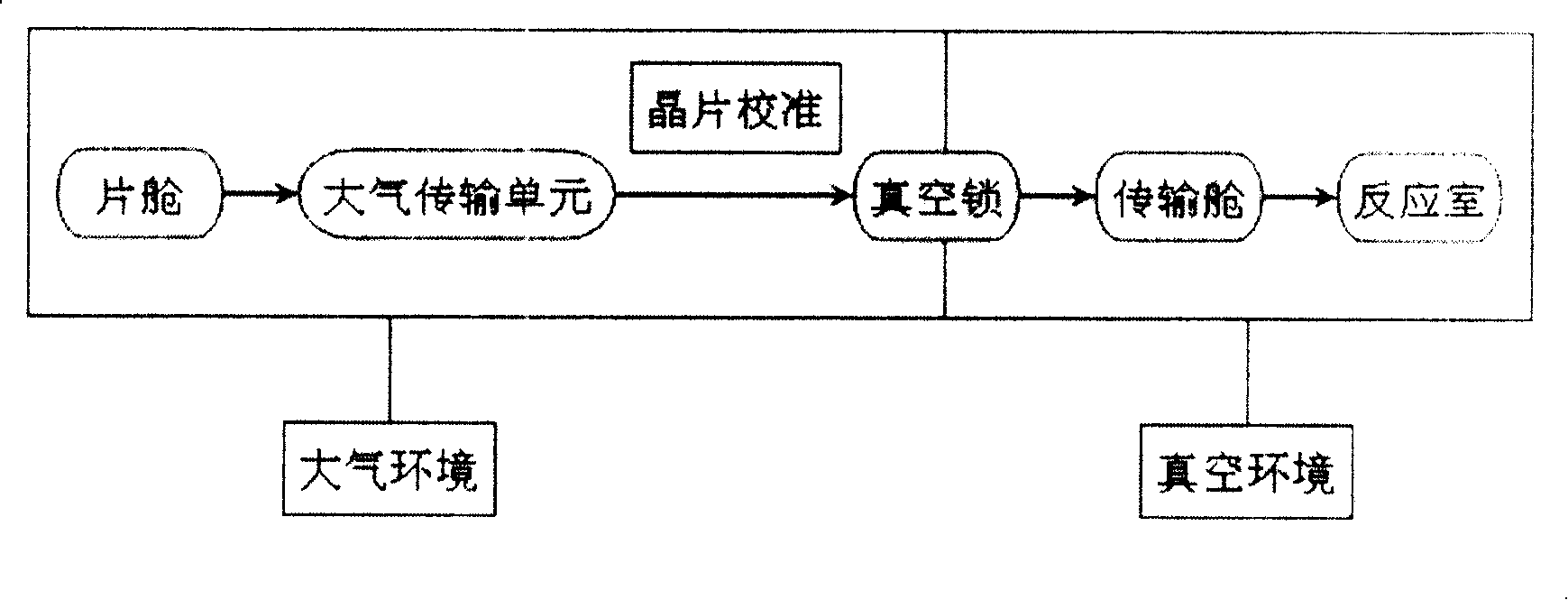

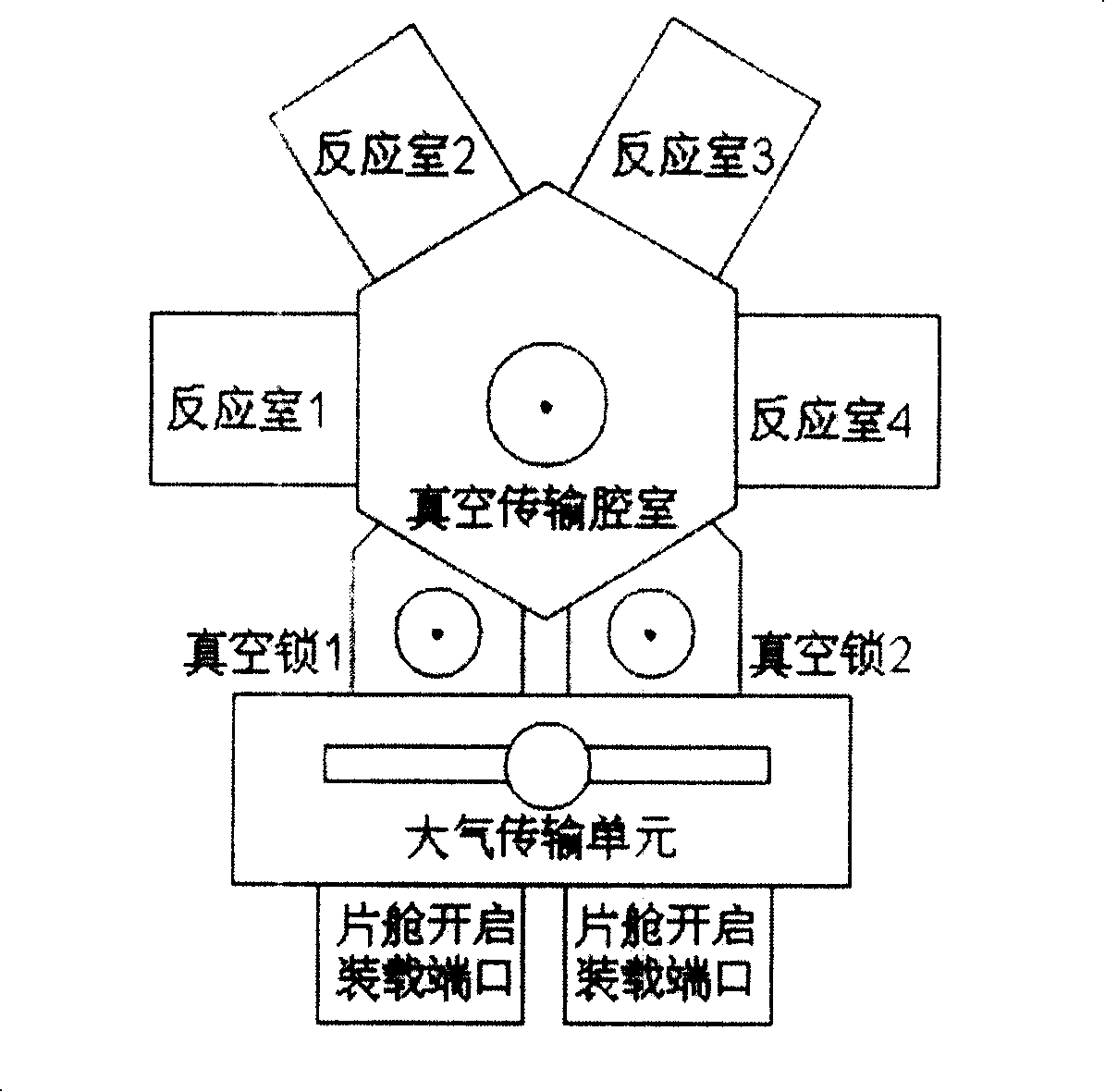

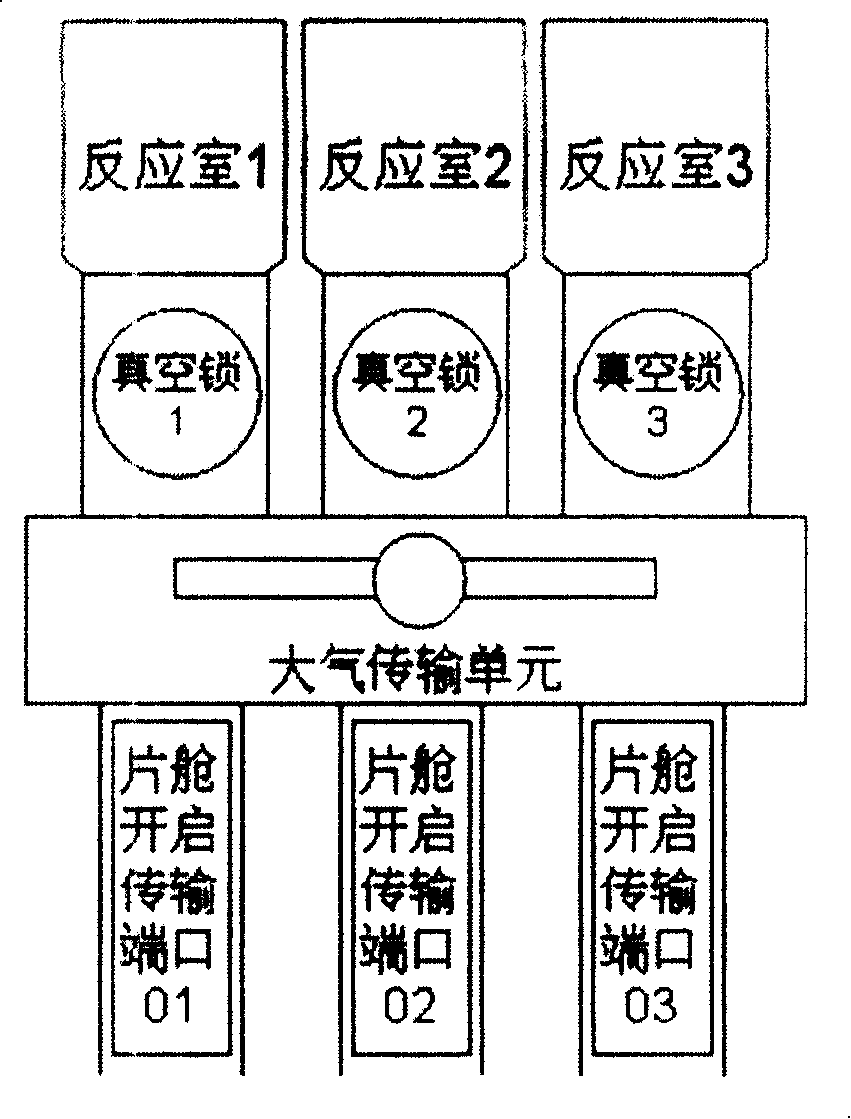

Vacuum lock transitional cavity

A technology of vacuum lock and transition cavity, which is applied in the field of microelectronics, can solve the problems of poor control of the cleanliness of the vacuum lock chamber, low output rate, and impact on output rate, etc., to achieve good adjustability and good cleanliness , the effect of increasing the output rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

[0023] Such as Figure 5 Shown, when the present invention is carried out, comprise chamber 5, the inflation system 1 on the chamber and the air extraction system 2, the valve A, B of chamber end, also be provided with wafer supporting device 7, in described chamber 5, The base 6, wherein the bottom of the supporting device 7 is connected to the base 6.

[0024] Such as Figure 5 As shown, the present invention adopts a four-layer wafer supporting device 7, which can exchange 4 wafers during one filling and pumping process of the vacuum lock transition chamber. According to the SEMI standard (semiconductor industry standard), the height of the 300mm wafer transmission opening is 50mm, and the spacing between each layer of wafers is also stipulated as 10mm. In this way, in the vacuum lock transition chamber, four layers of wafers can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com