Thermosetting formaldehyde-free fluorescent pigment powder and preparation method thereof

A fluorescent pigment and thermosetting technology, used in the fields of plastic and textile printing pastes and organic pigments, can solve the problems of irregular product particles, poor temperature resistance, large dust, etc., achieve uniform powder particle size distribution, improve thermal performance, The effect of shape rules

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following examples are further illustrations of the present invention, but the present invention is not limited thereto.

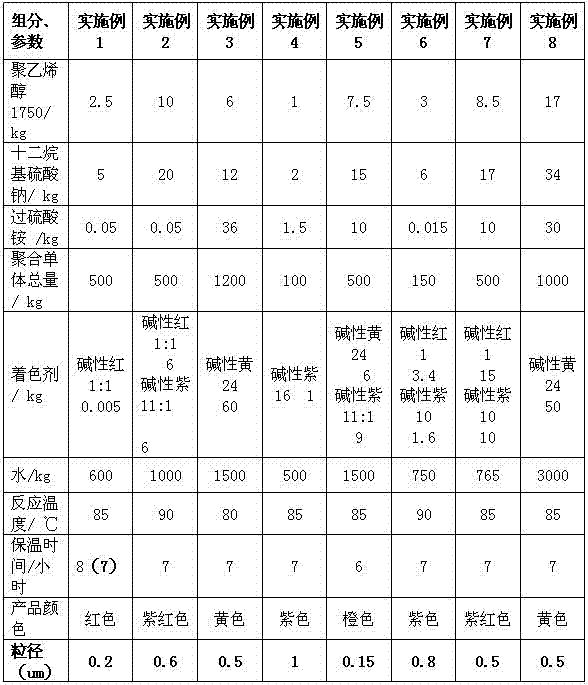

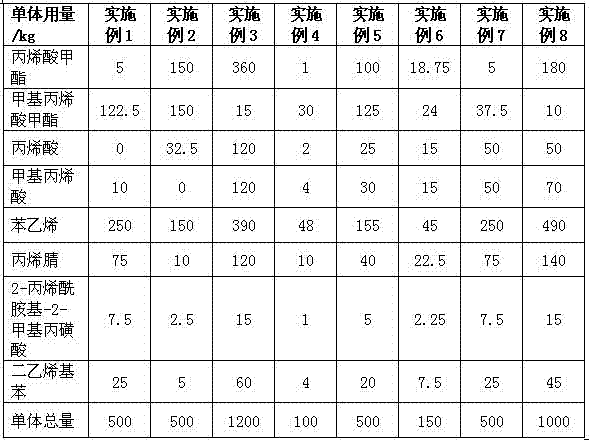

[0025] Embodiment 1-8 prepares the raw material of thermosetting formaldehyde-free fluorescent pigment powder as shown in table 1, and monomer component is shown in table 2:

[0026] Table 1 The original components and synthesis process parameters of thermosetting formaldehyde-free fluorescent pigment powder

[0027]

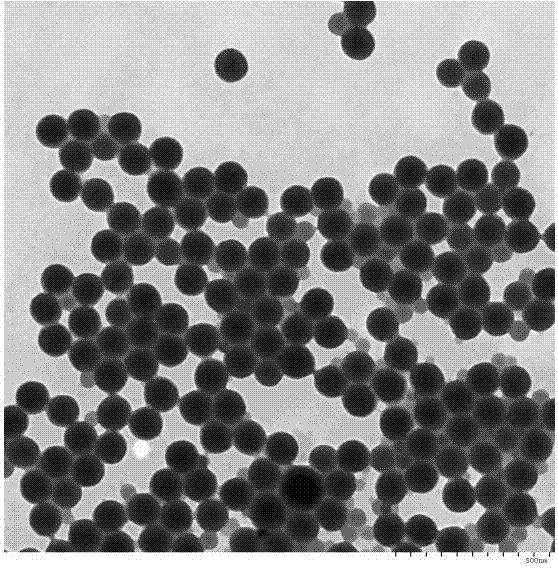

[0028] The particles obtained in Examples 1-8 are in the form of microspheres, the particle size distribution is uniform and regular, and the heat resistance is good.

[0029] It can withstand the injection molding process at 300°C for five minutes, and the pigment does not change color, fade or migrate.

[0030] Table 2 Polymerized monomer ratio of thermosetting formaldehyde-free fluorescent pigment powder (unit: Kg)

[0031]

[0032] The preparation process of embodiment 1-8 is as follows:

[0033]Add water, polyvinyl a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com