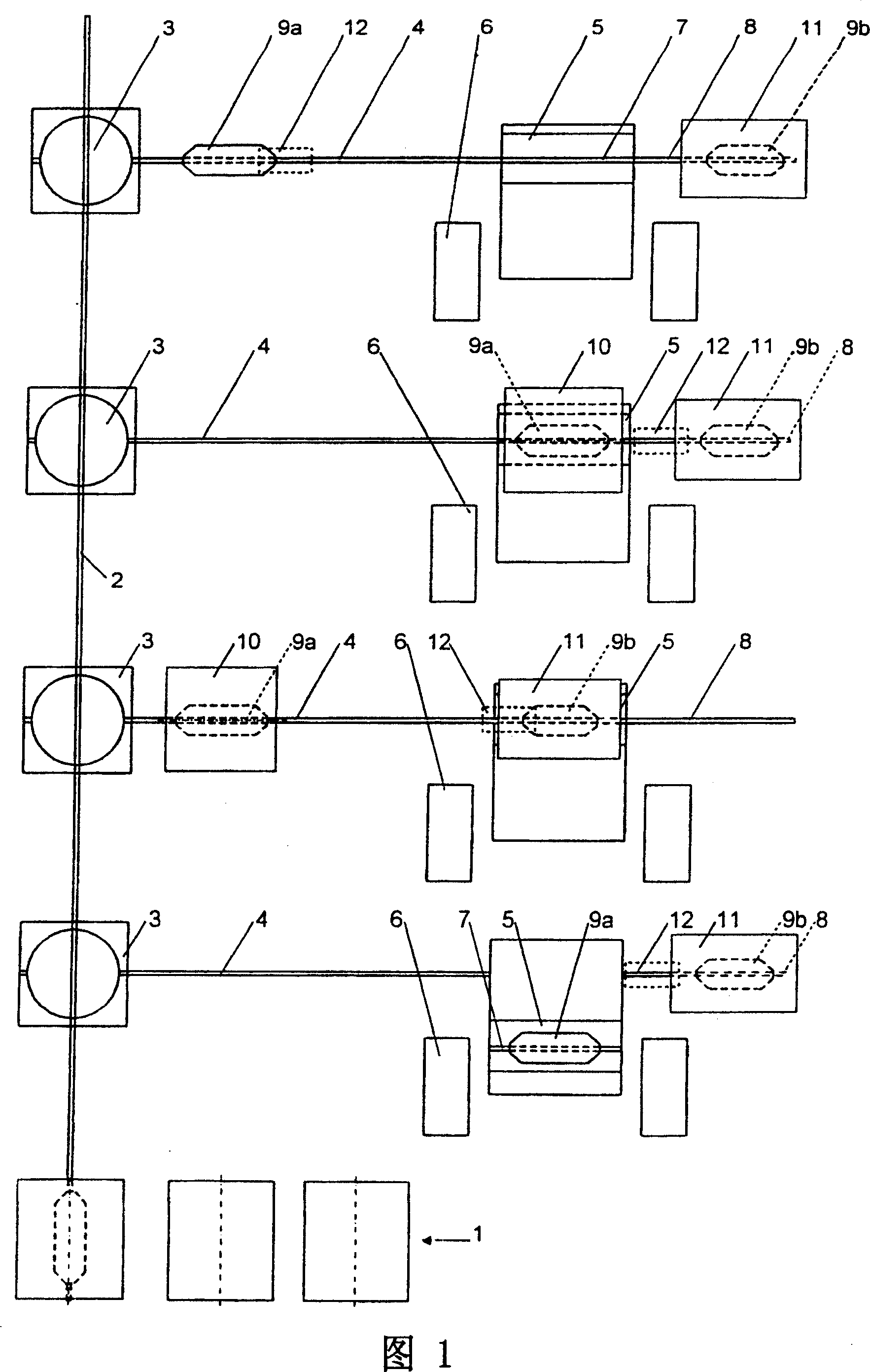

[0029] The conveyor device of the invention (FIG. 1) comprises a roll accumulator, in particular a buffer accumulator 1, for holding unwrapped paper rolls provided with adhesive sheets, i.e. ready for roll replacement, straight transport track 2 from The accumulator is guided by a plurality of turntables 3 at each of which a loading rail 4 leading to a sliding platform 5 or a lifting platform of a reel 6 extends at right angles. When the sliding platform 5 is in the transfer position, the loading rail 4 is flush on the delivery side of the sliding platform 5 with the rail portion 7 thereon. On the side facing away from the conveying side, there is an adjacent storage track 8 flush with the loading track 4 .

[0030] A non-driven carriage 9a which can receive a paper roll 10 can travel on each of the loading rails 4, and a paper roll core carriage 11 for accommodating a depleted paper roll core is provided normally resting on the storage rail 8 on the other non-drive bracket 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com