Method for recognizing work in die bonder and die bonder

A technology of attachment device and identification method, which is applied in the direction of electrical components, electric solid devices, semiconductor devices, etc., can solve the problems of high price, long time, and high price of chip attachment devices, and achieve the elimination of useless bonding time, increase productivity, and reduce costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

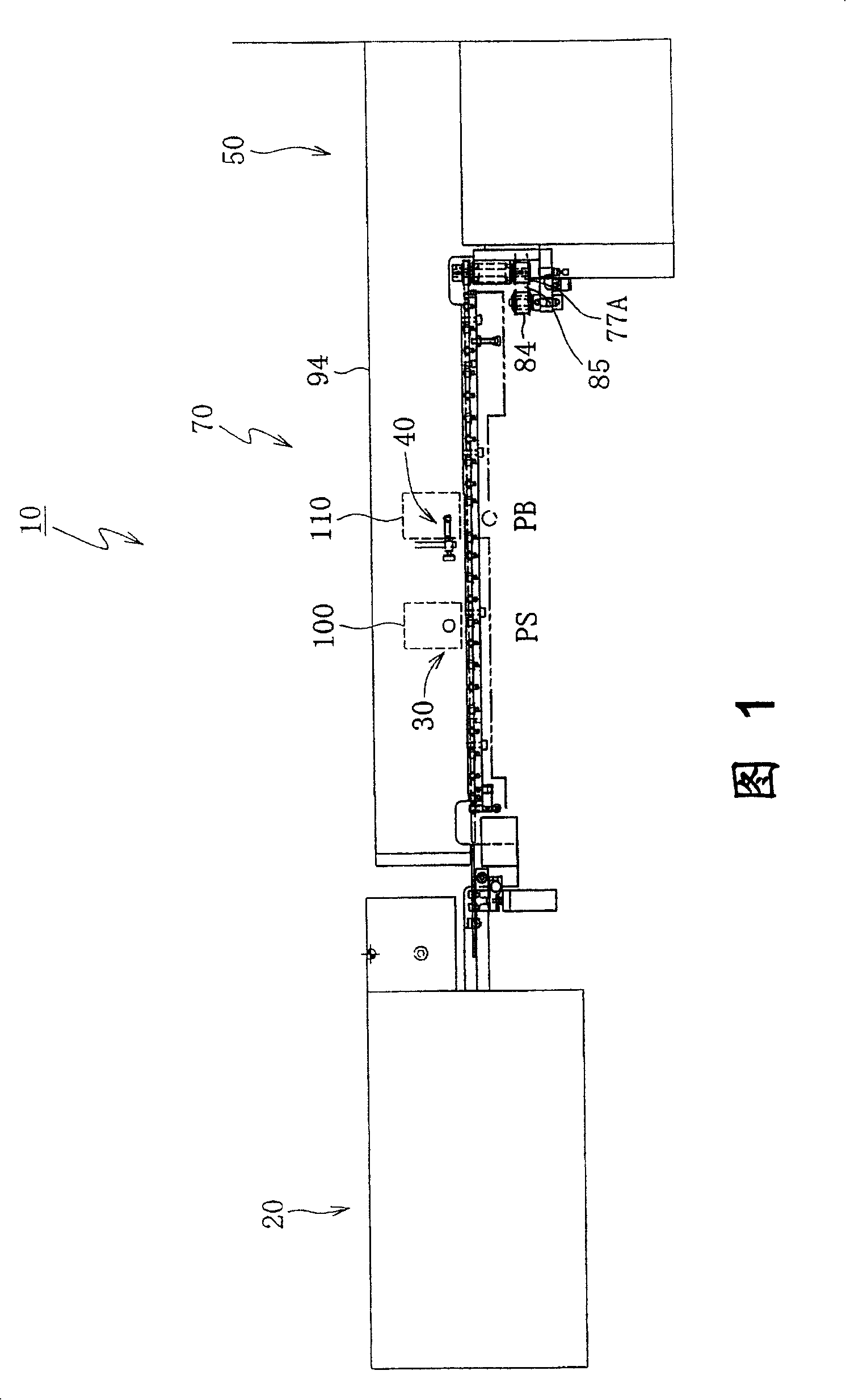

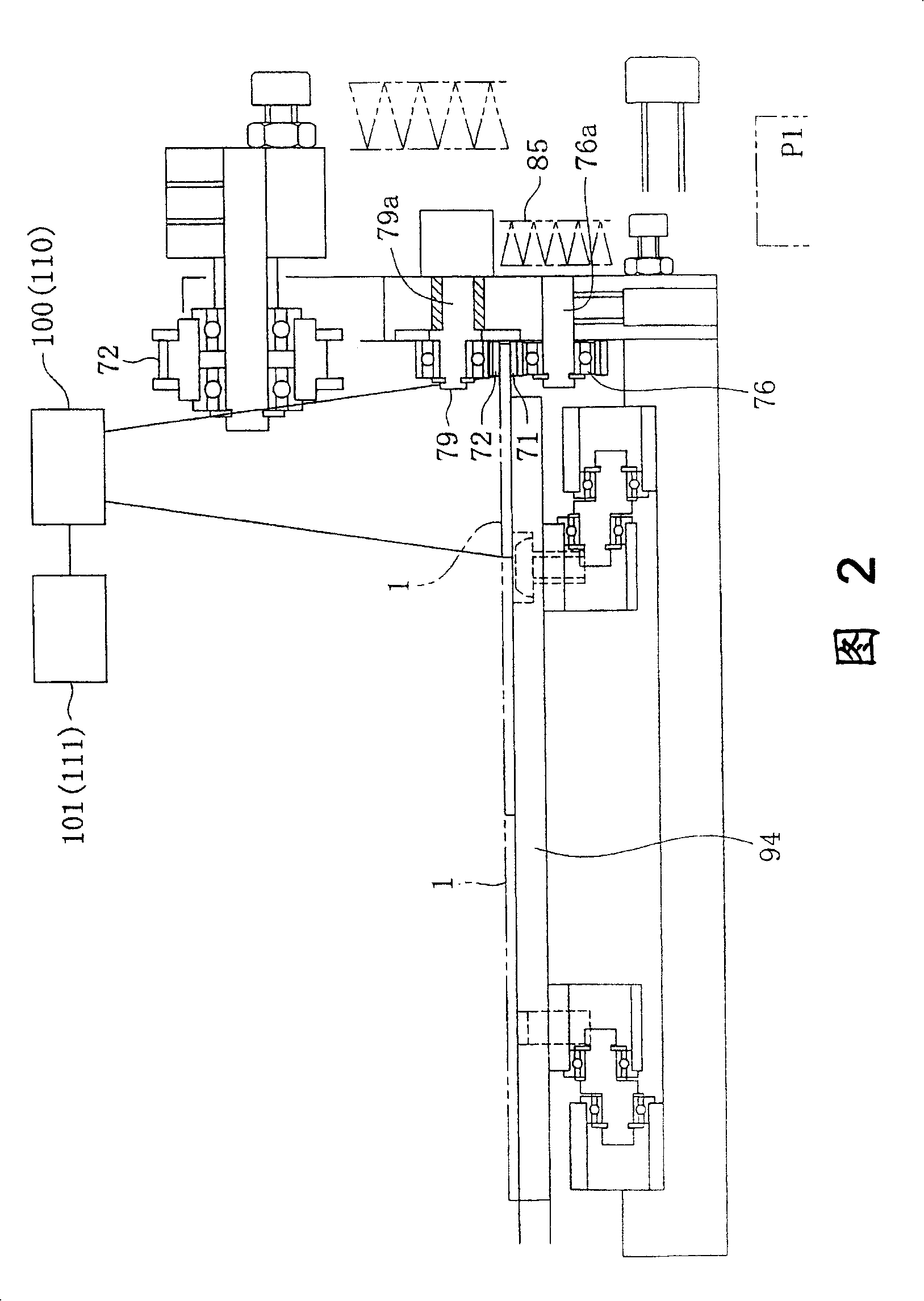

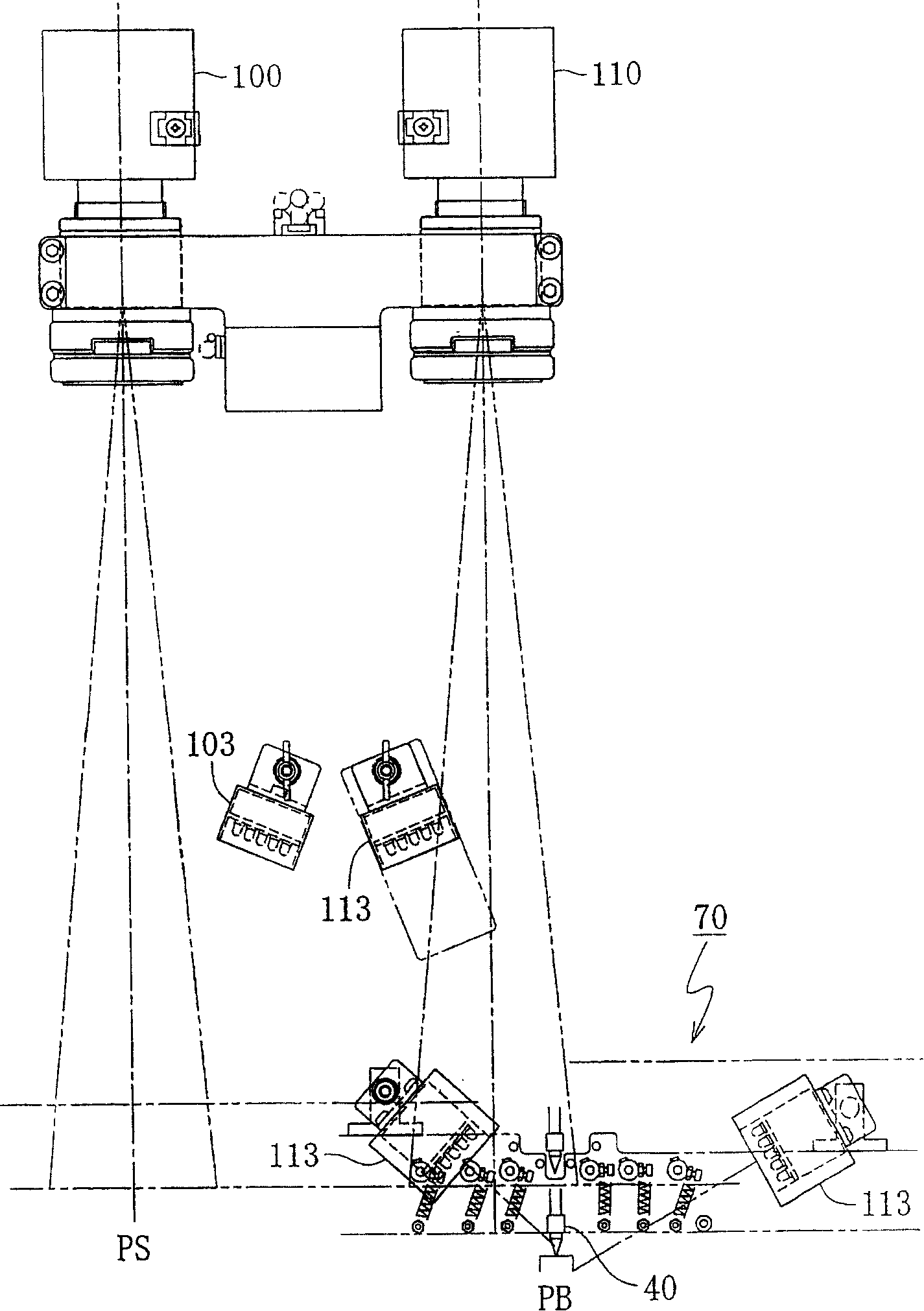

[0113] Next, an embodiment of a die attach apparatus employing the workpiece recognition method of the present invention will be described with reference to the drawings.

[0114] The chip attaching device 10 is shown in Fig. 1- image 3 As shown, it includes: a loader 20 for supplying a substrate 1 having a plurality of bonding regions such as a lead frame and a printed circuit board as an example of a workpiece, a transport device 70 for transporting the substrate 1 , and a transport device 70 in the transport device 70. The bonding material coating position PB on the front side of the halfway portion of the substrate 1 applies the bonding material to the bonding material coating device 30 on the substrate 1, and the bonding material coating position PB on the front side of the midway portion of the transport device 70 applies the bonding material to the substrate 1. Bonding head 40 (bonding head) for bonding semiconductor chip (chip) (die) on substrate 1 of bonding material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com