Power supply system based on bus/current collector

A technology of power supply system and bus bar, which is applied in the direction of power lines, rail joints, roads, etc., and can solve problems affecting the continuity of current guidance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

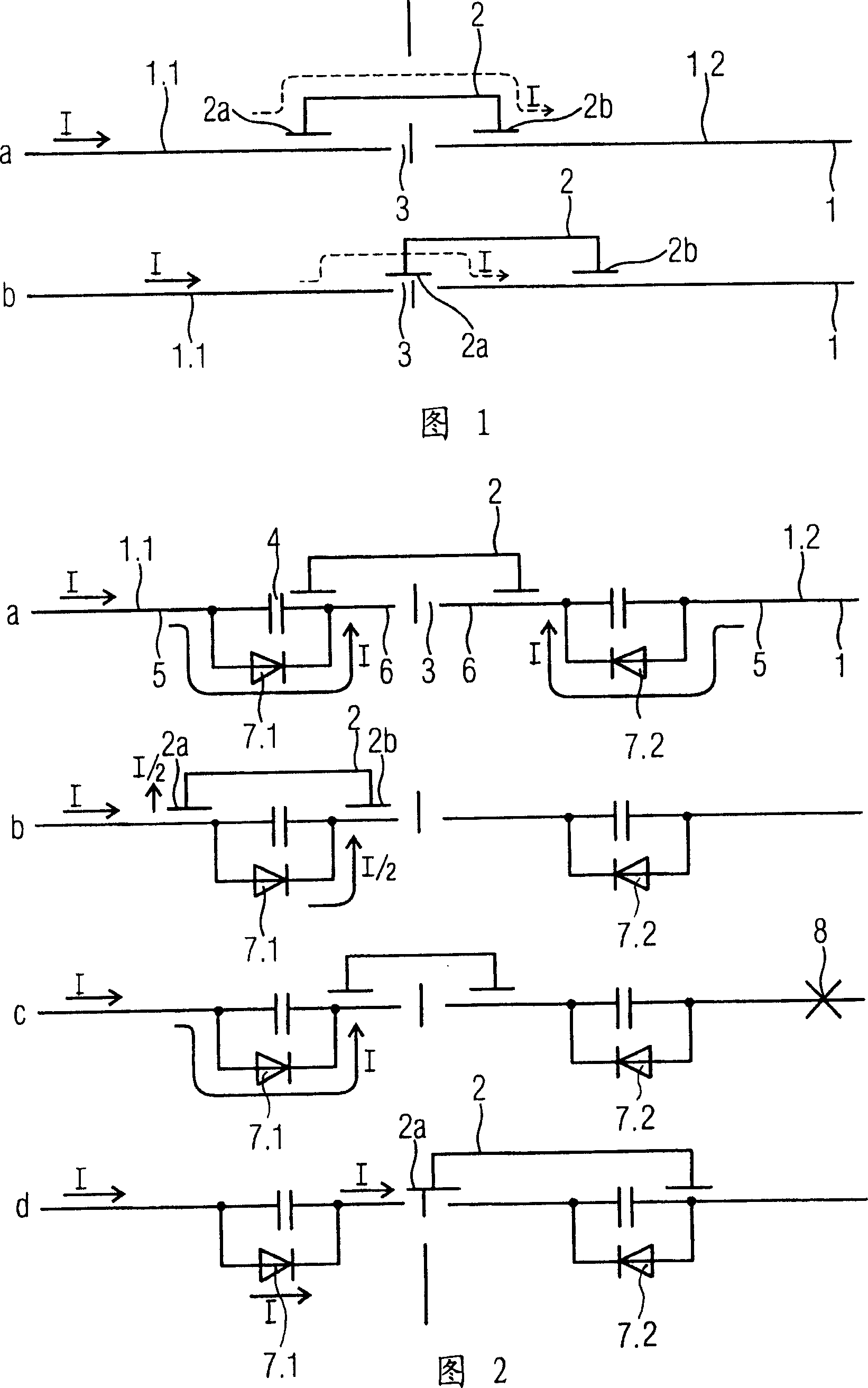

[0013] FIG. 1 shows a busbar 1 of conventional design for two different positions a and b of a current collector 2 which is connected to a power supply unit of a vehicle. The busbar 1 is subdivided into feeder segments, of which two segments 1.1 and 1.2 are partially shown. There is a separation point 3 between the feed sections 1.1 and 1.2. According to a in the figure, the current collector 2 with the contact points 2 a and 2 b bridges the separation point 3 . The contact points 2a and 2b may be sliding contact points. Obviously, in this position a, almost all the current I flows from the feeder segment 1.1 through the collector 2 to the subsequent feeder segment 1.2. This current is shown by dashed lines. In the position b, where the contact point 2 a of the current collector 2 is at the separation point 3 , the current I flows through this contact point 2 a. Such a current indicated by a dotted line is undesirable and has hitherto only been insufficiently suppressed by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com