Support portion structure of pendant for vehicle

A technology for supporting parts and supporting parts, which is applied to the lower structure, upper structure, vehicle parts, etc., can solve the problems of increased cost, large number of parts, and many assembly man-hours, and achieves accurate connection operation and good workability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

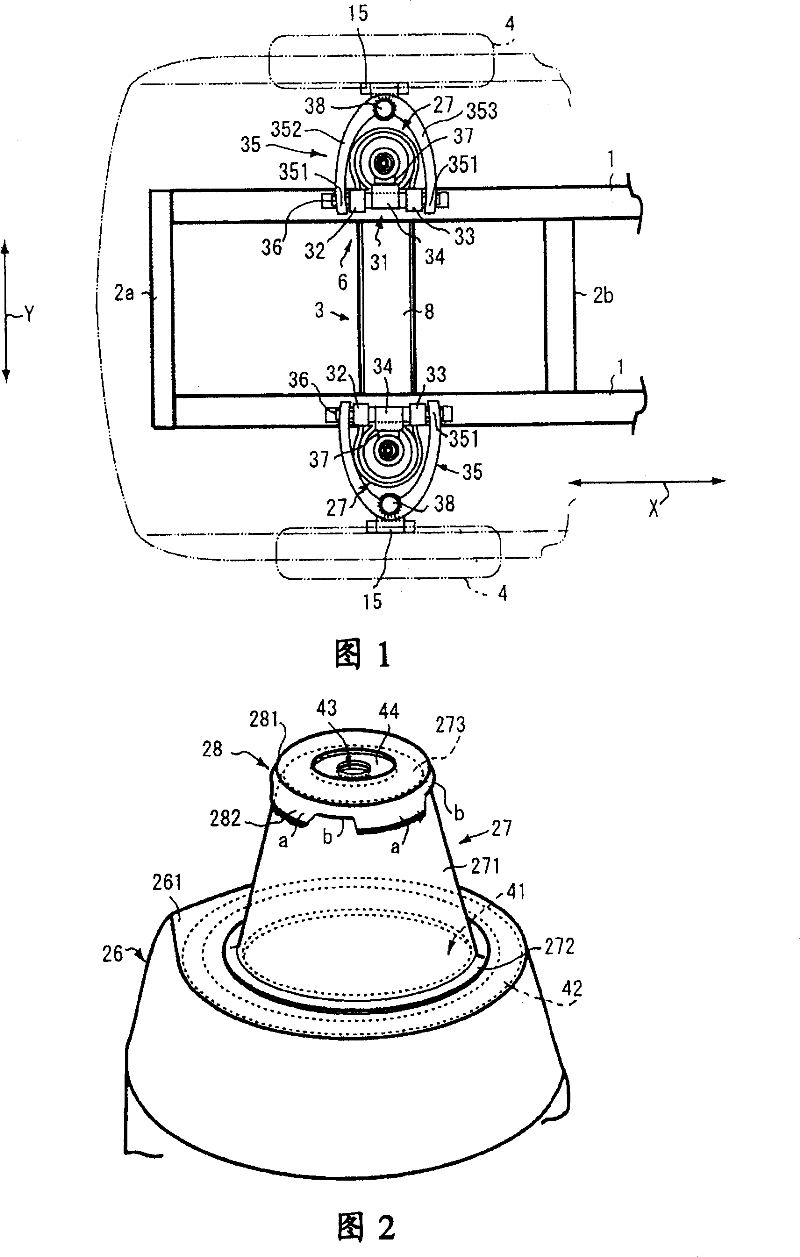

[0024] FIG. 1 shows a front portion of a vehicle body of a commercial vehicle to which a suspension support structure for a vehicle according to an embodiment of the present invention is applied.

[0025] The front part of the vehicle body includes a pair of left and right side beams 1 extending in the front-rear direction X, and a plurality of cross beams 2a, 2b, 3 arranged facing the vehicle width direction Y and connecting the side beams 1 on both sides.

[0026] Here, the beams are sequentially arranged rearward through the front beam 2a at the front end, the suspension beam 3 supporting the suspension components, the middle beam 2b, etc., and are respectively connected between the left and right side beams 1, thereby strengthening the strength of the front part of the vehicle body. .

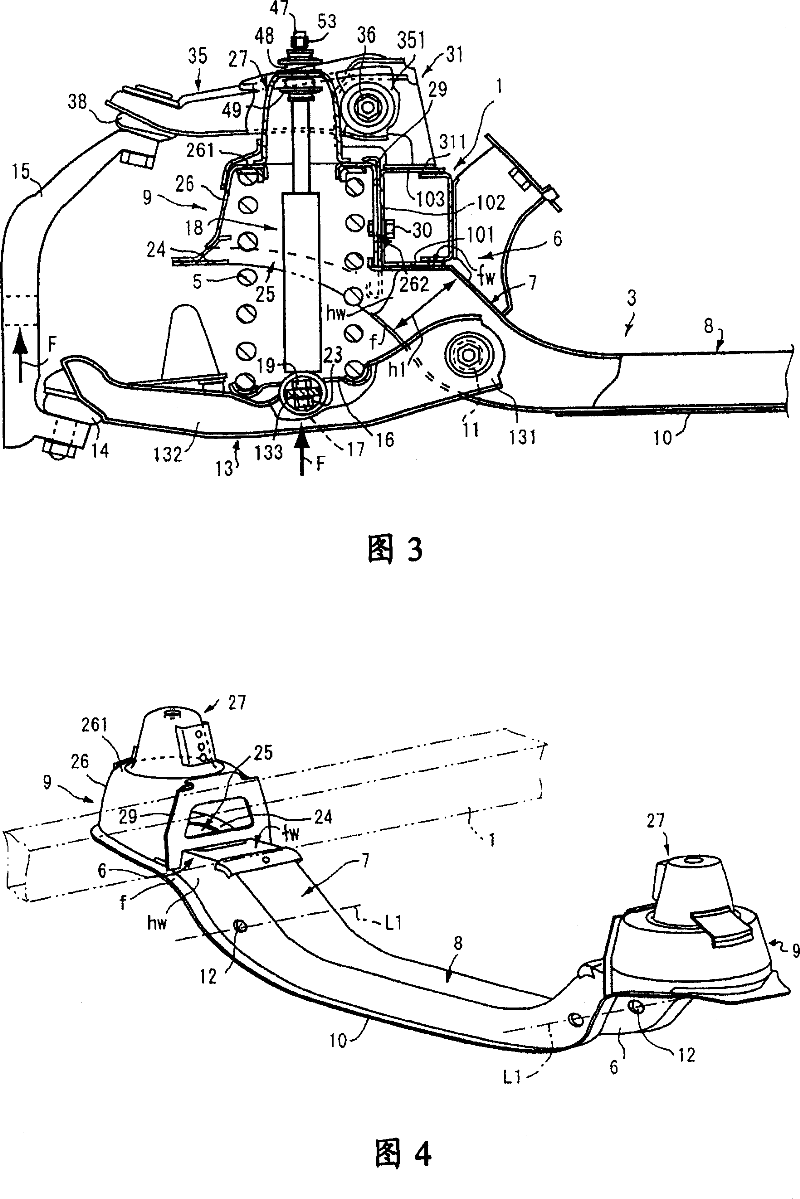

[0027] As shown in Figures 3 and 4, the suspension crossbeam 3 as a suspension support component includes: a pair of left and right connecting parts 6, which are connected and fixed on a pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com