Stator core for linear motor

A linear motor and stator core technology, applied in the field of movers, can solve the problems of insufficient efficiency and complexity of the stator core, achieve high filling factor and reduce negative effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

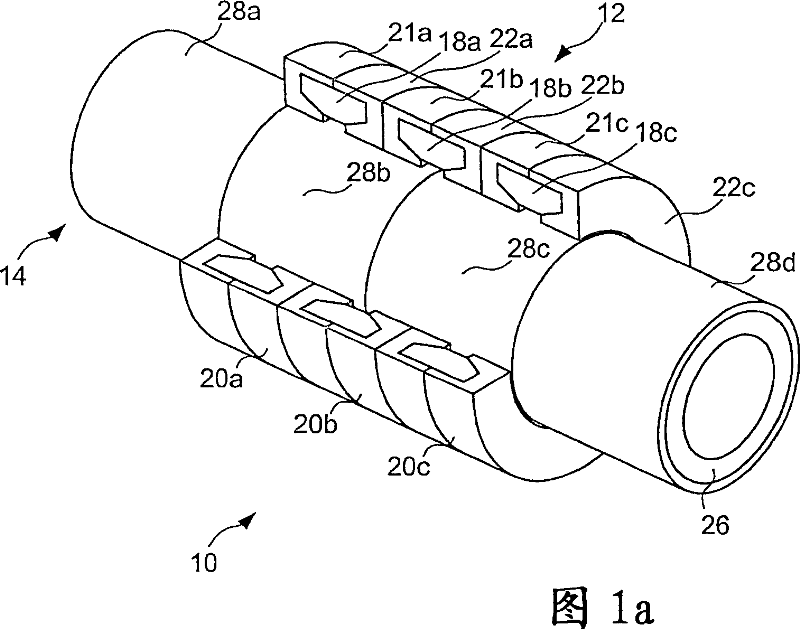

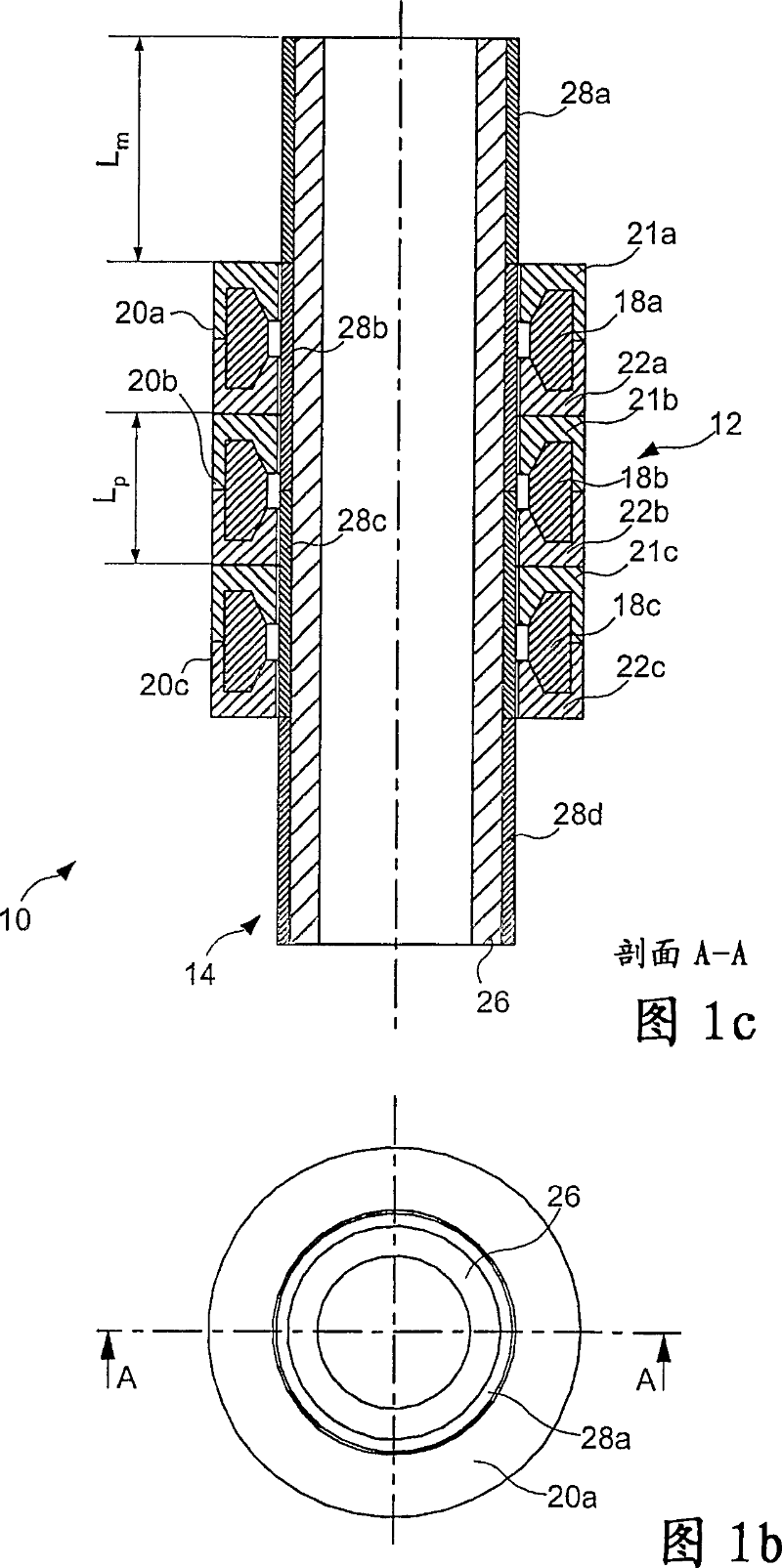

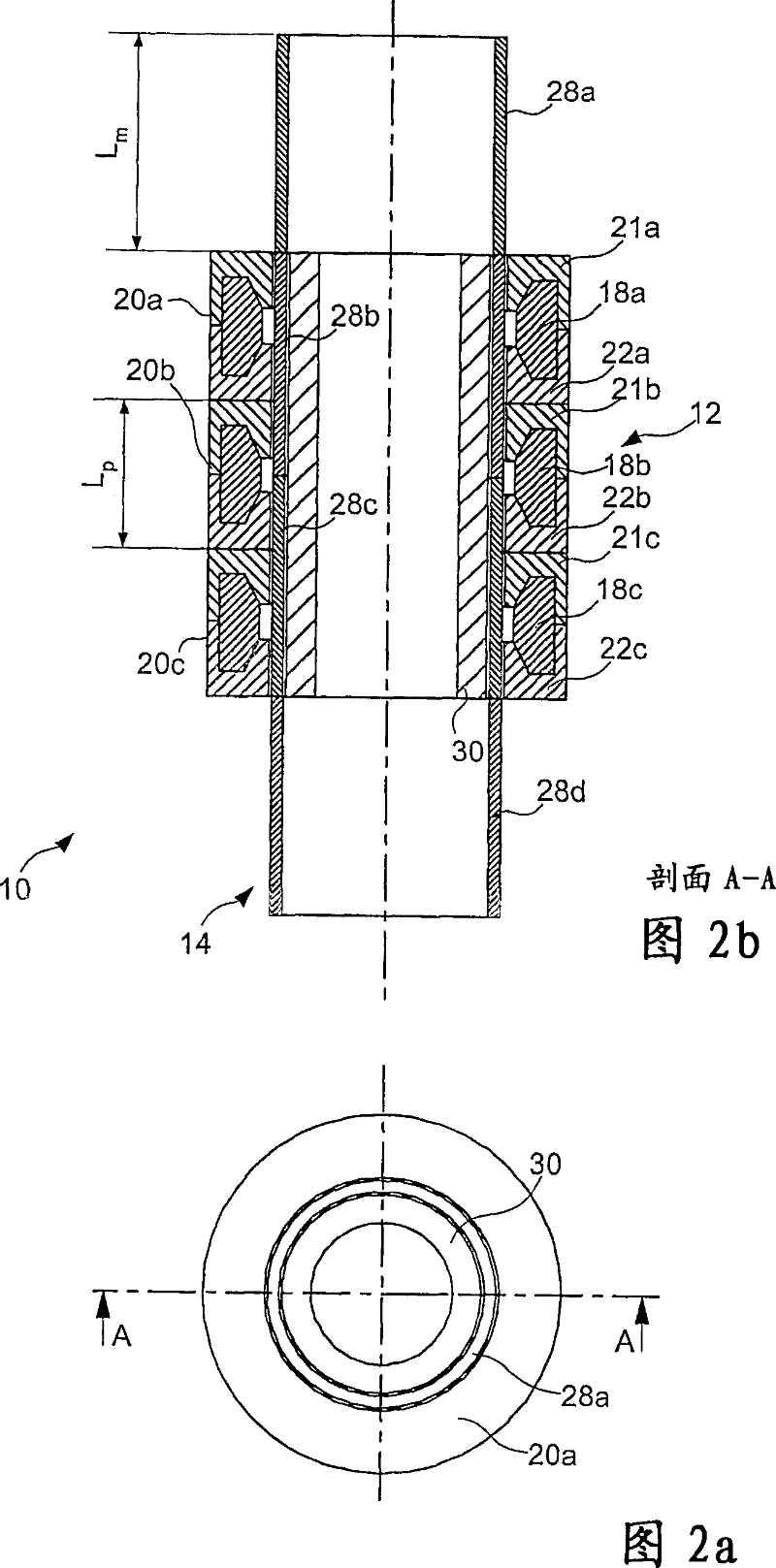

[0065] In Figs. 1a-c, a schematic diagram of a linear motor according to an embodiment is shown. The linear motor 10 includes a stator 12 and a mover 14 . Usually, the stator is stationary and drives the mover axially, however, it is also possible to make the mover stationary and let the stator drive itself axially. Thus, in the context of the present invention, axial is the direction of movement of either the mover or the stator, depending on which of the two will move relative to the other.

[0066] The stator includes at least one coil 18a-c and at least one stator core 20a-c. The stator coils can be a single winding, i.e. a wire wound into a coil and connected to a power supply unit not shown, or a distributed winding, i.e. each stator coil includes a different output port connected to the power supply unit and thus can transmit the Line(s) of current of different electrical characteristics. Those skilled in the art of electric motors know many different types of power ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com