Control system of hydrautic pump

A technology of hydraulic pump and control performance, applied in the field of hydraulic pump, can solve problems such as poor control stability of NFP

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

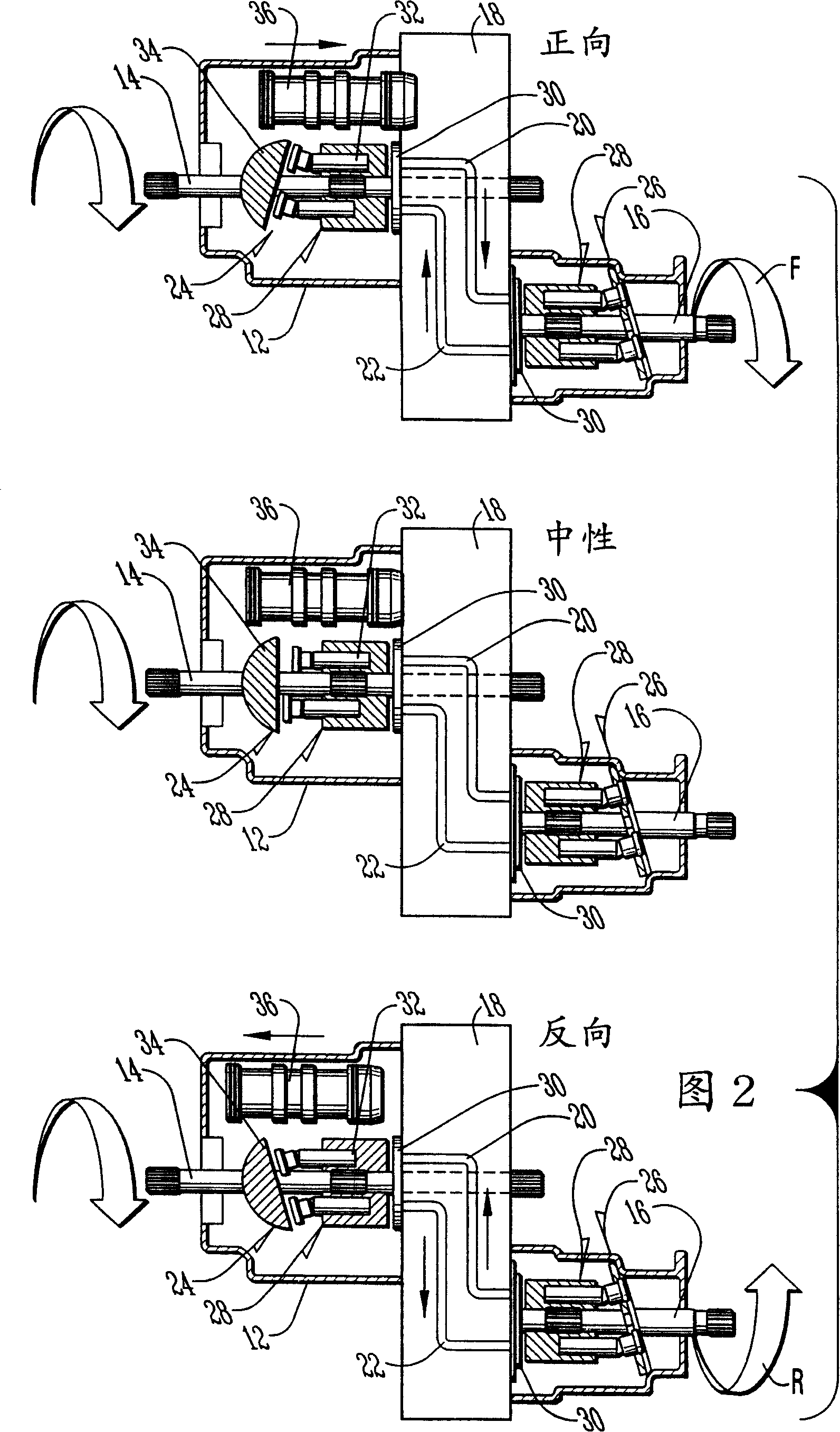

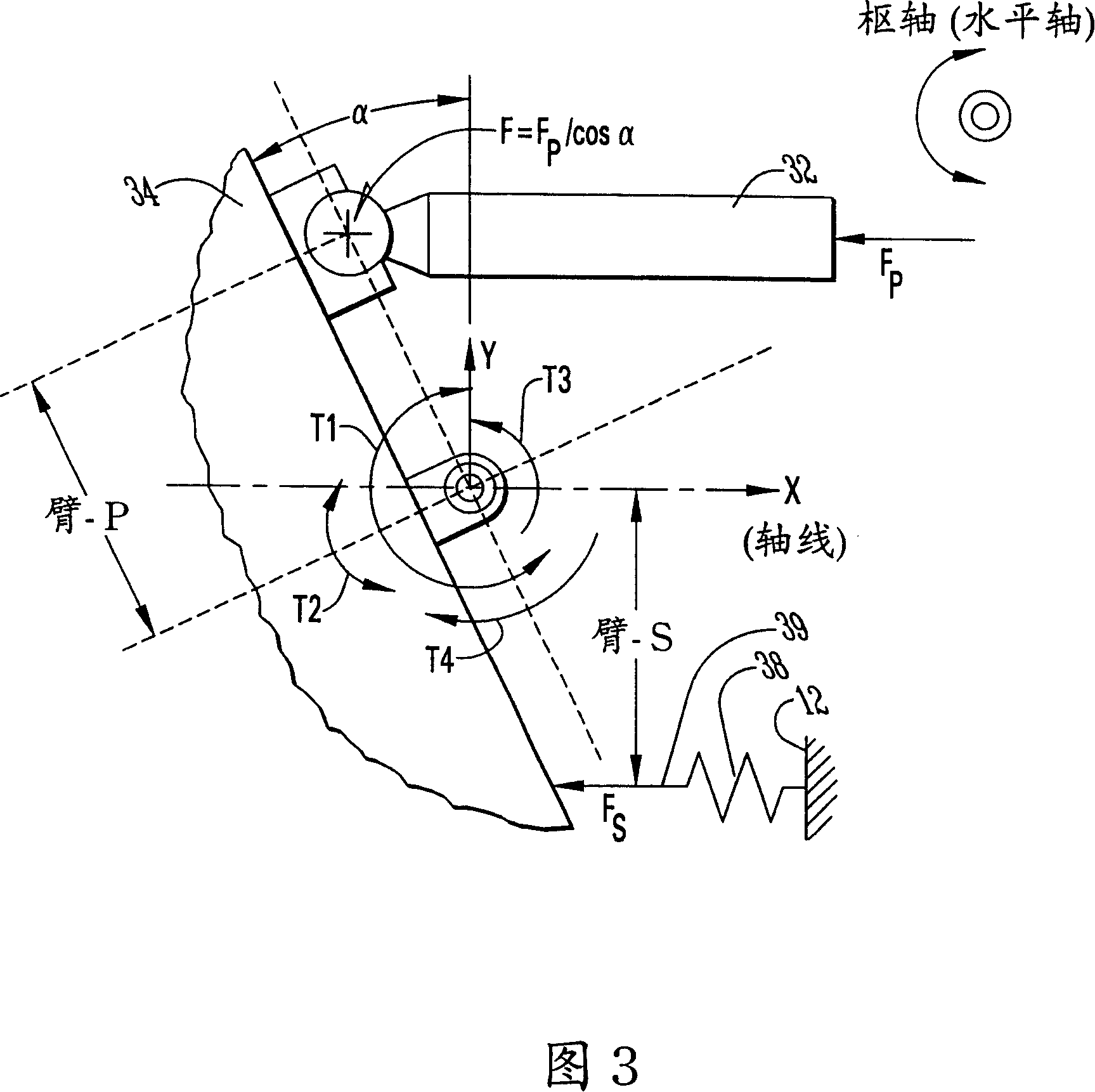

[0026] It is a general object of this invention to control the slope and spacing of the torque curve as a function of speed, system pressure and swash plate angle. This control includes (1) reducing the dependence of the swash plate angle on non-input signal parameters (ie: system pressure and speed); (2) increasing the dependence of the swash plate angle on the input signal; (3) ensuring that the overall operation of the vehicle The stability of speed, pressure and swash plate angle within the range; (4) reduce the vibration and noise of the swash plate in items (1)-(3).

[0027] The above objectives are achieved by combining various known control concepts, fine-tuning some or all of the concepts within certain parameters, which will be described in detail below. Through these concepts a control system is formed which can control the hydraulic transmission to have a control performance similar to that of the DFC system.

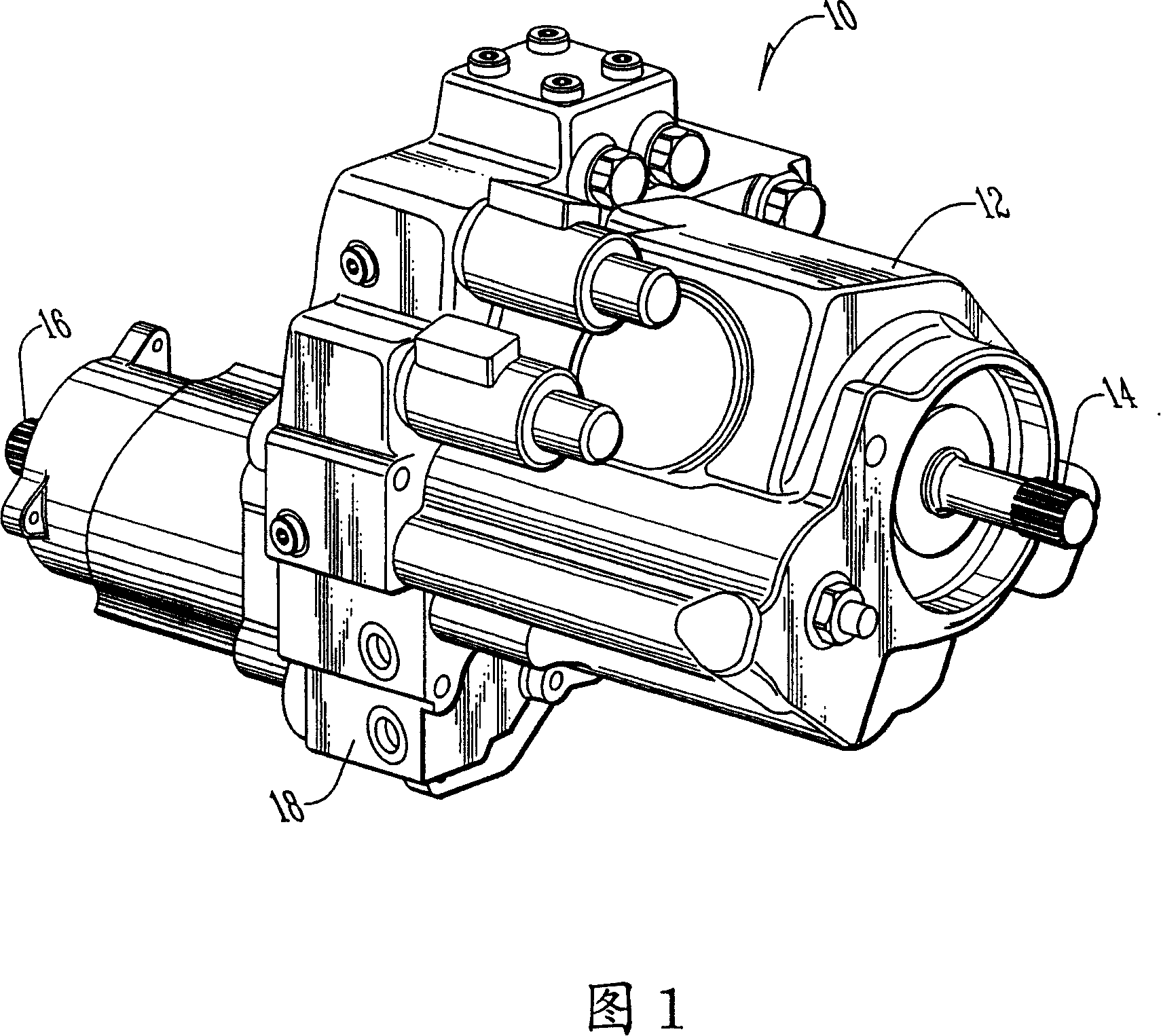

[0028] See Figure 1. A hydraulic transmission 10 for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com