Method for manufacturing a battery, battery, and motor vehicle

A technology for motor vehicles and batteries, which is applied in the field of manufacturing batteries and can solve problems such as high voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

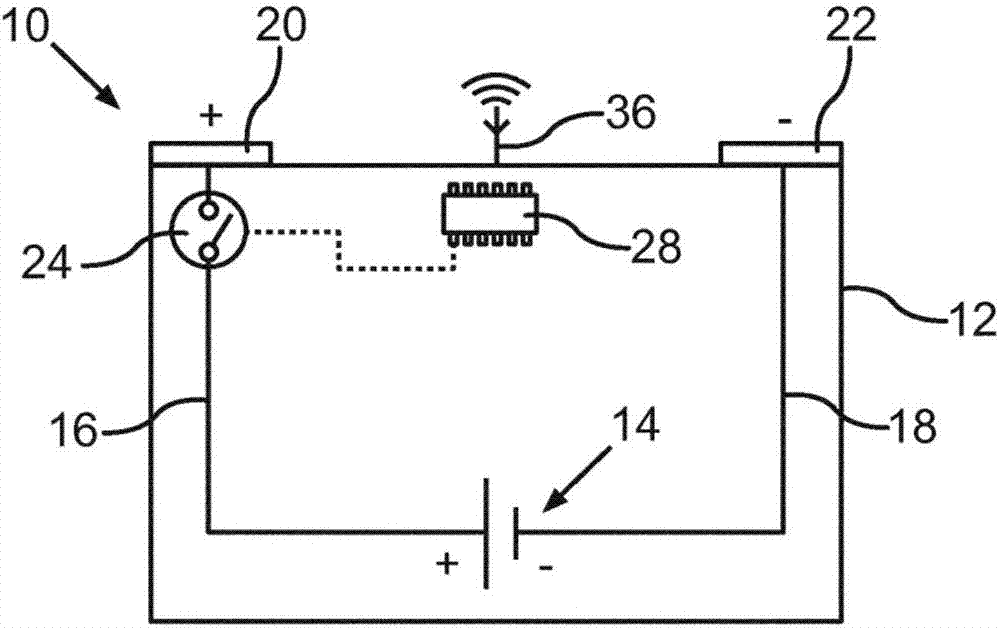

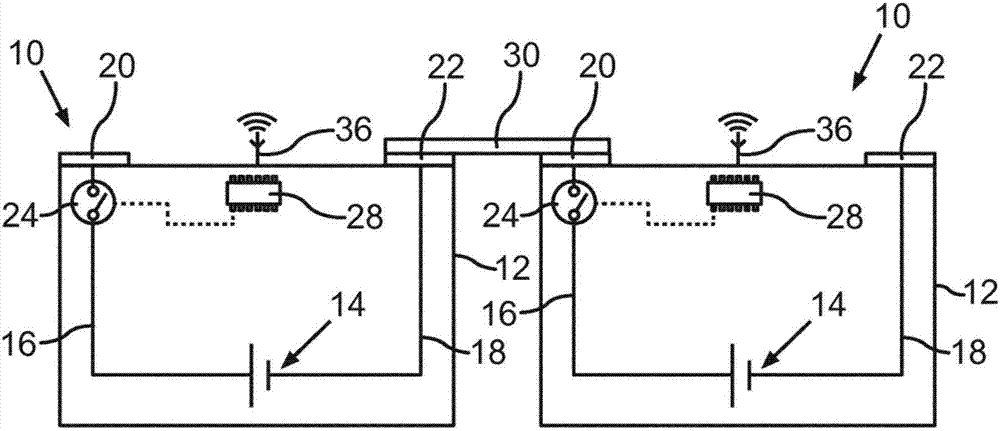

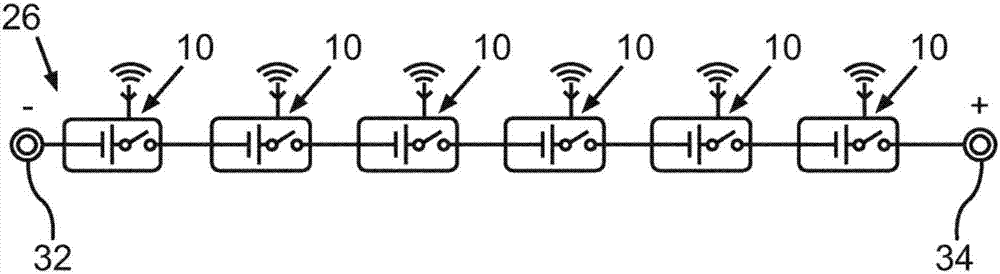

[0039] exist figure 1 A battery cell 10 is schematically shown in image 3 In the same schematically shown battery 26. For this purpose, the battery cells 10 can be designed, for example, as lithium-ion battery cells. In a battery 26 , which is used, for example, as a traction battery for a motor vehicle, a plurality of such battery cells 10 are usually electrically connected in series and / or in parallel in order to provide a correspondingly high voltage and high current.

[0040] When such battery cells 10 are connected in series, very high voltages of the battery 26 , even voltages of several hundred volts, can occur overall, for example because a plurality of battery modules each containing a plurality of battery cells are electrically conductively connected to one another. 10. However, such high voltages and the occurrence of short circuits or arcs can be dangerous for persons. This risk is avoided or reduced, for example, during the manufacture of the battery 26 . Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com