Water channel pre-filling method used during lost foam casting of engine cylinder body

A technology of engine cylinder block and lost foam casting, which is applied in the direction of casting molding equipment, molds, mold components, etc. It can solve the problems of channel blockage flow, high labor intensity of workers, and low efficiency, so as to meet the pressure resistance and reduce pressure. The effect of small cleaning workload and reduced labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

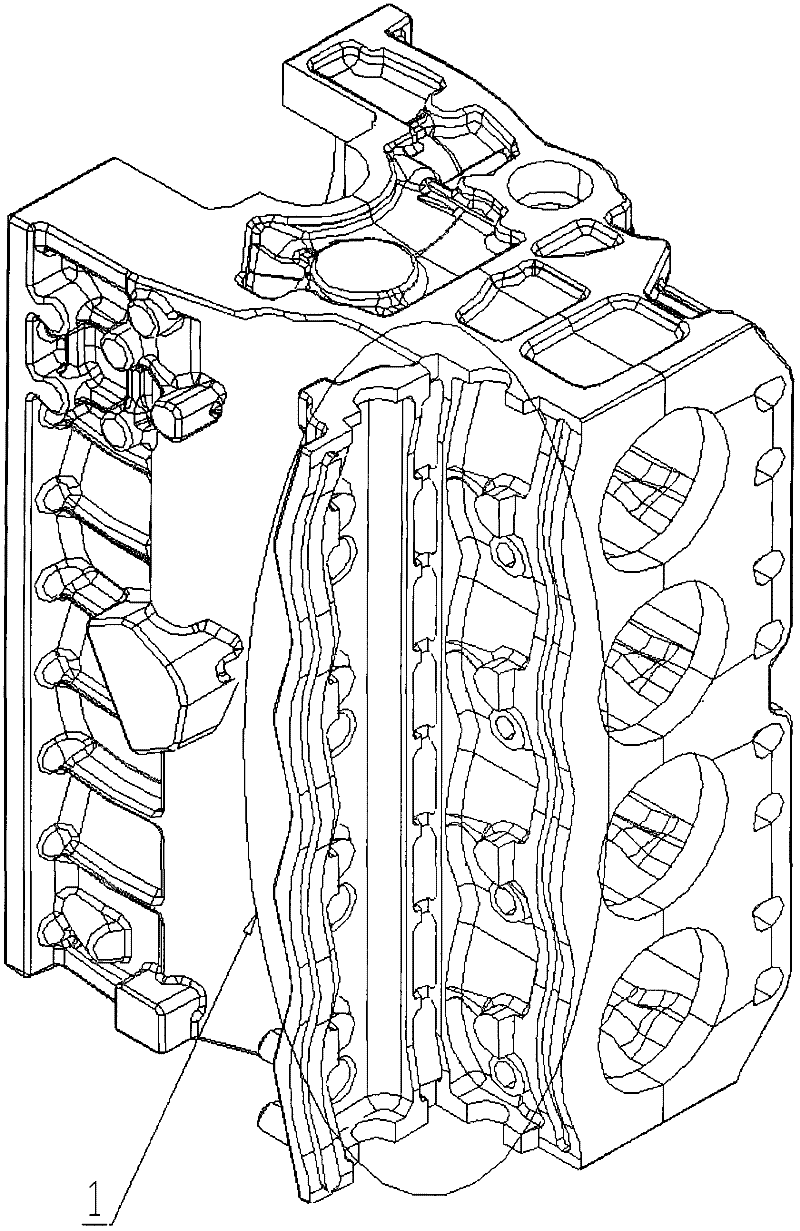

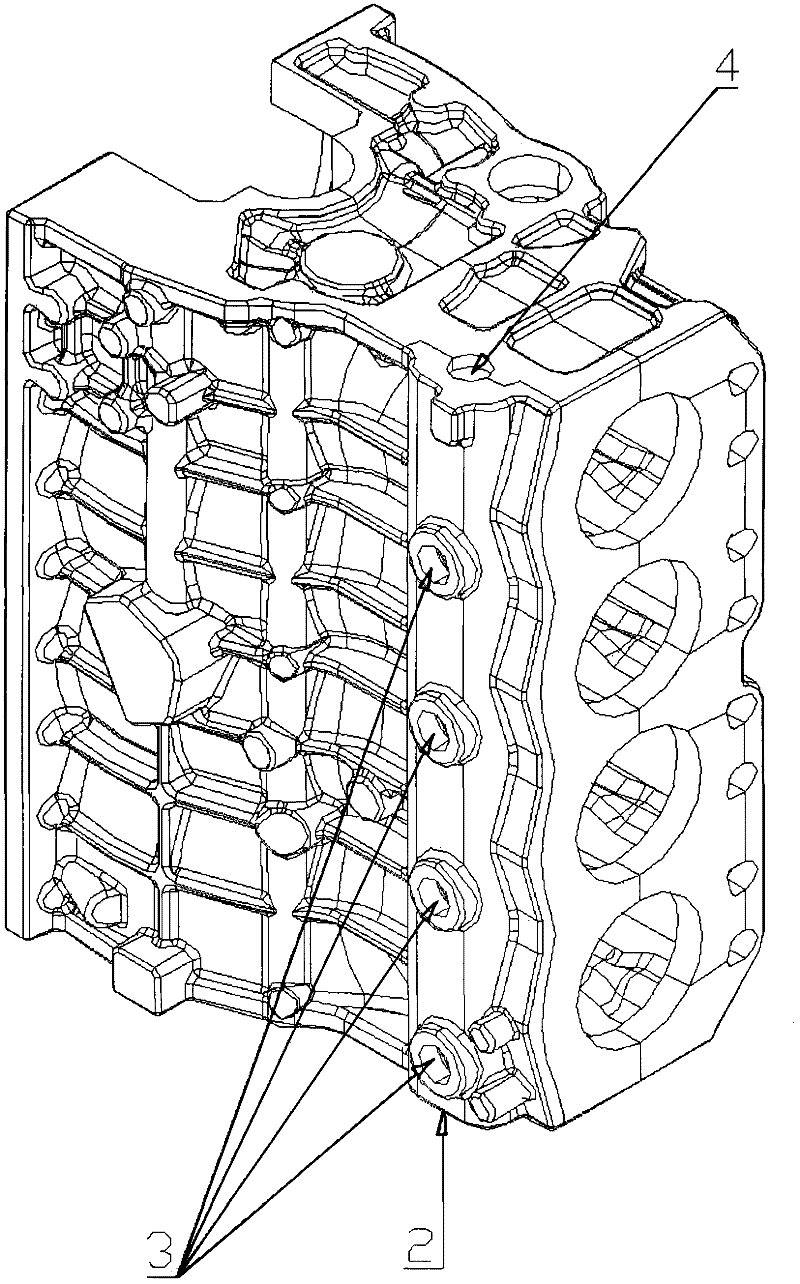

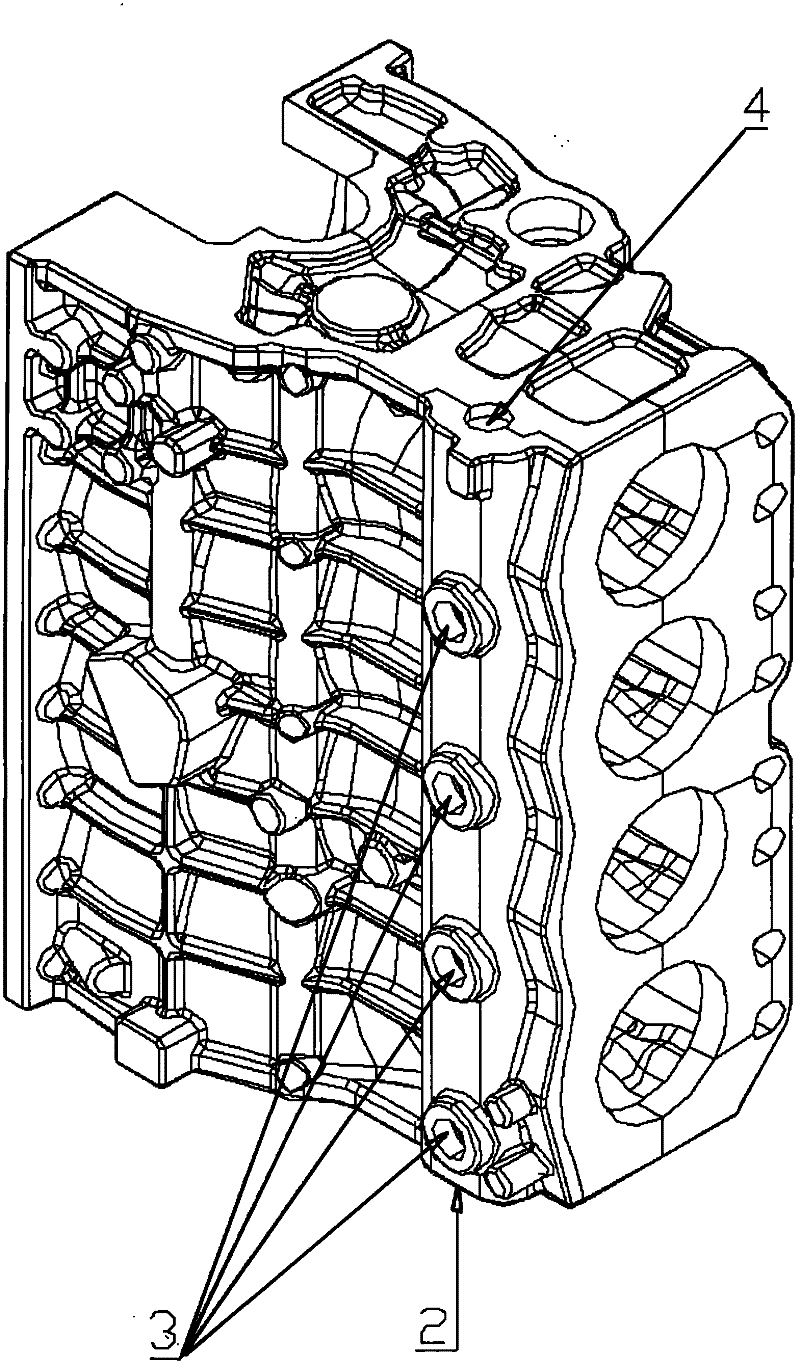

[0023] An existing engine block is cast by the lost foam method, and the lost foam model is ready, and now the water channel is pre-filled. figure 1 shown) on the workbench, and then figure 2 As shown, the lower sealing port 2 of the waterway hole is blocked with glass sand, the side hole 3 of the waterway 1 is sealed with glass cloth and hot melt adhesive, and only one port 4 is left as a sand filling port. ② Put the model in the three-dimensional vibrating sand box, and the lower plugging port 2 of the plugging end is down, so that the direction of the channel hole is consistent with the sand feeding direction, that is, the hole between the lower plugging port 2 and the port 4 is parallel to the sand feeding direction. ③Inject a specified amount of dry sand into the waterway 1 at a constant speed through the port 4 of the waterway 1, and after shaking to the specified compactness, then block the port 4 with water glass sand, so that the waterway becomes a closed state. ④ A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com