Sewage water denitrification handling method

A treatment method and sewage technology, which is applied in the field of biological denitrification treatment of sewage, can solve the problems of difficult nitrification reaction, increased energy consumption, and increased floor area, so as to achieve high biochemical reaction rate, avoid activity inhibition, and occupy an area The effect of less area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] The water quality of a public toilet septic tank is as follows:

[0048] project

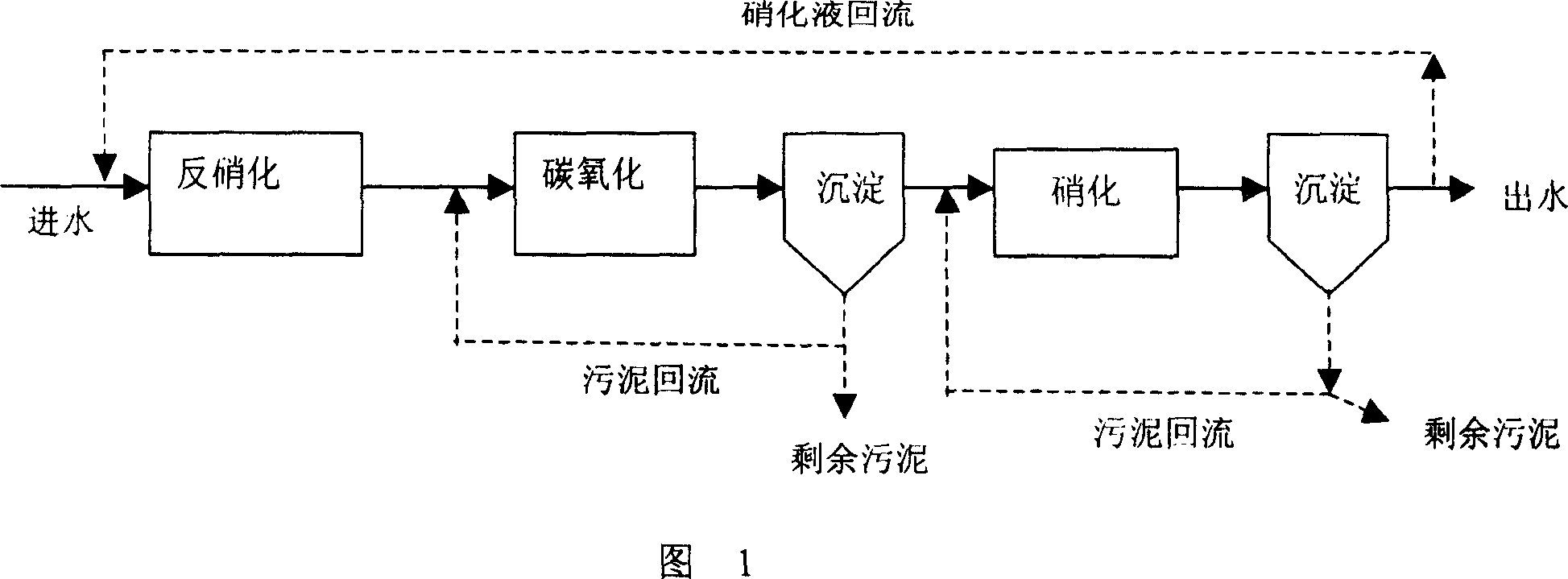

[0049] Carry out as shown in accompanying drawing 1, be 2 hours in denitrification tank hydraulic retention time, be 6 hours in carbon oxidation tank hydraulic retention time, be 3 hours in nitrification tank hydraulic retention time, the first settling tank flows back into the carbon oxidation tank The reflux ratio is 75%, the reflux ratio of the second sedimentation tank back into the denitrification tank is 150%, the residence time of the first sedimentation tank is 2 hours, and the residence time of the second sedimentation tank is 3 hours. The carbon oxidation tank is suspended activated sludge, the sludge concentration is 4g / L, the sludge age is 4 days, and the water temperature is 18°C. This method can make COD, BOD 5 , NH 3 -N removal rate is above 95%. The treated water can be used as non-contact reuse water after disinfection, or discharged after further treatment. ...

Embodiment 2

[0051] The water quality of a septic tank sewage is as follows:

[0052] project

[0053] Carry out as shown in accompanying drawing 1, be 3 hours in denitrification tank hydraulic retention time, be 10 hours in carbon oxidation tank hydraulic retention time, be 6 hours in nitrification tank hydraulic retention time, the first settling tank flows back into carbon oxidation tank The reflux ratio is 100%, the reflux ratio of the second sedimentation tank back into the denitrification tank is 300%, the residence time of the first sedimentation tank is 3 hours, and the residence time of the second sedimentation tank is 4 hours. Put suspended activated sludge in the carbon oxidation tank, the sludge concentration is 4g / L, the sludge age is 3 days, and the water temperature is 20°C; the sludge concentration in the nitrification tank is 5g / L, the sludge age is 30 days, and the water temperature is 20°C ℃. This method can make COD, BOD 5 , NH 3 -N removal rates are above...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com