Head clamping mechanism of opening power pincers

A clamping mechanism and power tong technology, applied in the field of power tongs, can solve the problems of increased pipe surface damage, failure of clamping action, deterioration of tooth plate strength, etc., achieving significant social and economic benefits, simple clamping mechanism, Easy to process effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

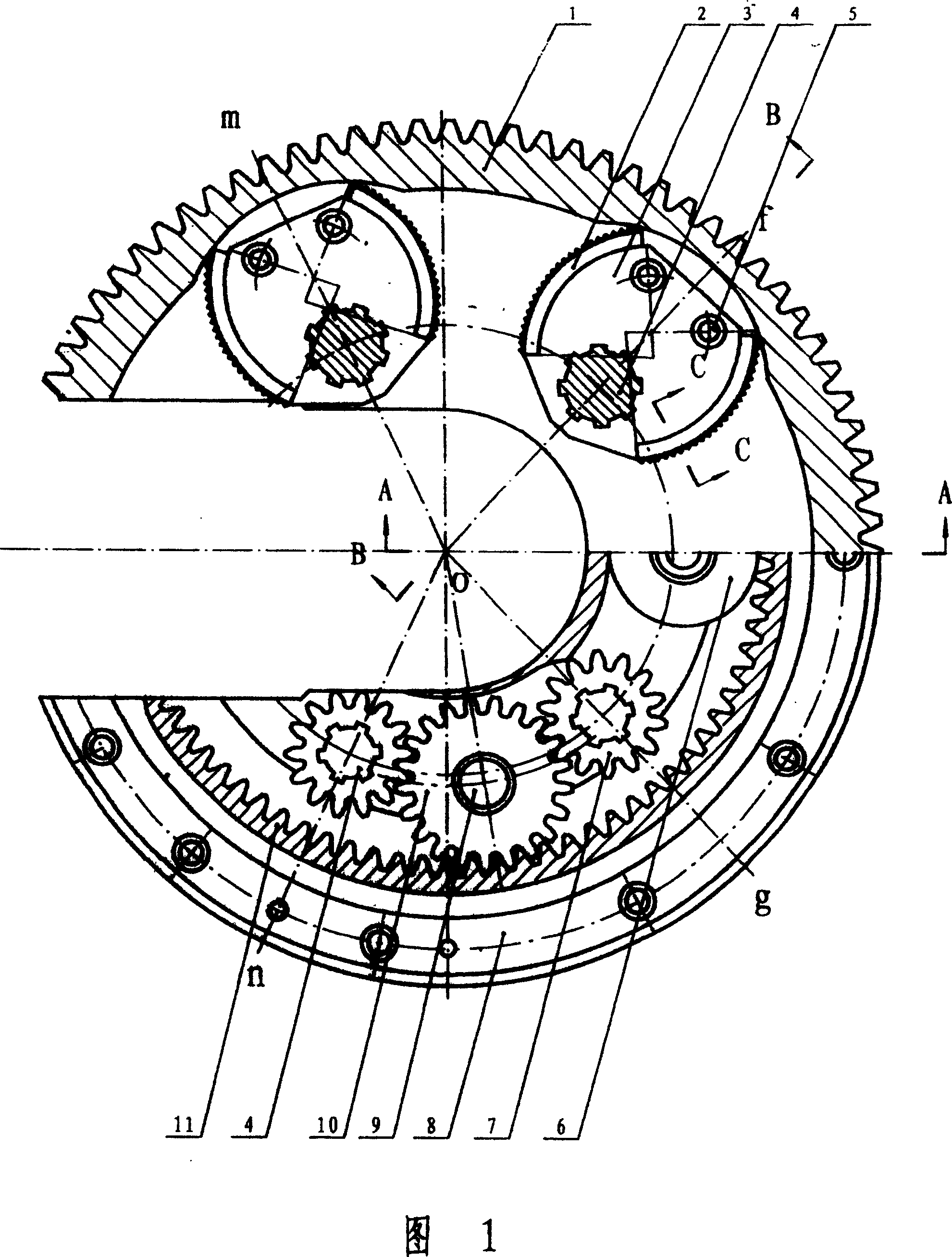

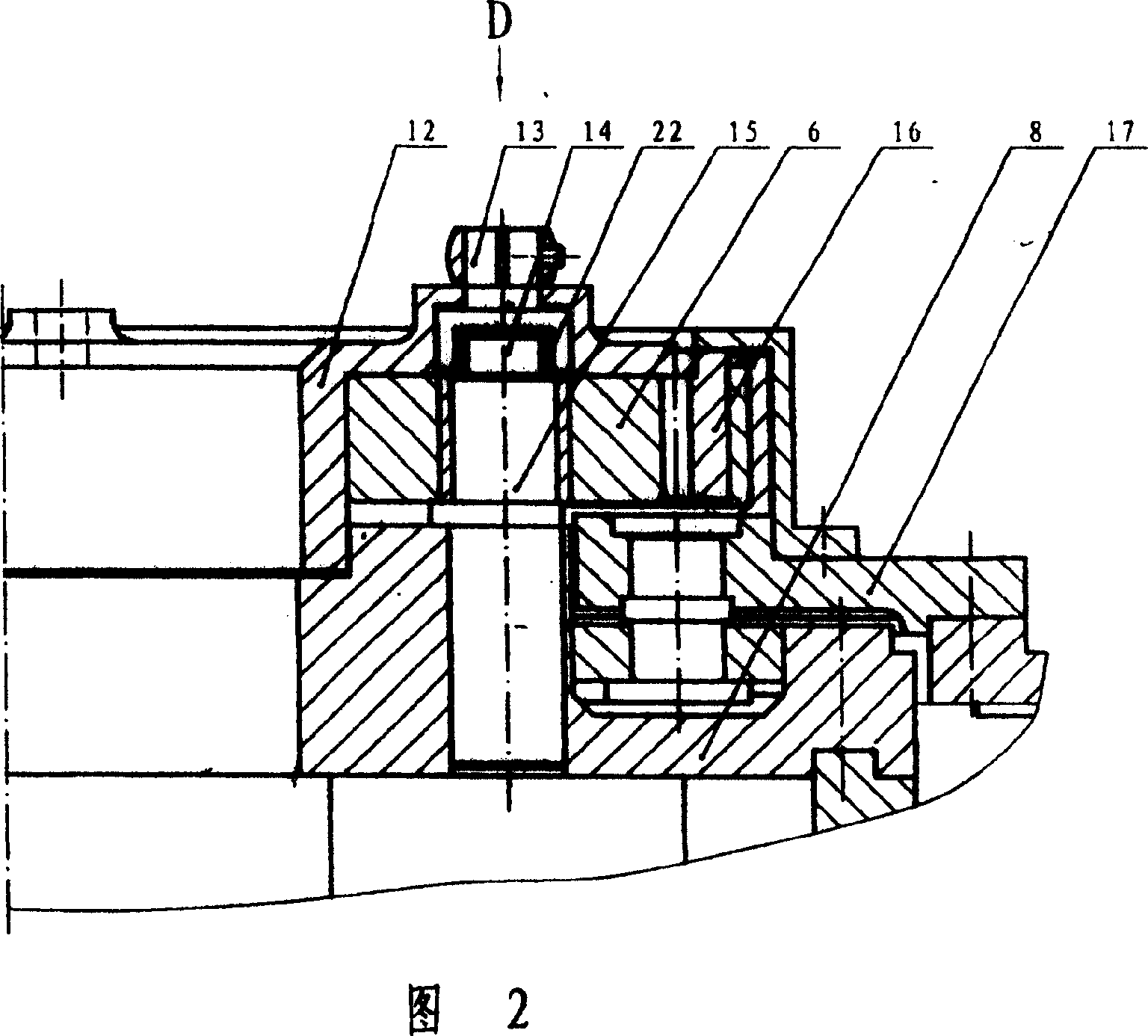

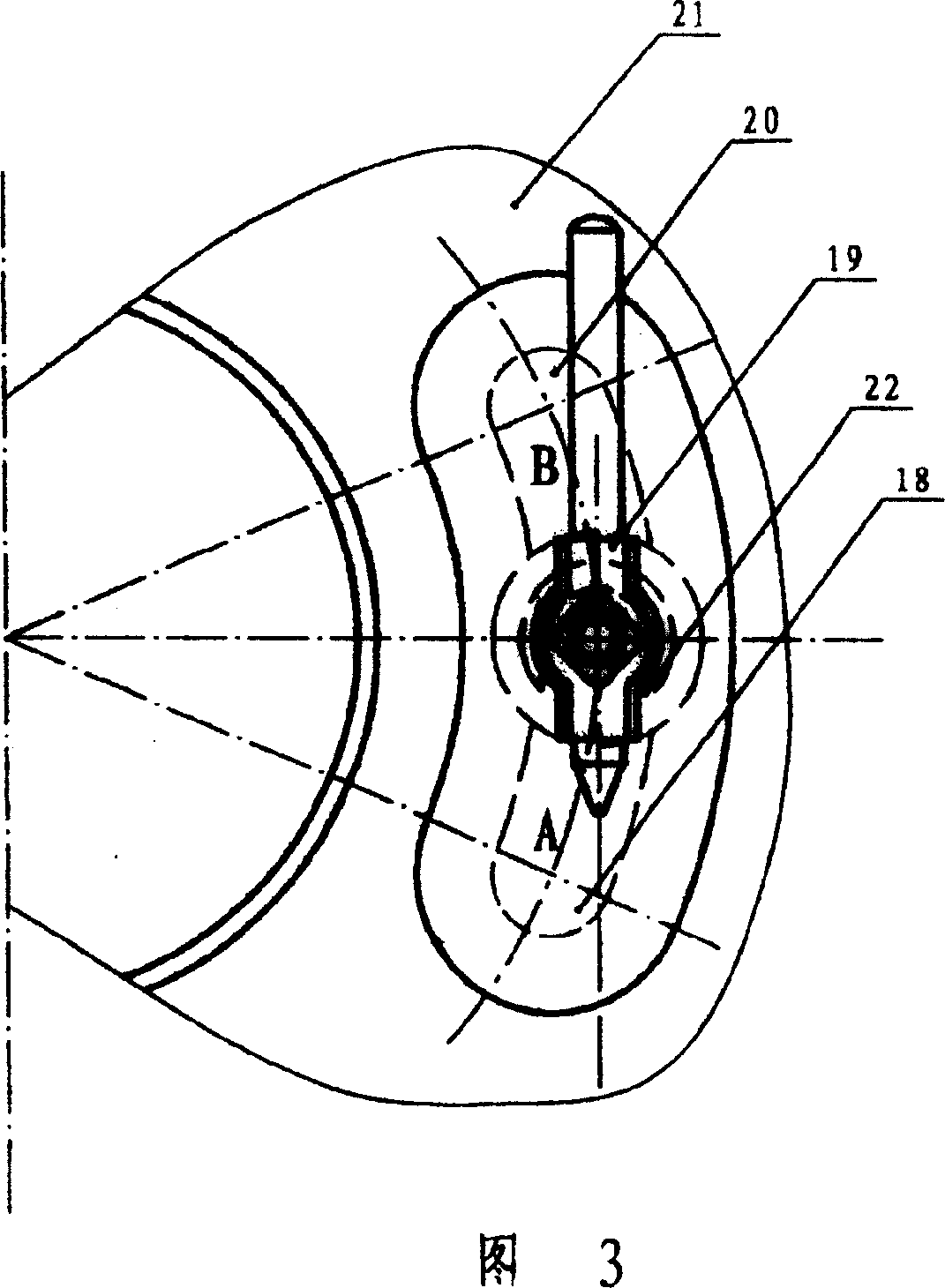

[0012] As shown in Figures 1, 2, 3, and 4, an open-type power tong main tong clamping mechanism mainly consists of an open gear cover 8, an open gear 1, a butterfly jaw plate 3, an outer curved tooth plate 2, and a planet Gear 7, guide wheel 10, guide wheel shaft 9, righting roller 6, righting roller shaft 15, mandrel 4, brake drum 21, knob shaft 13, handle 19, brake drum 21 consists of cover plate 12 and brake gear 11 Composed of two parts, the open gear cover 8 and the open gear 1 are fastened together by screws, and the outer curved tooth plate 2 is installed on the two wings of the butterfly jaw plate 3 . Each butterfly jaw plate 3 is fixedly connected with the mandrel 4 by a spline or other means, and each mandrel 4 has two journals up and down, which are respectively installed in the shaft holes provided by the open gear cover 8 and the open gear 1 and can be freely Rotate, the circle where the central axis of each shaft hole is located is concentric with the open gear (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com