Bushhammer

A chisel machine and frame technology, which is applied in the field of chisel machines, can solve problems such as the inability to fundamentally eliminate the hazards of concrete surface slurry, the difficulty in meeting the requirements for smooth concrete surface rough treatment, and the inability to guarantee the quality of building construction. Achieve the effect of good chiseling quality, lighten heavy manual labor, and strong randomness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

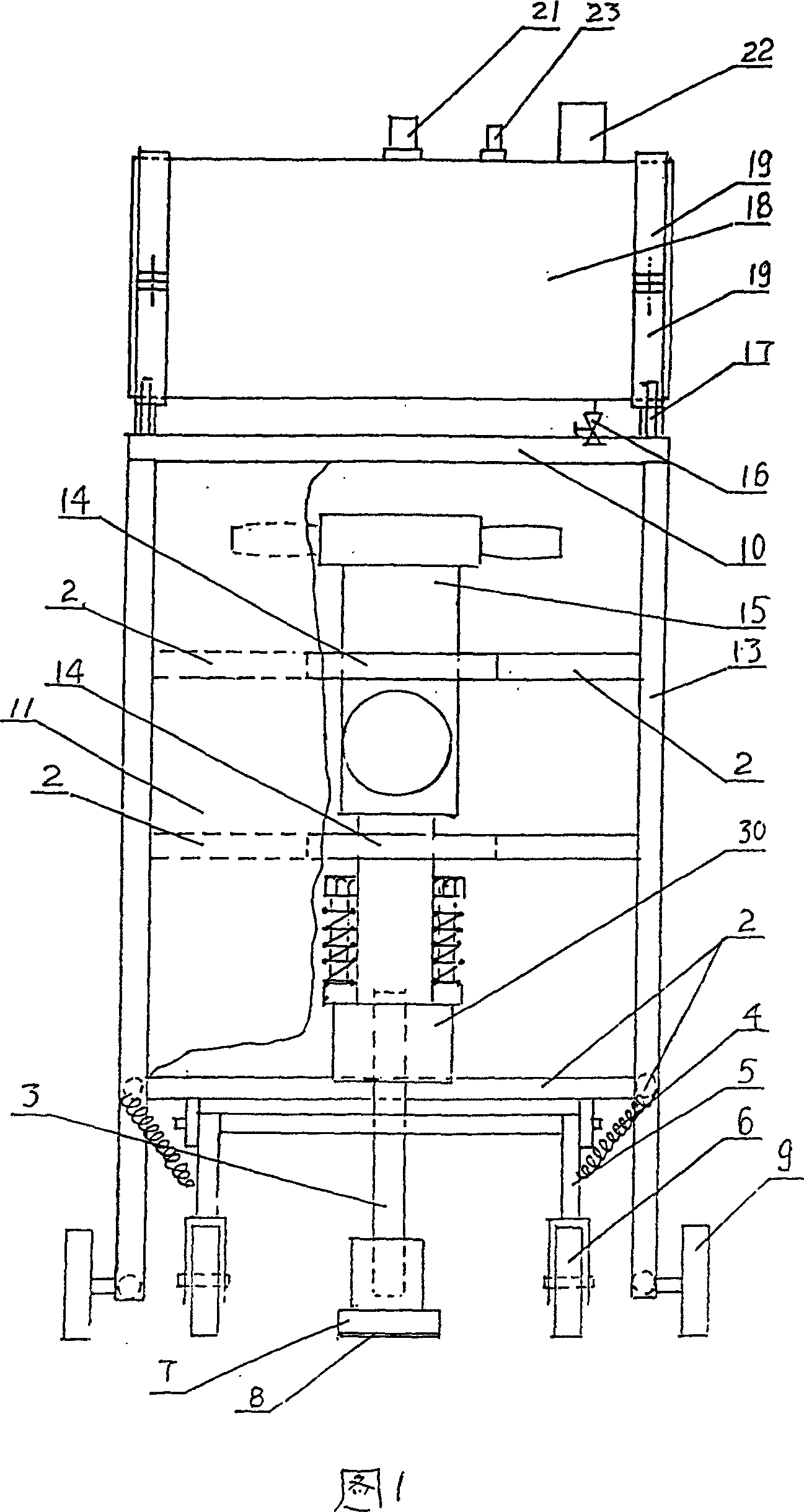

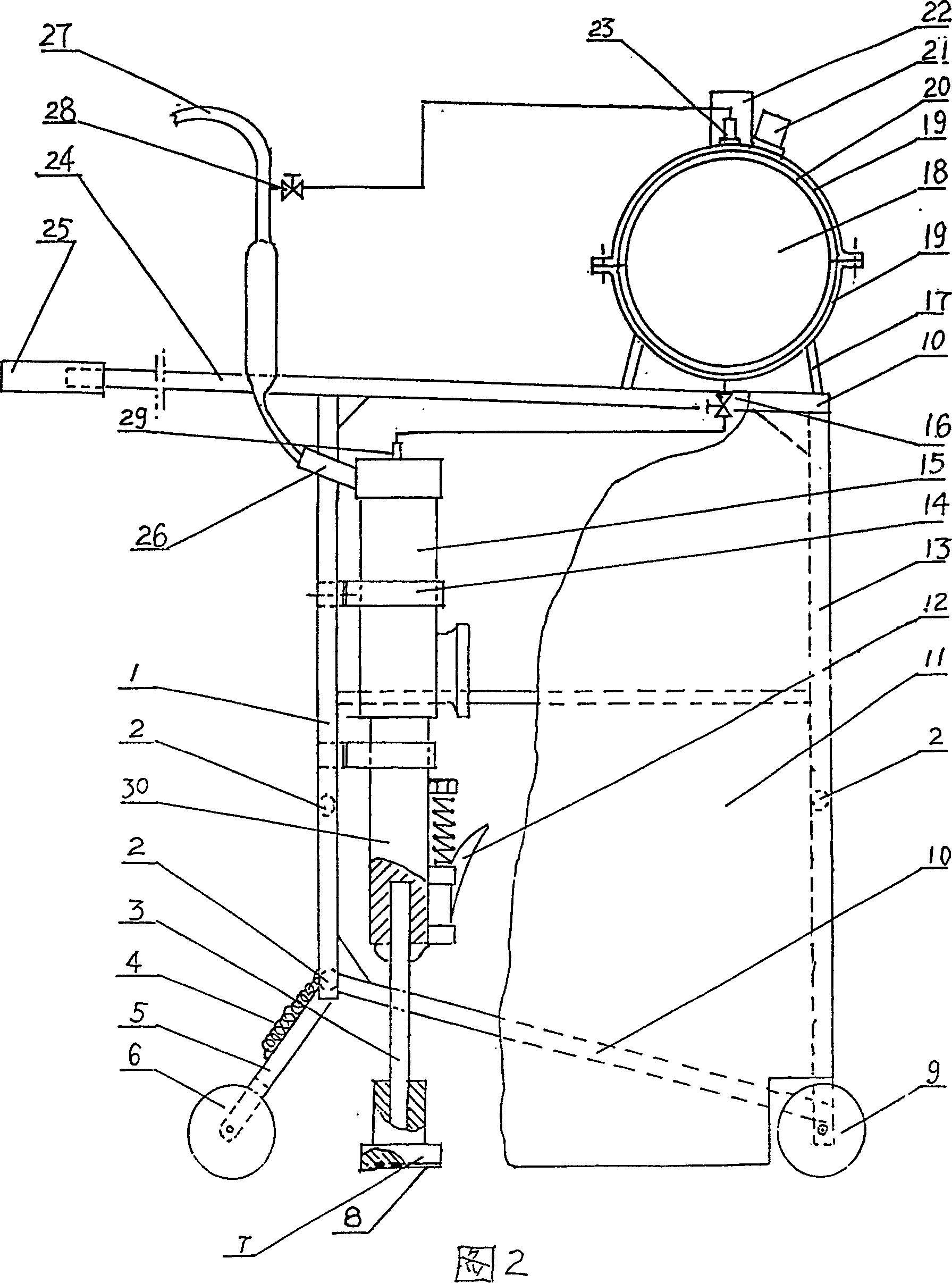

[0015] Shown in Fig. 1, 2 is one of embodiment of the present invention, and the upper and lower parts of its chisel head 7 are circular, and the cemented carbide grain block in the cemented carbide layer 8 is the chisel machine that strip shape is evenly distributed, Its structure includes: frame, dust screen curtain 11, pneumatic drill body 15, chisel head device, air pressure cooling water tank 18, hand-push damping handle 24, universal wheel 6 landing gear, front roller 9, consists of left, The front and rear poles 13,1, crossbeam 2, top and bottom beams 10 of the right are assembled to form a square frame, and the front, rear, left and right sides of the frame are connected with dust-proof screens 11 made of thin iron plates, The upper and lower clips 14 in the frame are fixed to the pneumatic drill body 15 on the rear side beam 2, the drill pipe connection sleeve 30 of the pneumatic drill body 15 faces downward and is perpendicular to the ground, and the drill pipe connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com