Aqueous nano metal color paste

A nano-metal and nano-metal particle technology, applied in the direction of pigment paste, etc., can solve the problems of narrow application field, color paste stability, poor dispersion, no metallic luster, etc., achieve good gloss, easy storage and transportation, The effect of preventing subsidence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

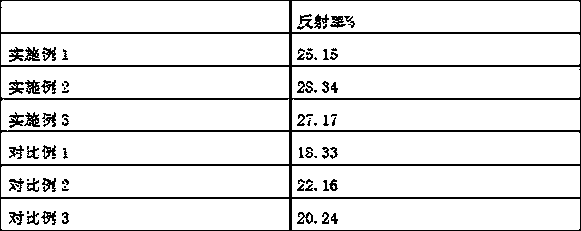

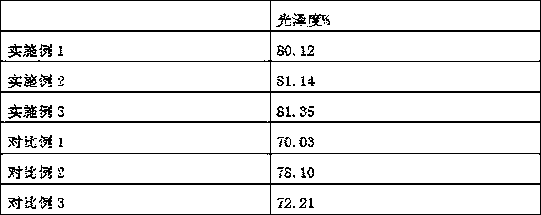

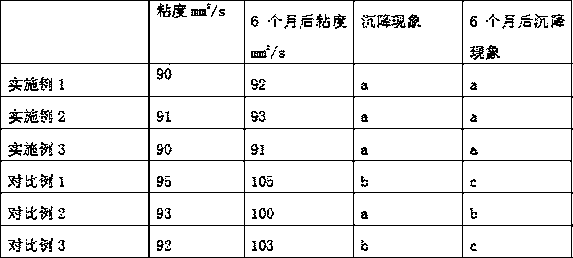

Examples

Embodiment 1

[0019] A water-based nano metal color paste is made of the following components in parts by weight: modified nano metal particles 25, toner 6, nano inorganic filler 5, wetting agent 3, dispersant 6, deionized water 60.

[0020] Further, the preparation method of the modified nano-metal particles is as follows: in a high-vacuum reaction chamber, the metal is heated and sublimated to form a metal gas, and then the metal gas rises to gather on the low-temperature resin film and condenses into nano-sized ultrafine particles, which will contain The resin film of ultrafine particles is dissolved in an organic solvent, and then subjected to suction filtration to collect ultrafine particles. The ultrafine particles are collected by a high-current pulsed ion beam pair composed of an ion beam with an ion energy of 246keV, a beam current density of 160A / cm², and a pulse width of 60ns. Ultrafine particles are subjected to surface irradiation treatment, and then the irradiated ultrafine par...

Embodiment 2

[0031] A water-based nano metal color paste is made of the following components in parts by weight: modified nano metal particles 30, toner 8, nano inorganic filler 10, wetting agent 5, dispersant 8, deionized water 80.

[0032] Further, the preparation method of the modified nano-metal particles is as follows: in a high-vacuum reaction chamber, the metal is heated and sublimated to form a metal gas, and then the metal gas rises to gather on the low-temperature resin film and condenses into nano-sized ultrafine particles, which will contain The resin film of ultrafine particles is dissolved in an organic solvent, and then subjected to suction filtration to collect ultrafine particles. The ultrafine particles are collected by a high-current pulsed ion beam pair composed of an ion beam with an ion energy of 246keV, a beam current density of 160A / cm², and a pulse width of 60ns. Ultrafine particles are subjected to surface irradiation treatment, and then the irradiated ultrafine pa...

Embodiment 3

[0043] A water-based nano metal color paste is made of the following components in parts by weight: modified nano metal particles 28, toner 7, nano inorganic filler 8, wetting agent 4, dispersant 7, and deionized water 70.

[0044]Further, the preparation method of the modified nano-metal particles is as follows: in a high-vacuum reaction chamber, the metal is heated and sublimated to form a metal gas, and then the metal gas rises to gather on the low-temperature resin film and condenses into nano-sized ultrafine particles, which will contain The resin film of ultrafine particles is dissolved in an organic solvent, and then subjected to suction filtration to collect ultrafine particles. The ultrafine particles are collected by a high-current pulsed ion beam pair composed of an ion beam with an ion energy of 246keV, a beam current density of 160A / cm², and a pulse width of 60ns. Ultrafine particles are subjected to surface irradiation treatment, and then the irradiated ultrafine ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com