Small power spot welding power

A low-power, spot-welding technology, applied in output power conversion devices, electrical components, and AC power input to AC power output, etc. The circuit is complex and other problems, to achieve the effect of safe and reliable working state, light weight and small size of the power supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

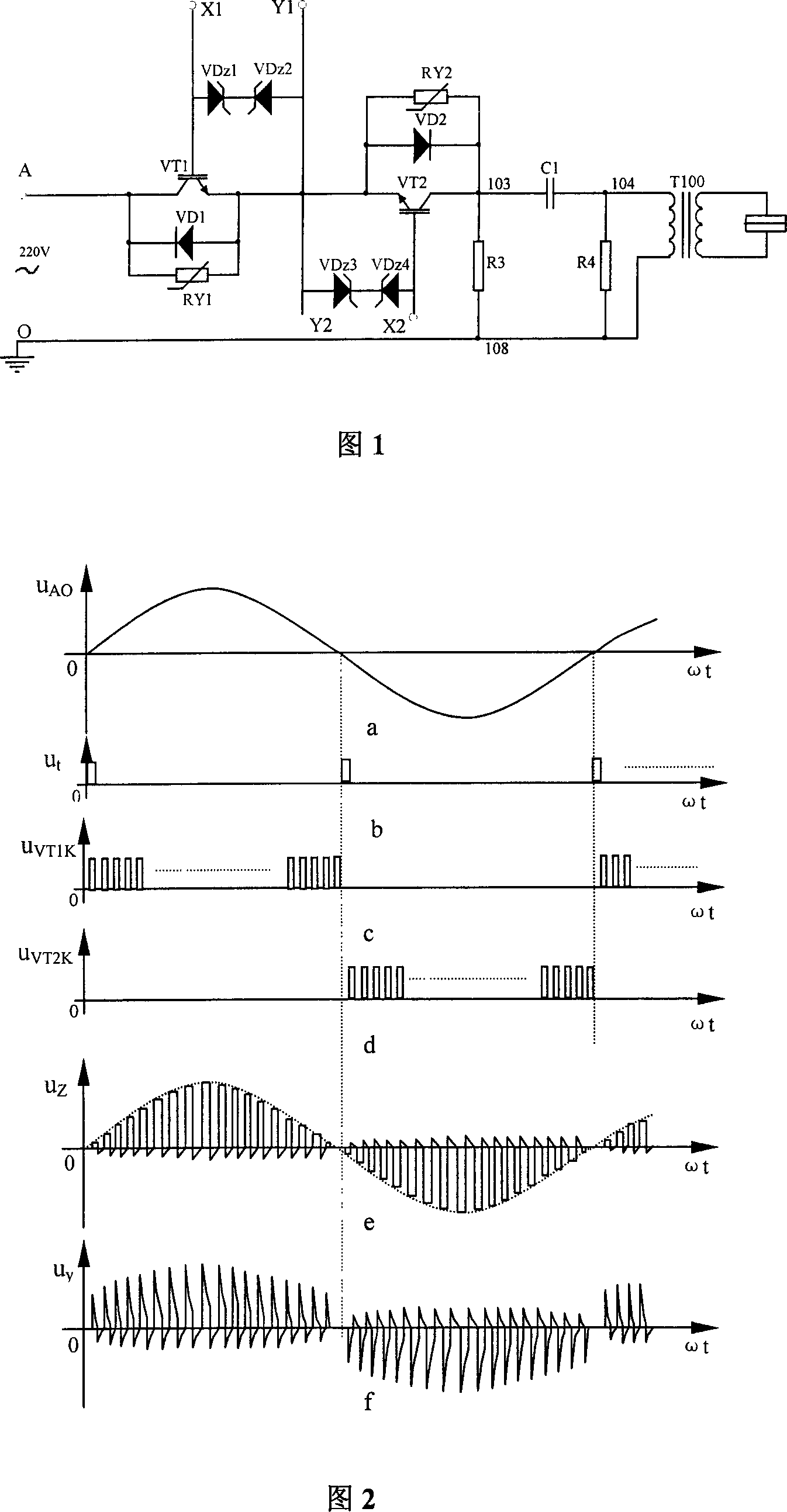

[0010] 1, the present invention uses a high-power insulated gate bipolar transistor (hereinafter referred to as IGBT tube) as a switching device, adopts AC / AC conversion technology to chop the input AC power at a certain frequency, so as to directly obtain the AC power of the required frequency. welding.

[0011] The circuit consists of IGBT tube VT1, IGBT tube VT2, capacitor C1, resistor R3, resistor R4, diode VD1, diode VD2, Zener diode VDz1, Zener diode VDz2, Zener diode VDz3, Zener diode VDz4, Varistor RY1 It is composed of varistor RY2 and welding transformer T100. After the IGBT tube VT1 is electrically connected to the emitter of the IGBT tube VT2, the collector of the IGBT tube VT1 is connected to the circuit input terminal A, the collector of the IGBT tube VT2 is electrically connected to the input terminal of the filter, and the output terminal of the filter is connected to the welding transformer T100. When connected electrically, the filter is a common RC filter; the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com