Method for purifying mouse herve growth factor for scale-production

A technology of nerve growth factor and purification method, which is applied in the field of preparation of mouse nerve growth factor, can solve the problems of affecting production efficiency, increasing protein pollution, long production cycle, etc., and achieves the goal of improving production efficiency, fast flow rate and high load Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0023] A method for purifying mouse nerve growth factor suitable for large-scale production, the specific operation method is as follows:

[0024] 1. Submandibular Gland Treatment

[0025] Take out the frozen submandibular gland of male mice, after thawing, add 5 times pre-cooled high-pressure sterilized water, and put it into a homogenizer for homogenization. After homogenization, the homogenate was allowed to stand at 4°C for 30 minutes, centrifuged at 12,000 rpm for 30 minutes, and the supernatant was collected. The supernatant was ultrafiltered to pH 6.8 with a hollow fiber column with a molecular weight cut-off of 10K, and placed in a 20 mmol / L PB solution.

[0026] 2. Sepharose XL (SP XL) (Sepharose SP XL column) chromatography

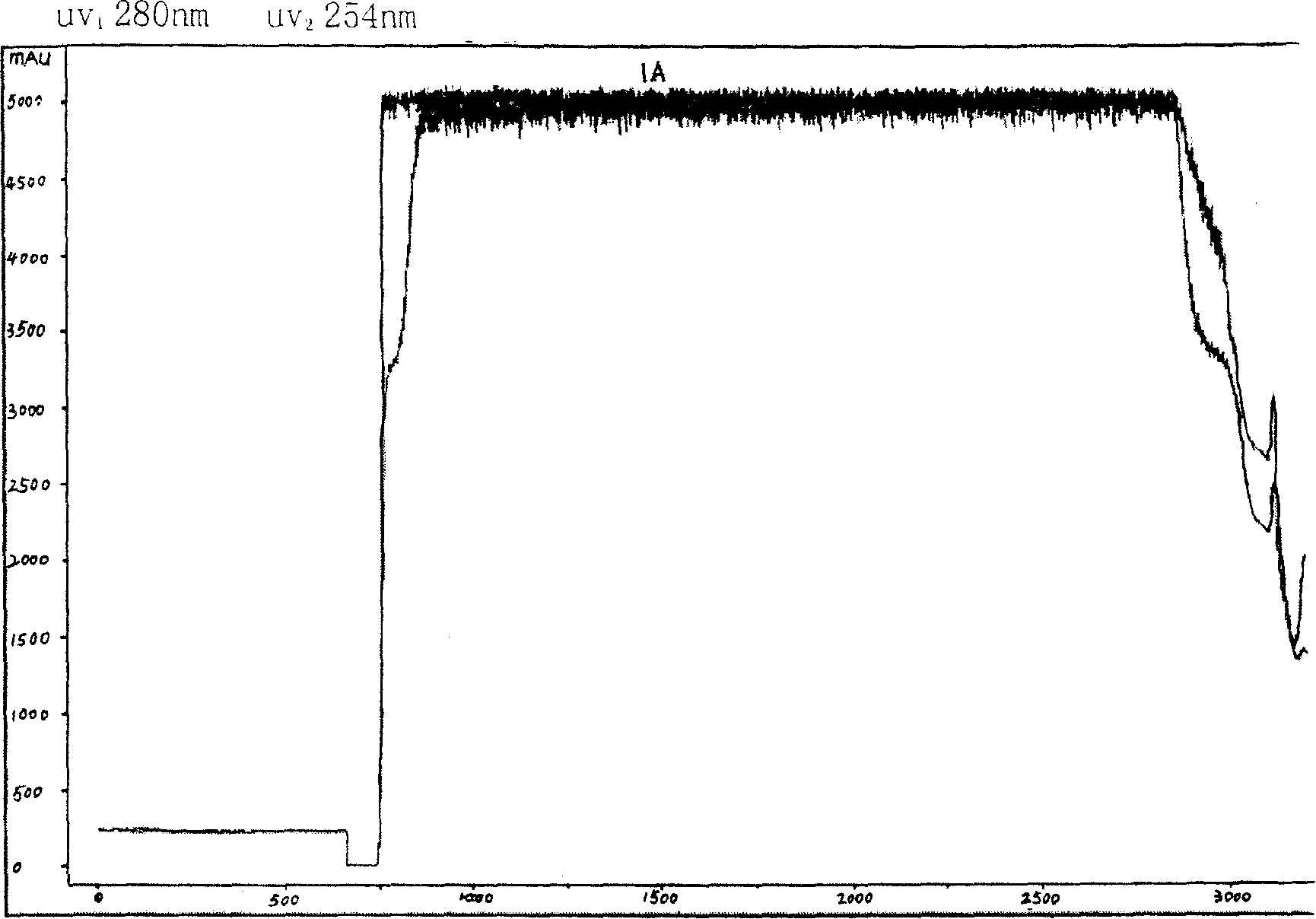

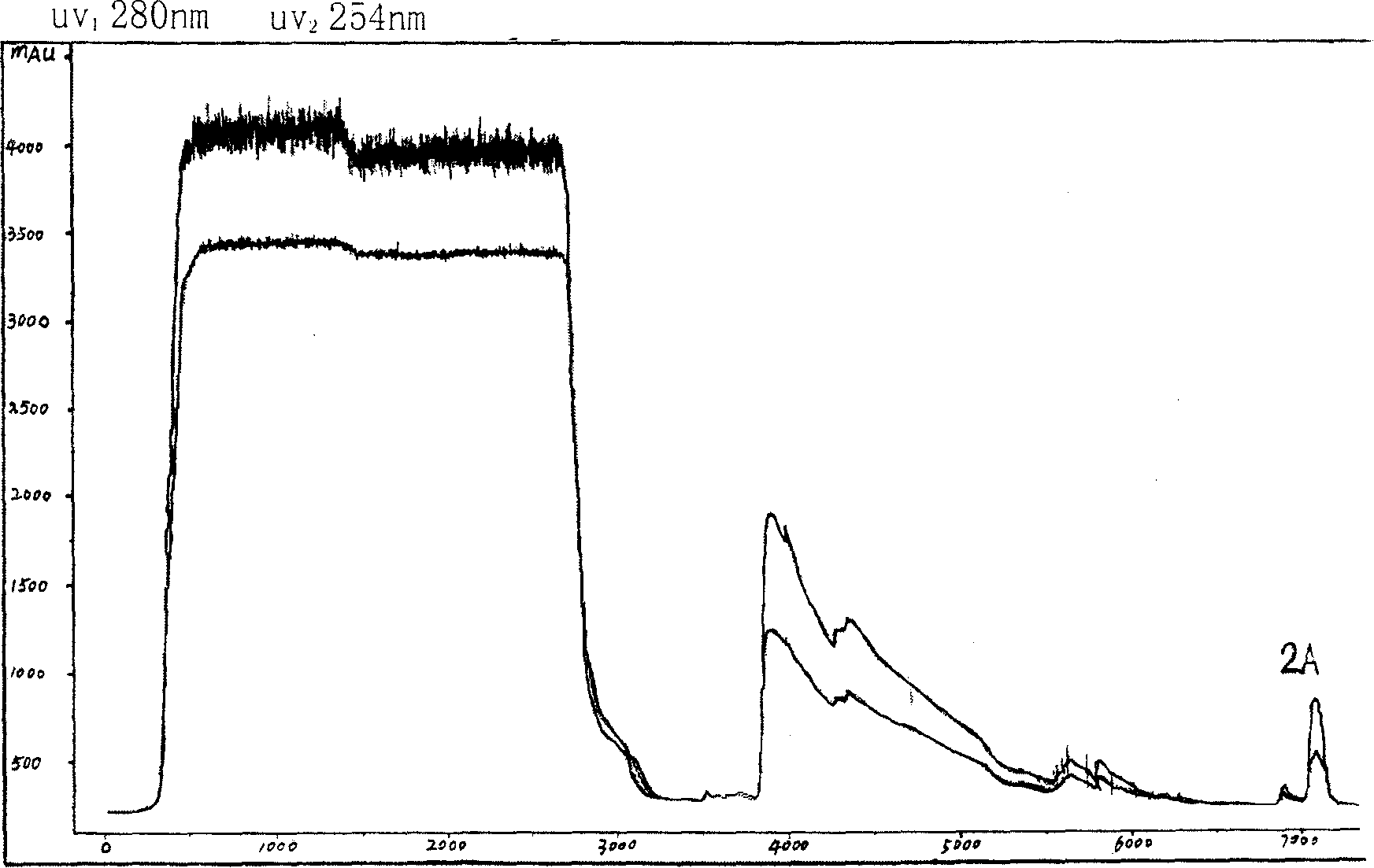

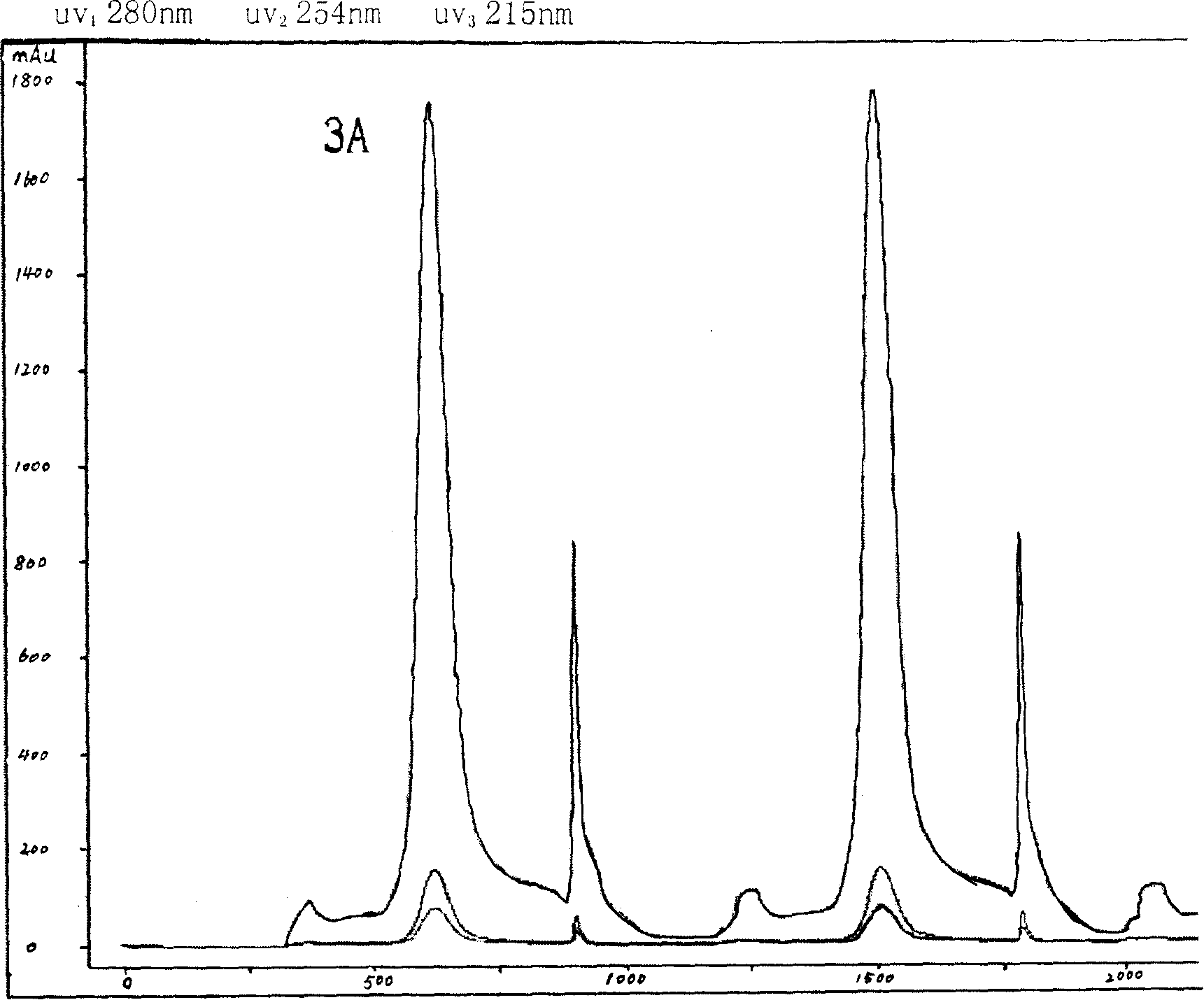

[0027] The ultrafiltered supernatant was loaded onto a Sepharose XL cation-exchange column (XK 26 / 50, Amersham Biosciences) at pH 6.8, 20mmol / L PB solution equilibrated, flow rate 10ml / min, and the flow-through was collected. See figure 1 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com