One-way rotary multi air-exhaust angle cock door

A technology of unidirectional rotation and corner cocking, which is applied to railway car body parts, transportation and packaging, pneumatic brakes, etc., can solve problems such as waste of funds, resources, pressure out of control, and prevention of man-made sabotage, so as to reduce workload and guarantee The effect of driving safety and reducing material consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

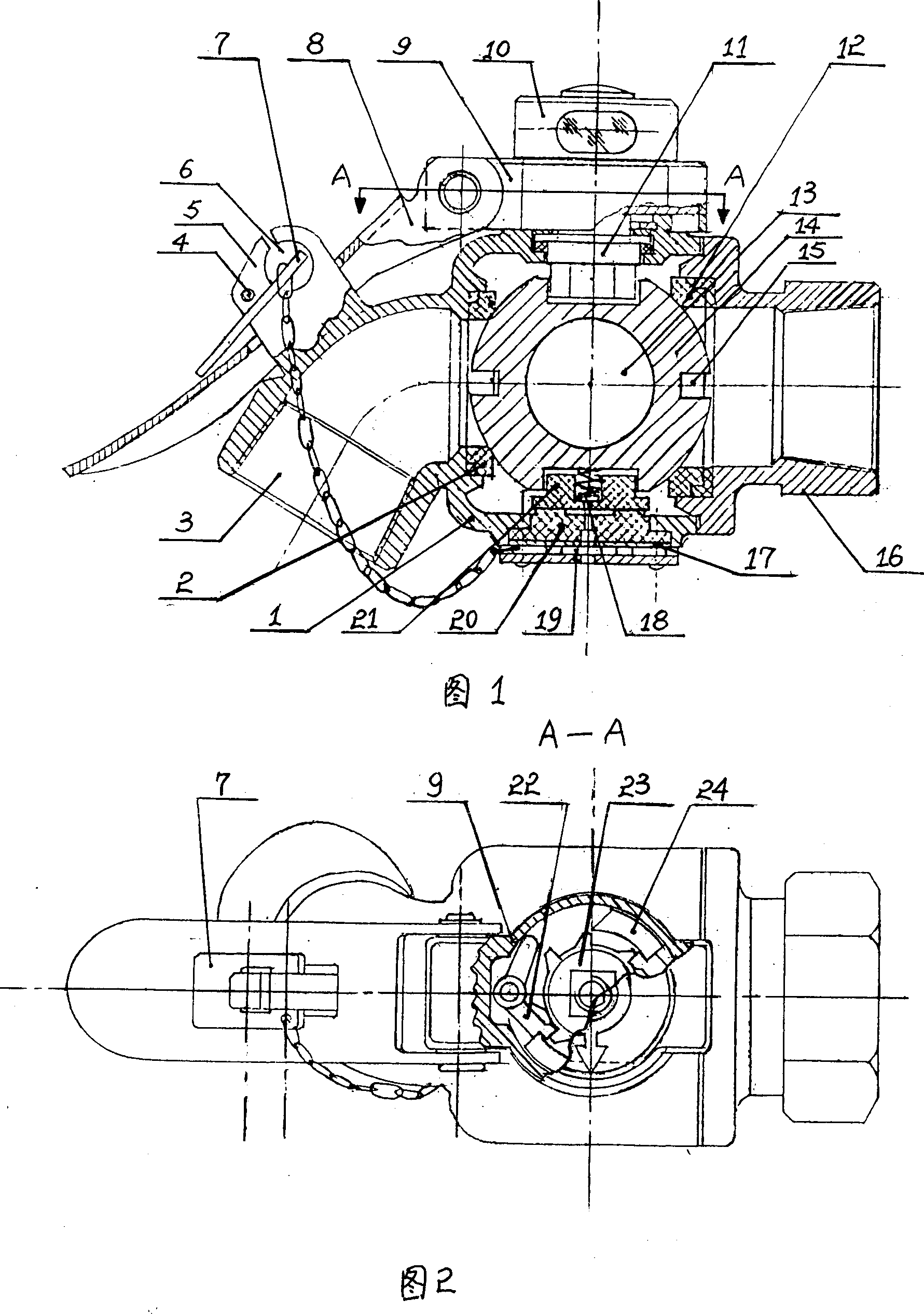

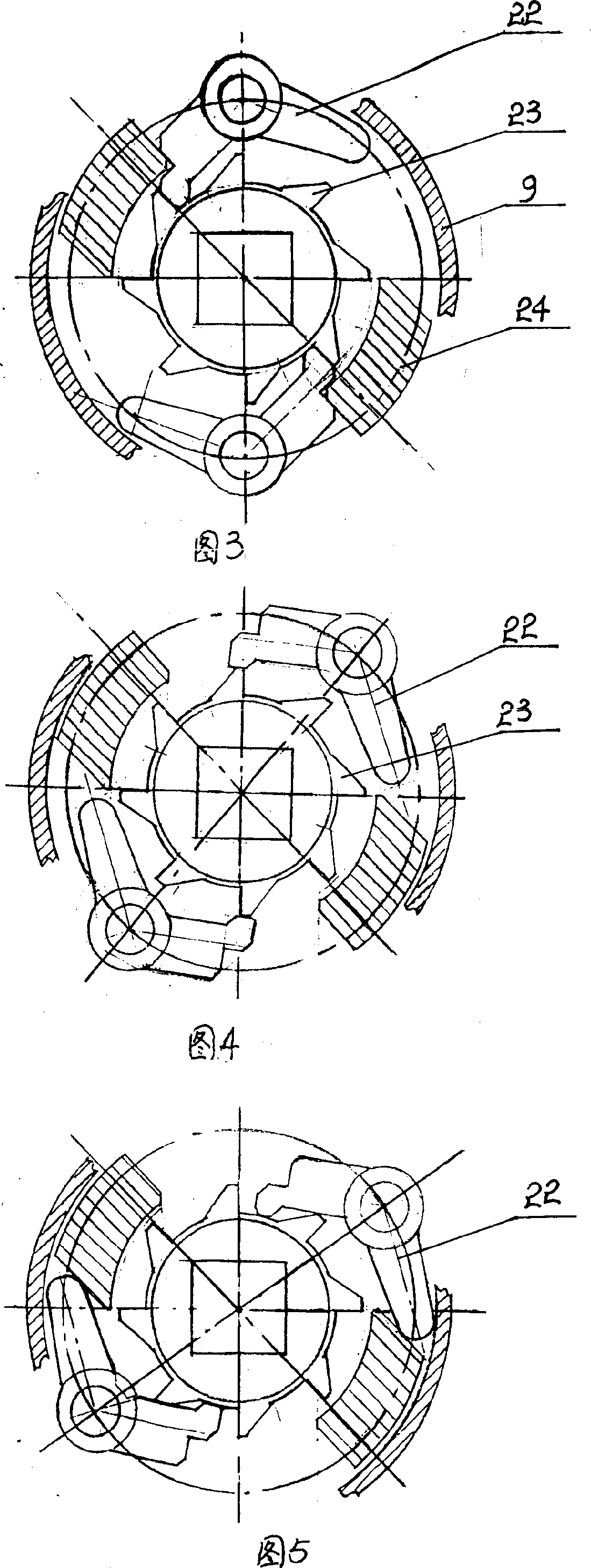

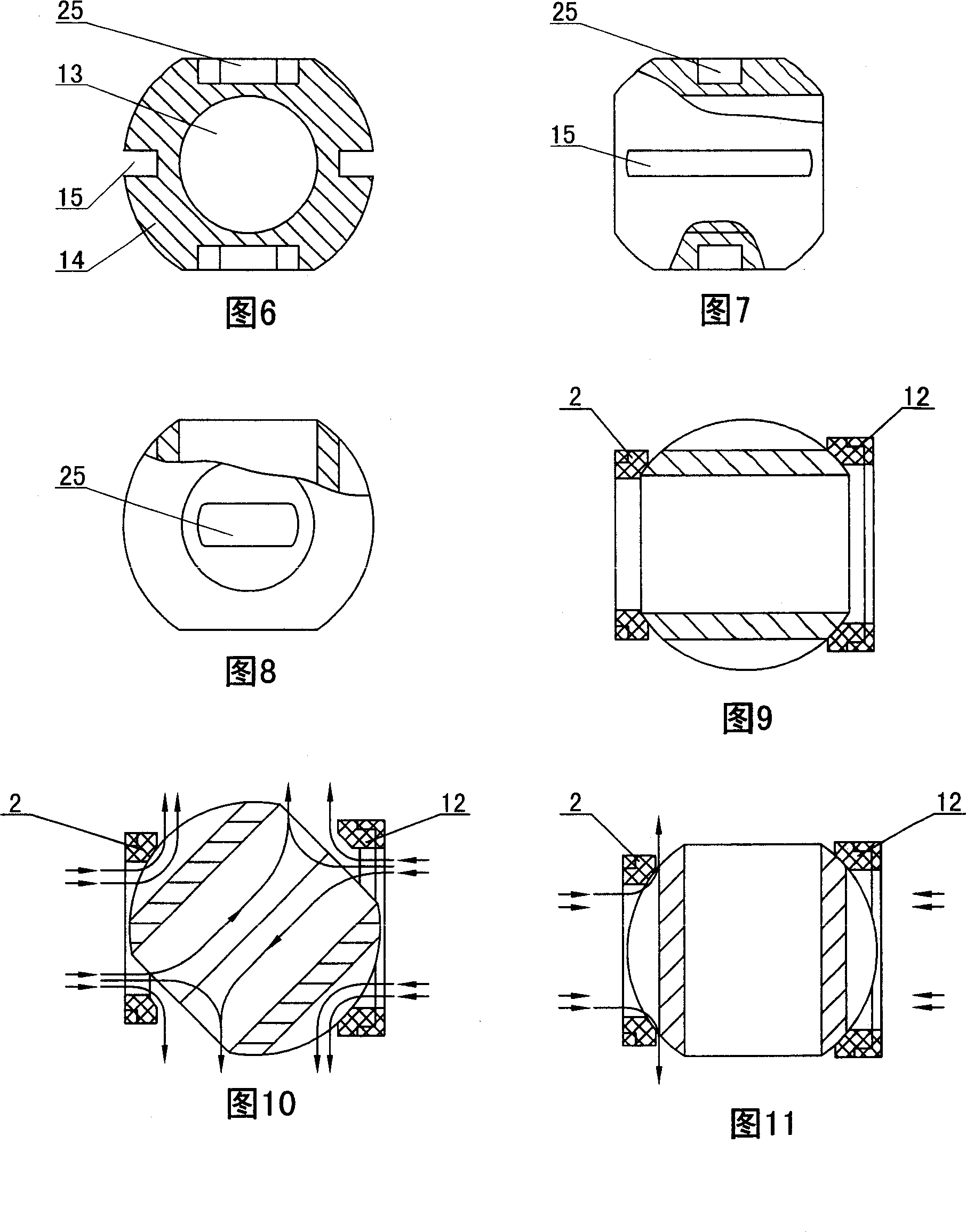

[0041] 1 Plug door body 2 Small sealing ring 3 Hose connector 4 Open pin hole 5 Locking nose 6 Stop pin jack 7 Stop pin 8 Active handle 9 Handle seat 10 Top gland 11 Rotating shaft 12 Large seal ring 13 Main channel 14 Plug core sphere 15 Exhaust groove 16 Main pipe joint 17 Regulating exhaust liner 18 Spring 19 Exhaust protective cover 20 Regulating exhaust seat 21 Regulating exhaust swivel 22 Pawl 23 Ratchet wheel 24 Limiting block 25 Slot 26 Toggle block 27 Spring hole 28 Main exhaust hole 29 Secondary exhaust hole 30 Micro exhaust hole 31 Concave platform 32 Small exhaust hole 33 Large exhaust hole 34 Boss 35 Scattering exhaust hole 36 Scattering exhaust channel 37 Convex ribs

[0042] The flexible handle 8 is hinged on the shell of the handle seat 9, which can be lifted, pushed and pulled, and can be tilted vertically upward when subjected to external force; the flexible handle 8 is provided with a socket corresponding to the locking nose 5, which can be dropped and inserted...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com