Parallelism adaptive pressure head of diffusion welding machine and adaptive regulation method of pressure head

A parallelism, diffusion welding technology, applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve the problems of low welding qualification rate and difficult to adjust parallelism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

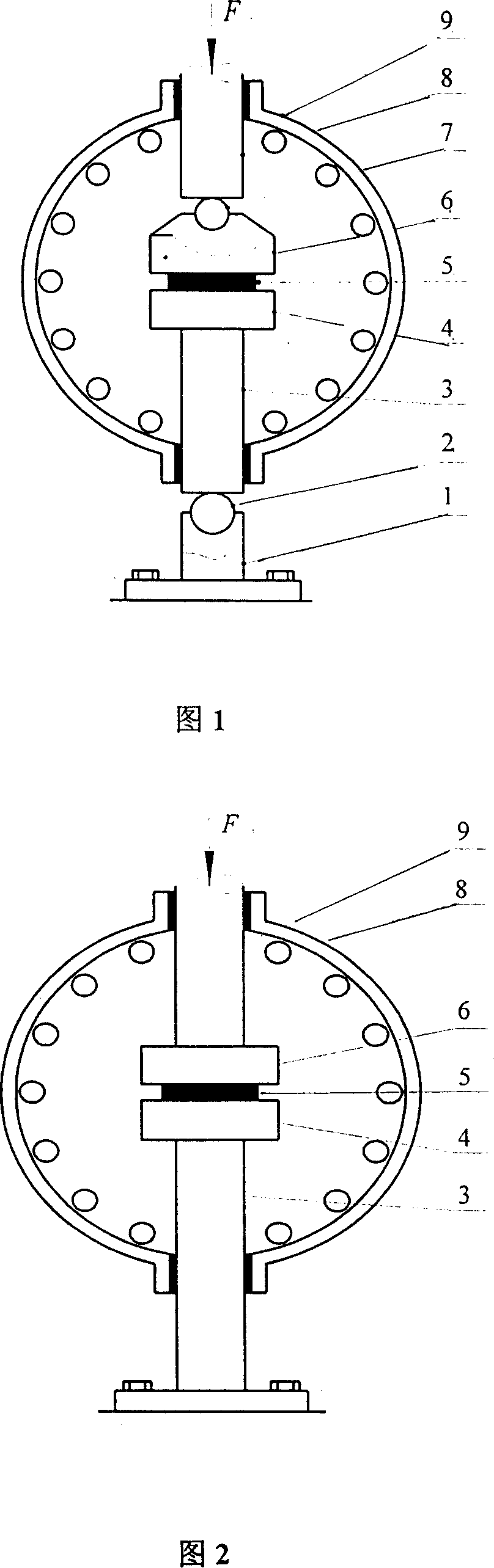

[0018] Embodiment 1: With reference to Fig. 1. The parallelism adaptive pressure head of the diffusion welding machine of the present invention includes a lower pressure rod 3, a lower pressure head 4, an upper pressure head 6 and an upper pressure rod 8, and also includes a base 1, steel balls 2 and ceramic balls 7. 1. The top of the cylinder has a hemispherical concave surface matching with the steel ball 2. The steel ball 2 is placed in the hemispherical concave surface on the top of the cylinder of the base 1. The lower end of the lower pressure rod 3 is ground and connected with the lower pressure head 4. The pressure rod hole below the furnace 9 is positioned and placed on the top of the steel ball 2; a boss is designed on the top of the upper pressure head 6, and a hemispherical concave surface matched with the ceramic ball 7 is arranged on the convex platform, and the ceramic ball 7 is placed in the hemispherical concave surface. The lower end of the upper pressing rod...

Embodiment 2

[0021] Embodiment 2: The parallelism self-adaptive pressure head structure of the diffusion welding machine is the same as the embodiment 1, the diameter of the base 1 cylinder is 120 mm, and the radius of the hemispherical concave surface at the top is 40 mm. The surface of the steel ball 2 is nitrided and hardened, and the surface of the steel ball 2 is in free contact with the lower end surface of the lower pressing rod 3; the radius of the steel ball 2 is 40mm. The radius of the hemispherical concave surface on the top boss of the upper pressing head 6 is 15mm, and the surface of the ceramic ball 7 is in free contact with the lower end of the upper pressing rod 8; the radius of the ceramic ball 7 is 15mm.

Embodiment 3

[0022] Embodiment 3: The adaptive adjustment method of the parallelism adaptive pressure head of the diffusion welding machine is the following steps:

[0023] (1) Embedding the steel ball 2 on the base 1, after fixing the lower pressure head 4 and the lower pressure rod 3, place the lower end plane of the lower pressure rod 3 on the top of the steel ball 2;

[0024] (2) Embedding a ceramic ball 7 on the upper end surface of the upper pressing head 6;

[0025] (3) When welding each time, the workpiece 5 is placed on the lower indenter 4, the upper indenter 6 is placed on the workpiece 5, and the position is adjusted;

[0026] (4) Move the upper pressing rod 8 to the top of the ceramic ball 7 on the upper end surface of the upper pressing head 6, apply welding pressure, make the upper and lower pressing heads fit the upper and lower surfaces of the workpiece, and complete the self-adaptive adjustment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com