Flexible powder band for automatic overlay welding

An automatic surfacing and powder technology, applied in the direction of welding medium, welding equipment, welding equipment, etc., can solve the problems of inability to surfacing, inability to solidify, powder leakage, etc., to achieve uniform weight of powder belt laying, accurate composition of surfacing layer The effect of accurate surfacing composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

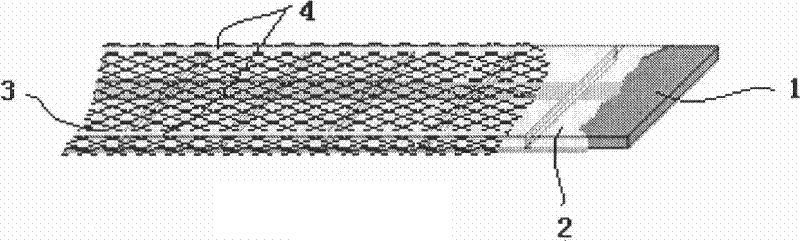

Image

Examples

Embodiment Construction

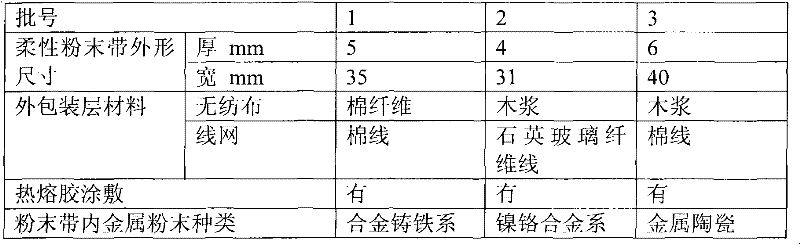

[0021] According to the technical scheme of the present invention, three batches of flexible powder belts have been prepared.

[0022] Examples Table 1 shows the types of the outer packaging material non-woven fabric and wire mesh material of the flexible powder belt. The overall dimensions of the flexible powder belt and the types of metal powder in the powder bag are also listed in Table 1. Adhesives and hot-melt adhesive films used are conventional commercially available adhesives and hot-melt adhesives.

[0023] Using the flexible powder belt of Embodiment 1 of the present invention, the wear-resistant layer is surfacing on the metal surface of the low carbon steel. Results: The surfacing process is stable, the hardness of the surfacing layer measured after surfacing is HRC 62-65, and the surface of the surfacing layer is well formed.

[0024] Table 1 The three-layer composition of the outer packaging material of the flexible powder tape of the embodiment, the type of me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com