Compensable recovering apparatus for used zip-top cans and beverage bottles

A technology of recycling device and beverage bottle, applied in the field of detection and classification device, can solve the problems of living environment pollution, mental pollution, increasing the workload of cans and beverage bottles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to further illustrate the present invention, below in conjunction with embodiment is described in more detail.

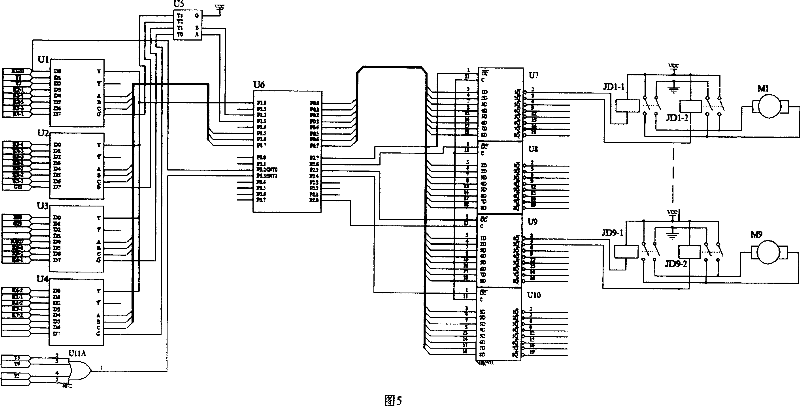

[0028] The invention is used to recycle used beverage bottles and aluminum cans, and the key lies in object recognition.

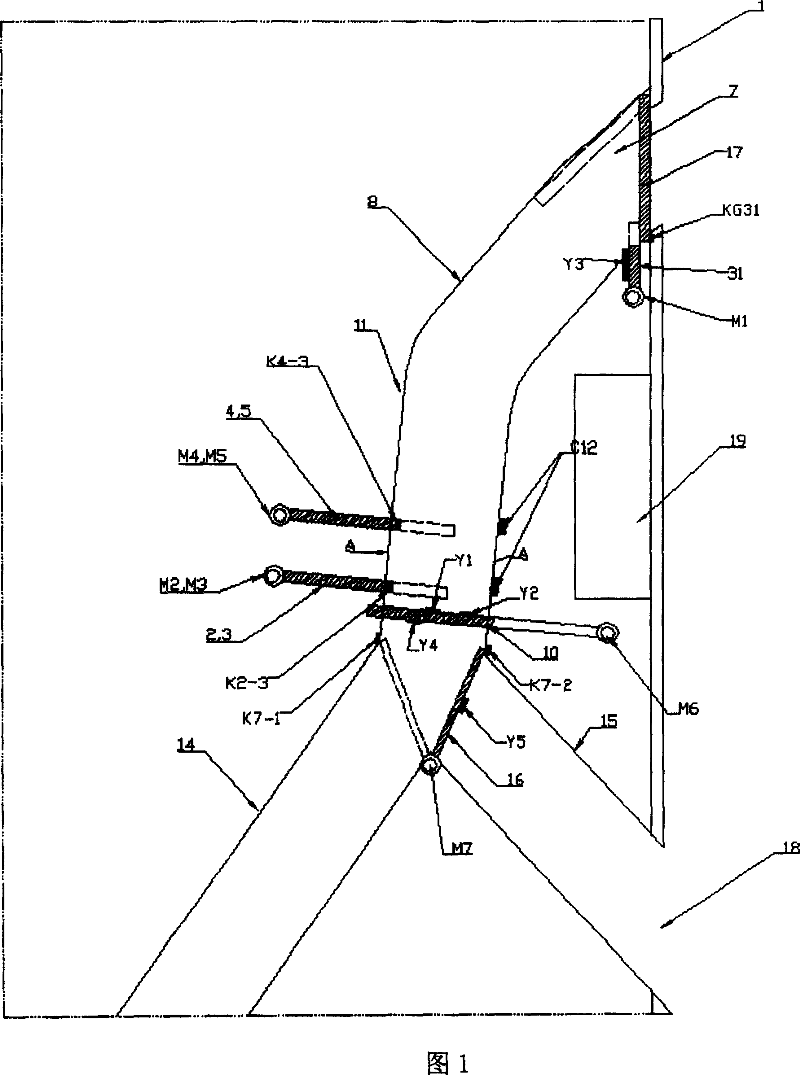

[0029] Fig. 1 is a schematic diagram of an embodiment of the present invention, above the front part of the box body 1, there is a bottle can entrance 2, an entrance flap 17 is provided in the entrance, and a flap contact switch KG31 and an electric door latch 31 are arranged on the inner side under the door .

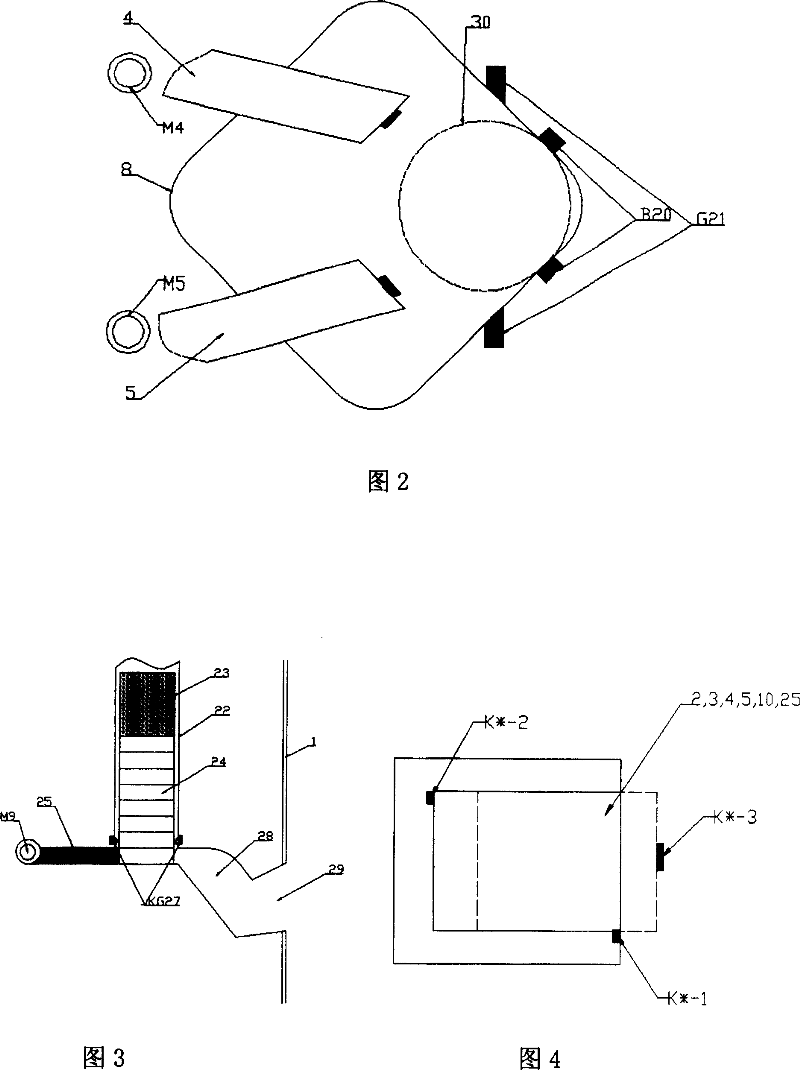

[0030] The bottle inlet 2 is directly connected to a detection area 11 through the pipeline 3, and two pipelines are connected under the detection area 11, one is a sieve pipeline 14, and the other is a waste pipeline 15, and a sieve baffle 16 is arranged at the branch, hinged It is located below the baffle to connect with the intersection of the sieving pipeline and the waste pipeline, and a detection baffle 10 is arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com