Temperature-pressure sensor

A pressure sensor and temperature sensor technology, applied in thermometers, instruments, scientific instruments, etc., can solve the problems of increasing the number of openings, unfavorable data fusion and data compensation, and difficulty in ensuring the identity of the measured points, etc., to achieve simplified structure and process , to ensure the effect of identity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

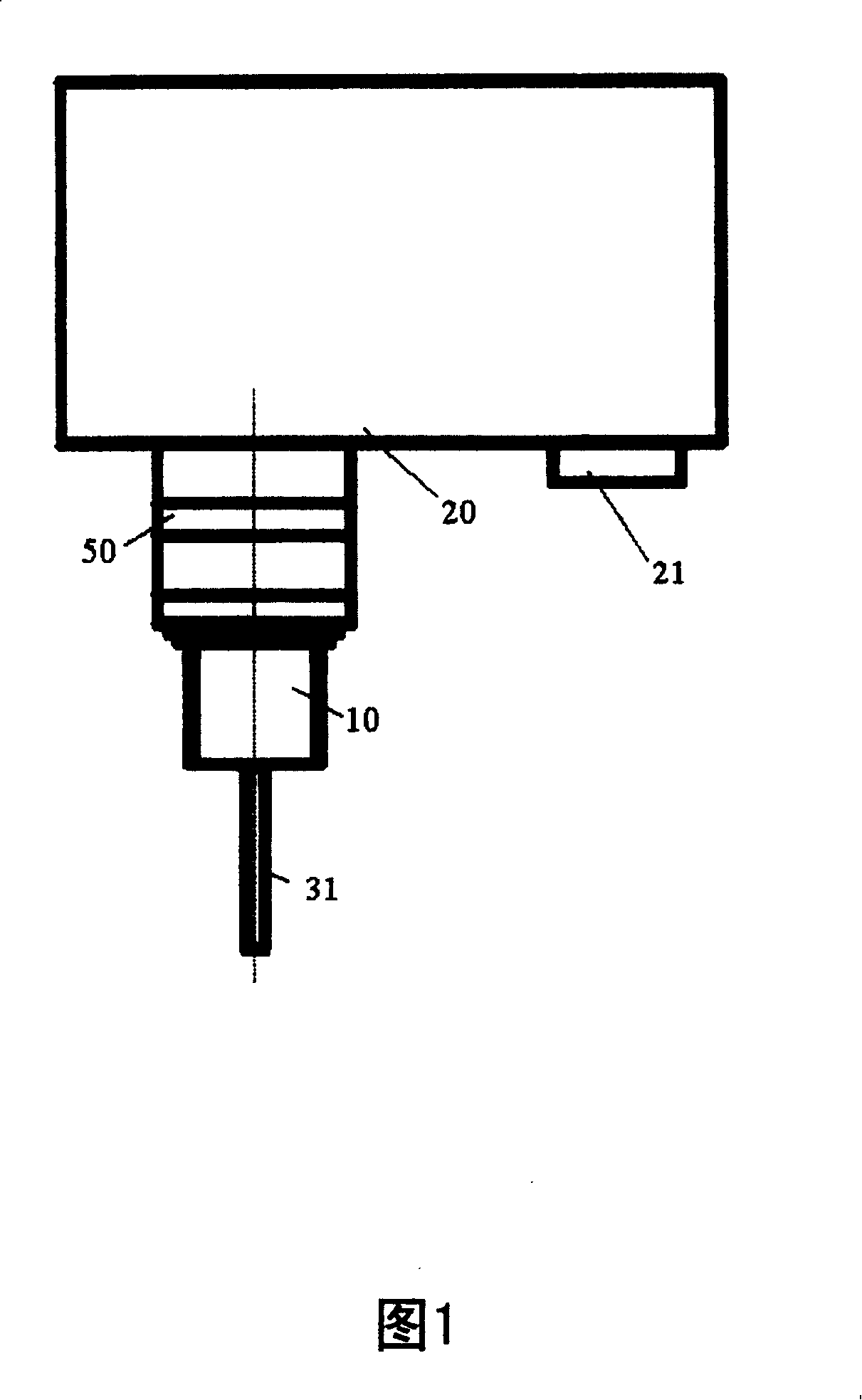

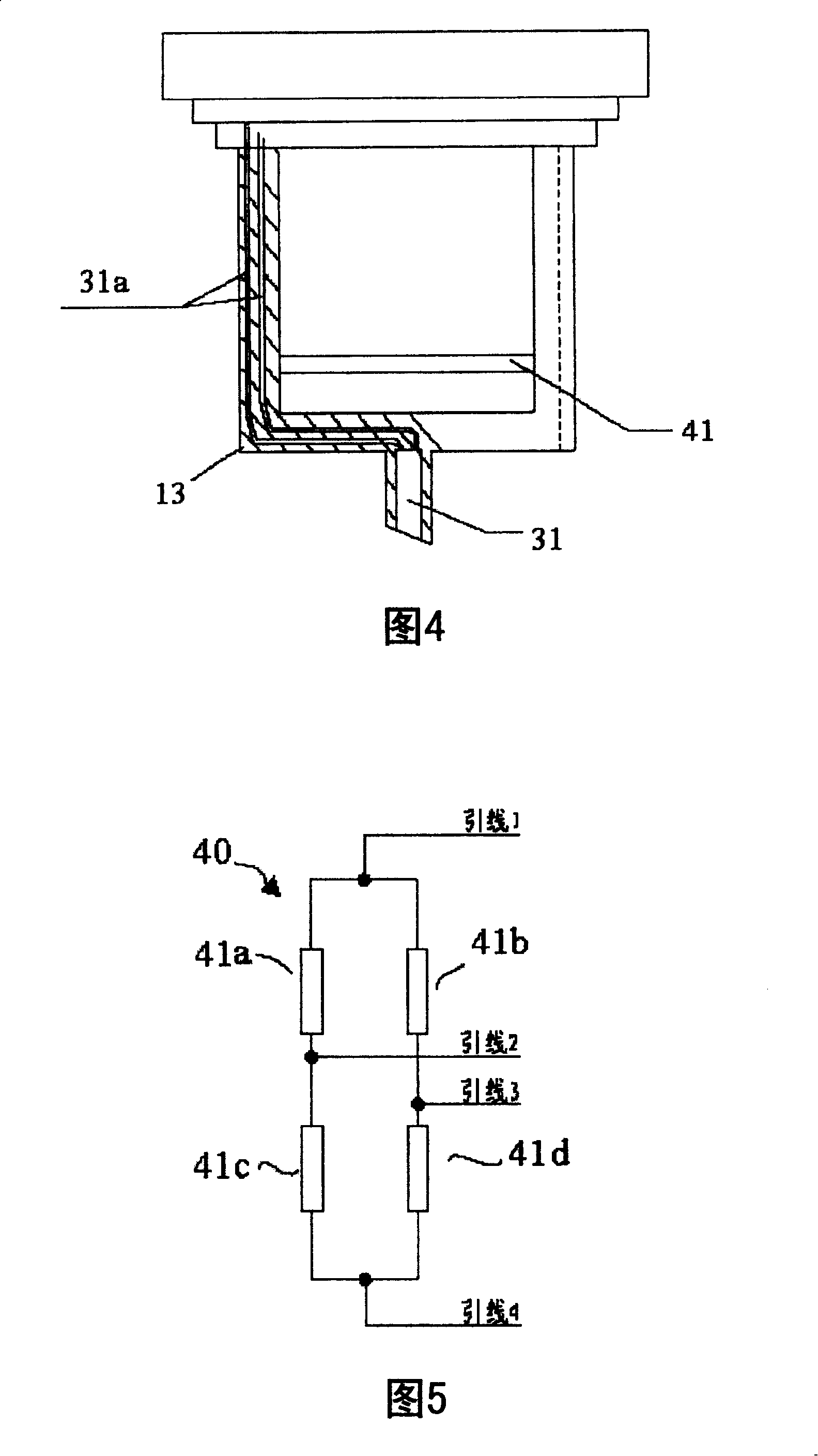

[0015] Referring to Fig. 1, the temperature and pressure sensor of the present invention includes a housing 100, which is composed of a probe body 10 and a cavity 20 connected to the probe body 10, and the housing 100 also includes a temperature sensing element 31, four pressure sensing elements 41, A temperature sensor circuit 30 and a pressure sensor circuit 40 . The temperature sensor circuit 30 and the pressure sensor circuit 40 are disposed in the cavity 20, and they are disposed on a circuit board (not shown). The cavity 20 can be made of aluminum alloy, which has high strength and light weight. The lower end of the cavity 20 is provided with a line inlet 21 for circuit board power lines and signal lines. The line entrance 21 adopts a stuffing box and has a waterproof function.

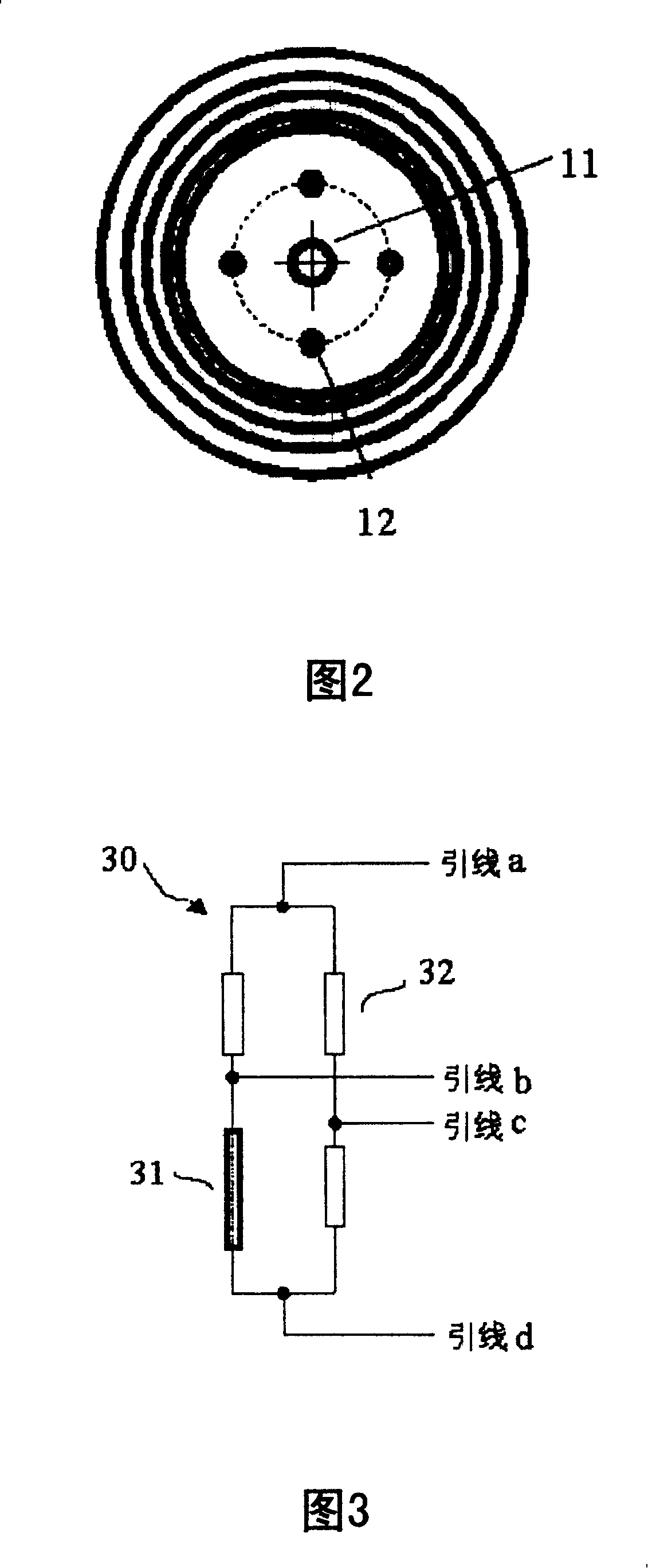

[0016] The probe body 10 is used to detect temperature and pressure parameters. Its structure is shown in FIG. On a circle with the center of the following end face as the center and any radiu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com