Double cross arm suspension guiding mechanism of non-steering wheel

A guide mechanism, double wishbone technology, applied in suspension, elastic suspension, transportation and packaging, etc., can solve problems such as difficulty and time-consuming, and achieve the effect of reducing manufacturing cost, simplifying mechanism design and manufacturing, and reducing types.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

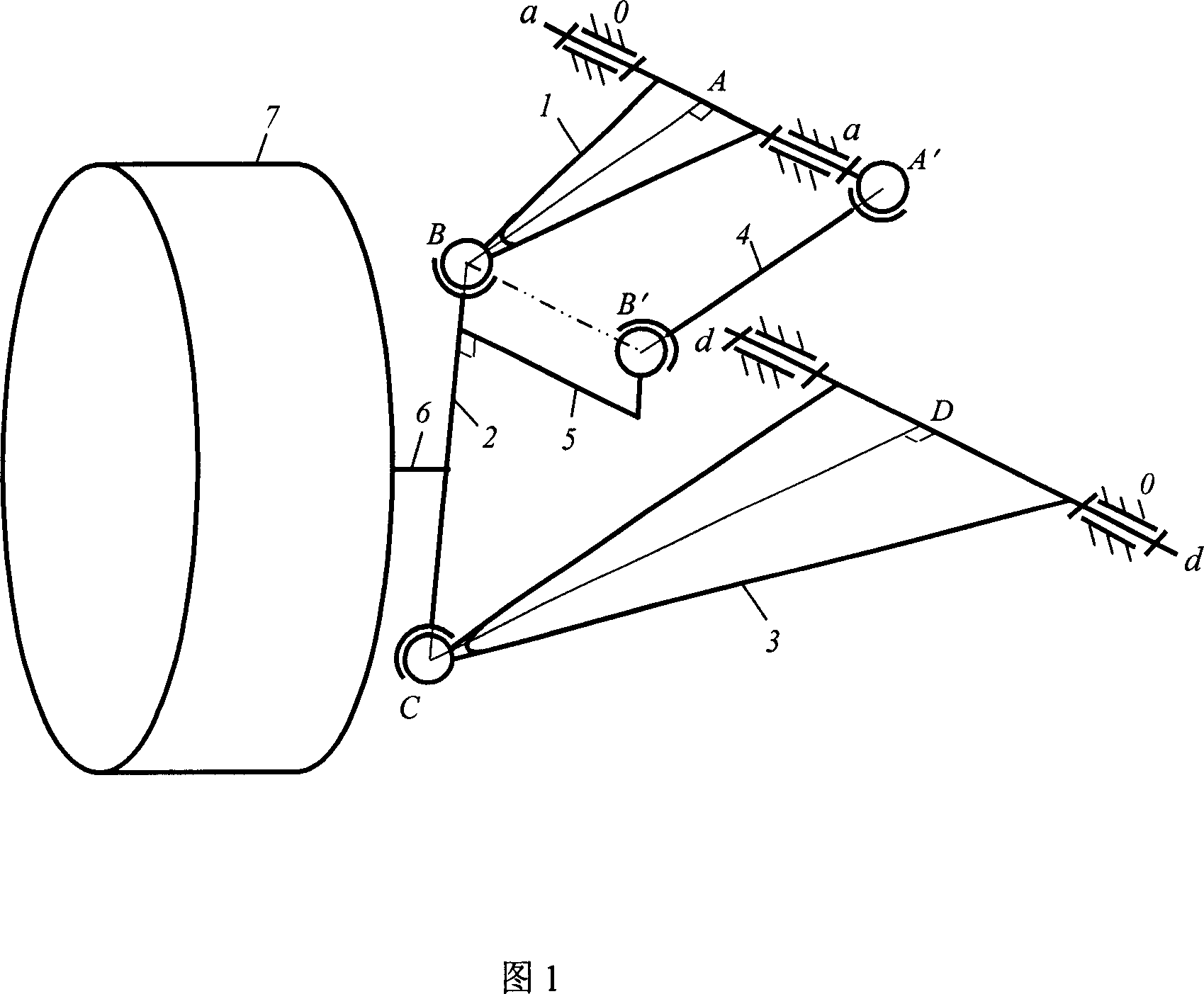

[0007] The present invention will be further described below in conjunction with accompanying drawing 1.

[0008] The present invention comprises vehicle frame 0, upper cross arm 1, steering knuckle 2, lower cross arm 3, double spherical hinge pull rod 4, joint arm 5, axle 6 and wheel 7, wherein one end of upper cross arm 1 is fixed hinge pin shaft aa is hinged with the frame 0, the other end is hinged with a ball joint to the steering knuckle 2 at point B, draw a vertical line from point B to the hinge pin axis aa, intersect the vertical foot at point A, and AB is the length of the upper cross arm 1; The upper end of the steering knuckle 2 and the upper cross arm 1 are hinged at point B with a ball hinge, and the lower end and the lower cross arm 3 are hinged at point C with a ball hinge. BC is the rod length of the steering knuckle 2; one end of the lower cross arm 3 is fixed with a The hinge pin axis d-d is hinged with the frame 0, and the other end is hinged with a ball jo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com