Elastic insulation component for wedging up winding of electric machine, especially stator winding

A technology for stator windings and components, which is applied to electrical components, electric components, windings, etc., and can solve problems such as loose windings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

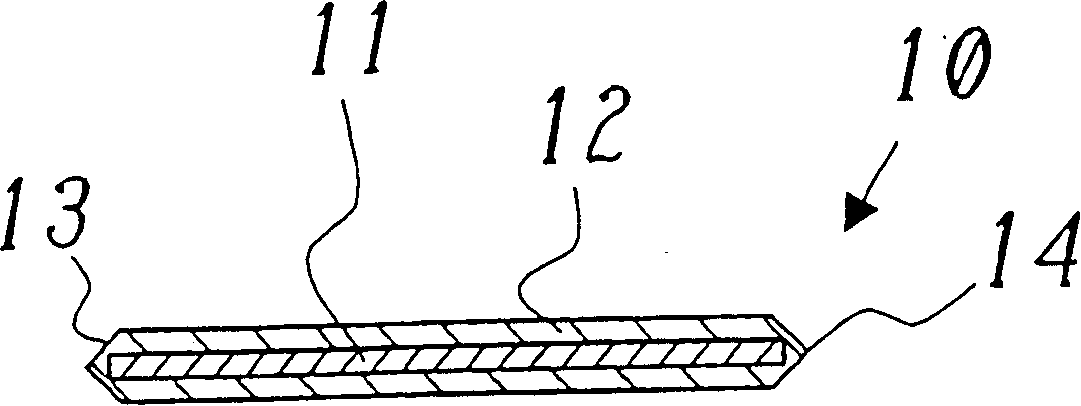

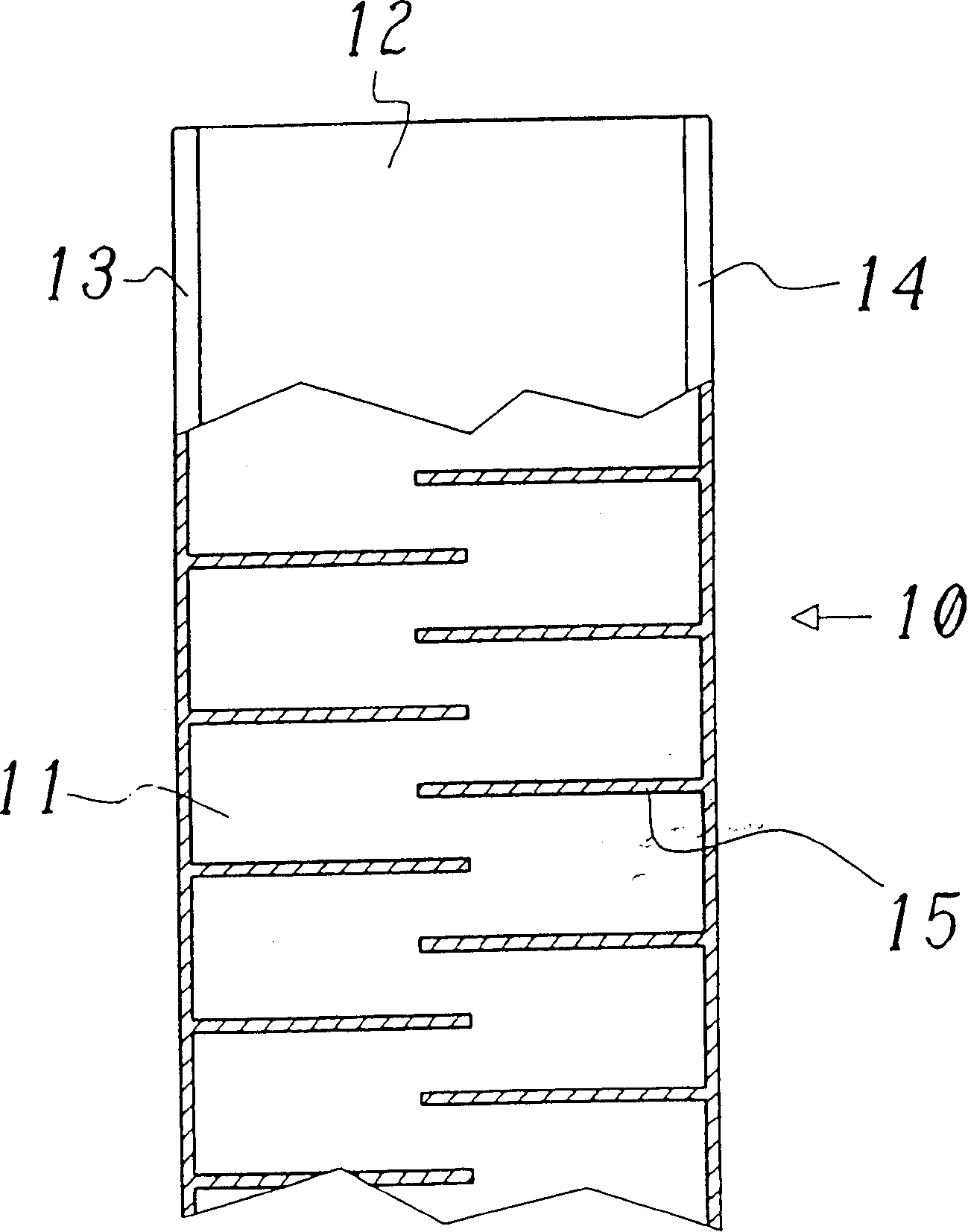

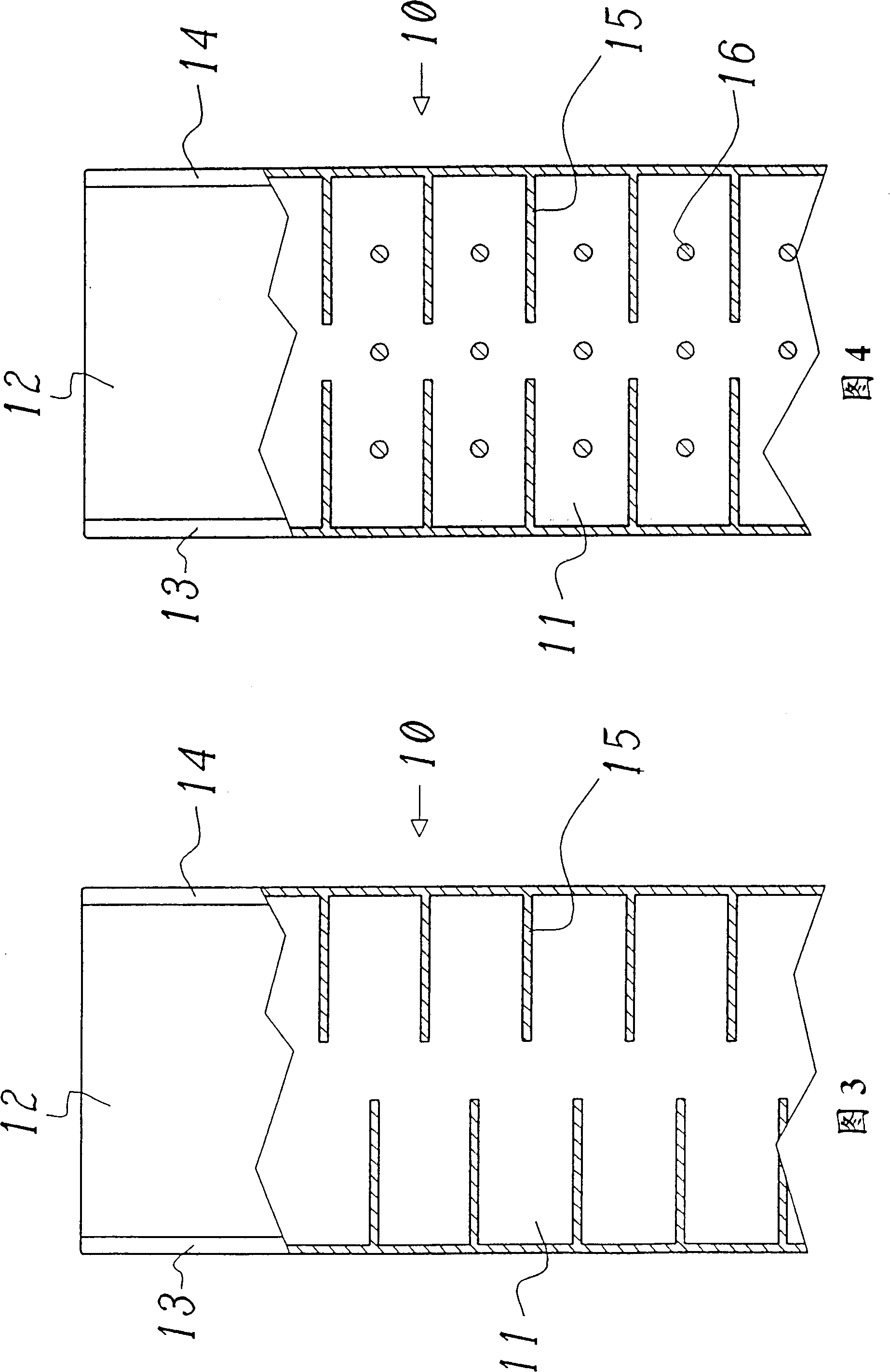

[0030] figure 1 and figure 2 A first preferred embodiment of the insulating material element according to the invention in the construction of the slot connection wedge 10 is shown in cross-section and in a partially sectioned top view. The groove connecting wedge 10 is formed as a flat elongated strip and is limited laterally by two V-shaped longitudinal sides 13, 14, so that a prismatic cross-section ( figure 1 ), which is generally and characteristically used for slot joint wedges. The slot wedge 10 contains a flat strip-shaped metal spring core 11 which is surrounded on all sides by a sheath 12 of insulating material which brings the core into direct contact with the stacked plates of the stator and thereby prevents Hazard of stray currents with hot spots and a large number of panel connections. The metal spring core 11 preferably has a simple rectangular cross-section and has a thickness of a few millimeters, in particular in the range of 2 to 3 mm. It preferably con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com