Pipeline evacuating valve

A technology for emptying valves and pipes, applied in the directions of lift valves, valve details, valve devices, etc., can solve the problems that pipes cannot be emptied, affect the next water supply, cannot overcome spring pressure, etc., and achieve pipe material saving and simple structure. Reasonable, good emptying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

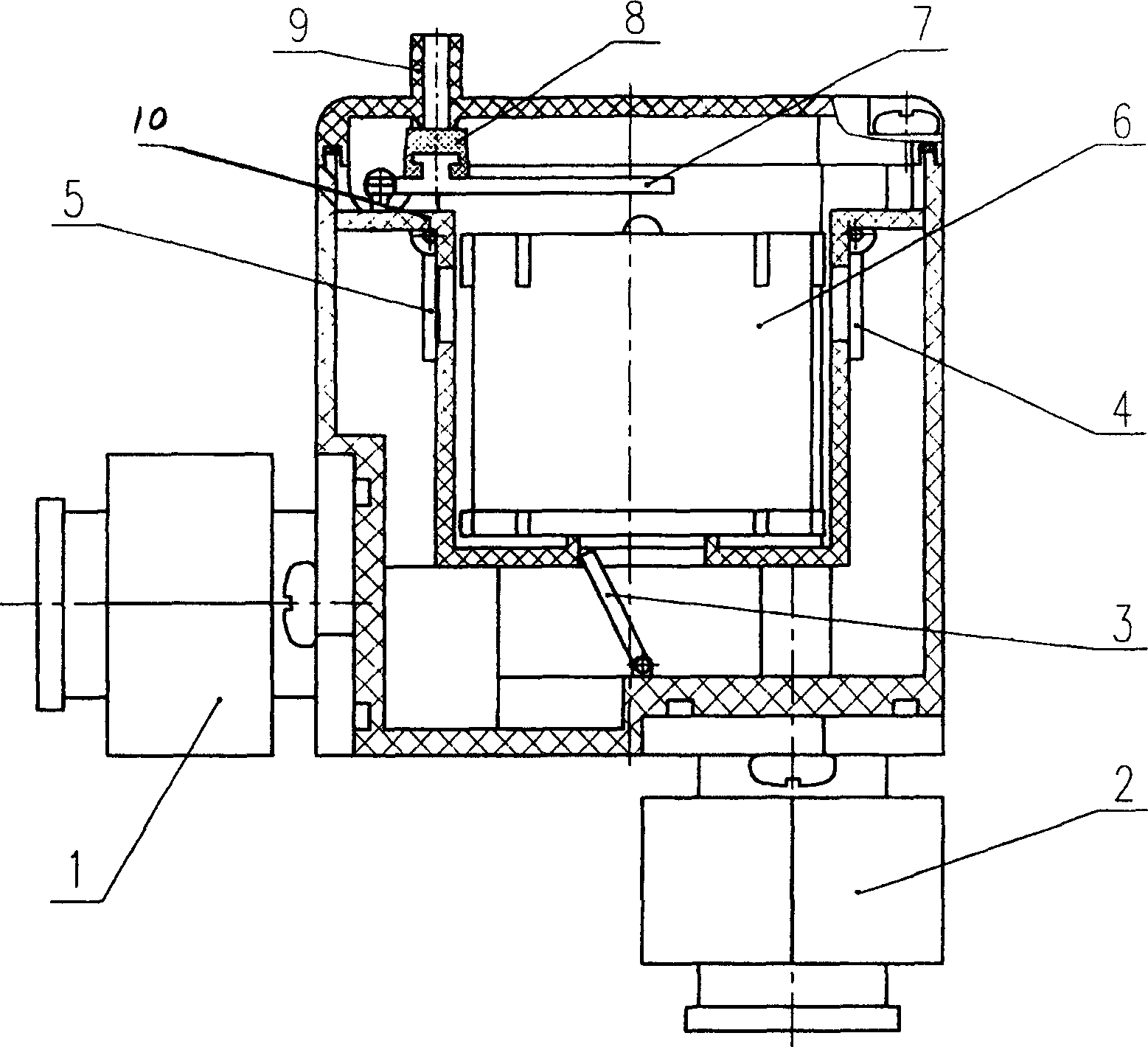

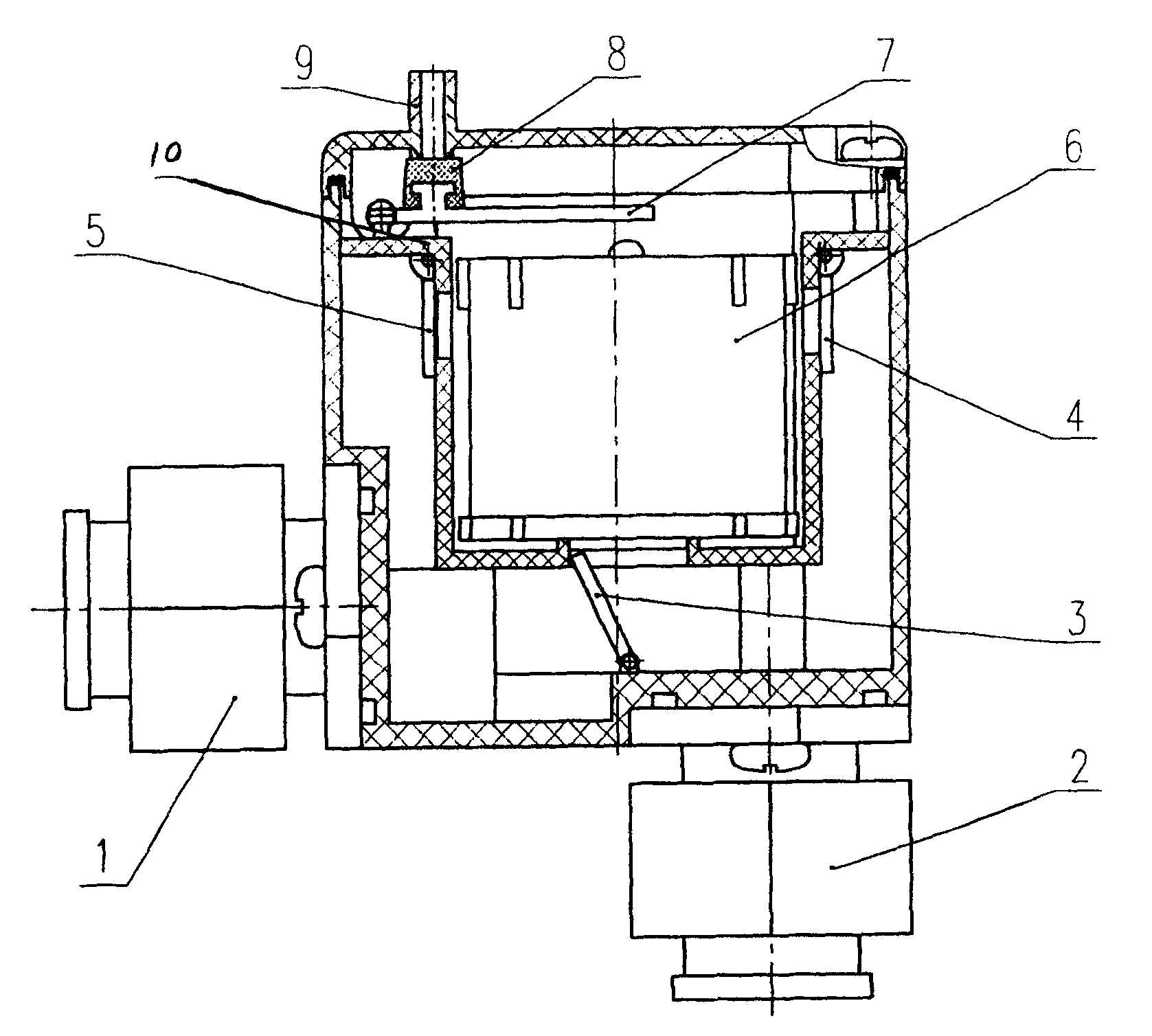

[0007] The pipeline emptying valve shown in the accompanying drawing is a valve body 10 with a water inlet 1 and a water outlet 2. The valve body 10 is provided with a two-way door 3 and a float 6. The left valve wall of the two-way door 3 is provided with a left single valve. To the door 5, the top valve wall is provided with an intake and exhaust pipe 9, and a lever 7 is also provided on the inner upper part of the valve body 10. The top of the float 6 is aligned with the movable end of the lever 7, and the fixed end of the lever 7 is hinged on the wall of the valve body 10. The sealing lining 8 that is contained on the lever 7 just in time covers the intake and exhaust pipe 9 ports when the lever 7 is jacked up, and opens the intake and exhaust pipe 9 ports when the lever 7 falls. Open a right one-way door 4 again on the valve wall on the right side of the two-way door 3 in the valve body 10. When the water is supplied, the water enters from the water inlet 1, the left one-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com