Installation for supporting half floating stock tank in shipborne water cusion type

A supporting device and semi-floating technology, which is applied in the container discharge method, container filling method, gas/liquid distribution and storage, etc., can solve the problems of large concentrated stress on the hull and storage tank, excessive stress on the hull and storage tank, etc. Achieve the effect of reducing the possibility of fatigue damage, improving service life and uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

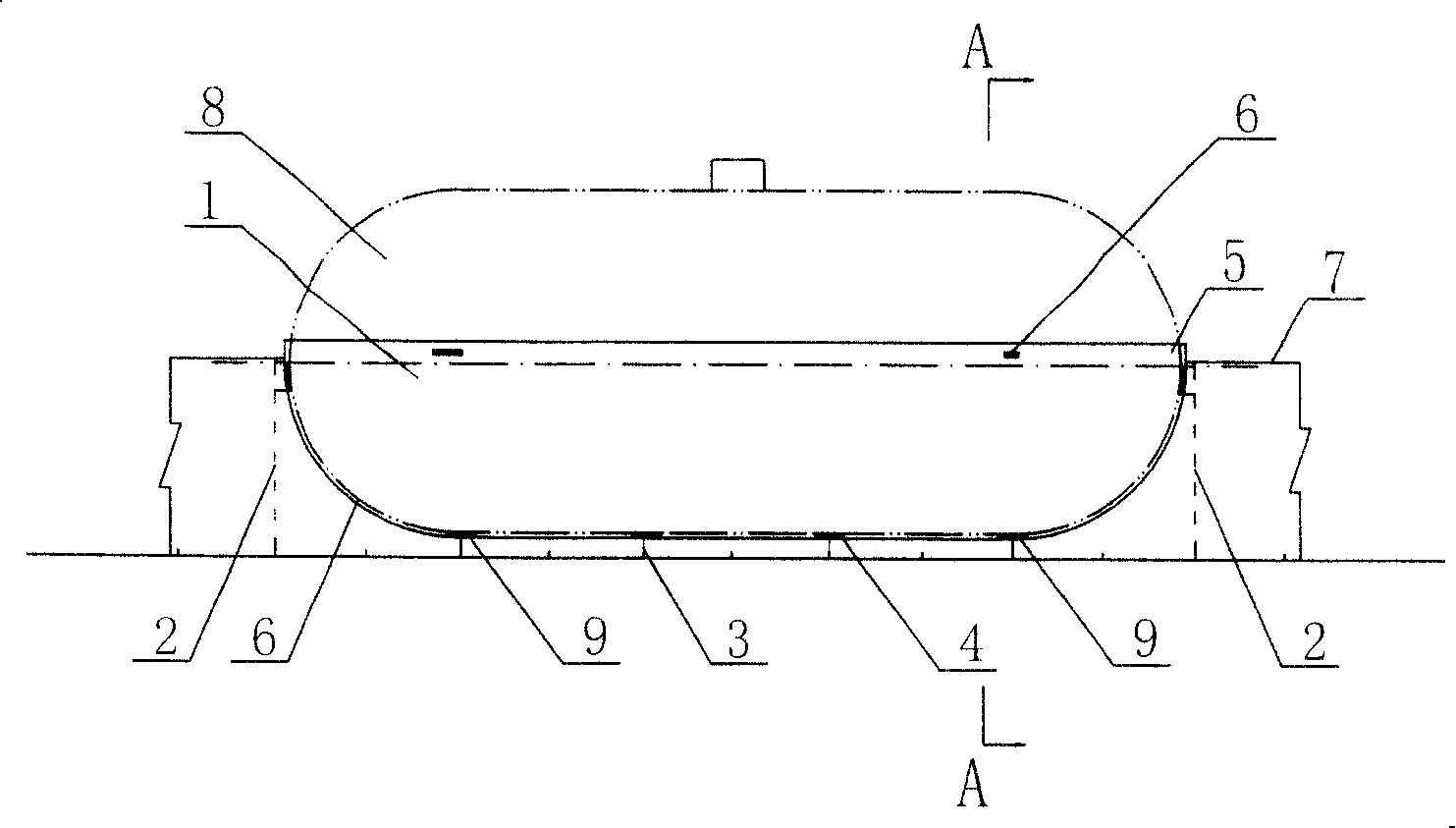

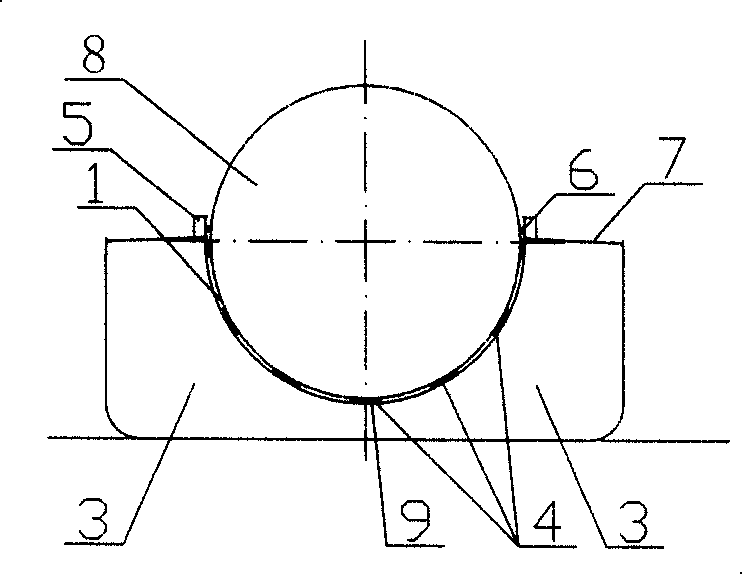

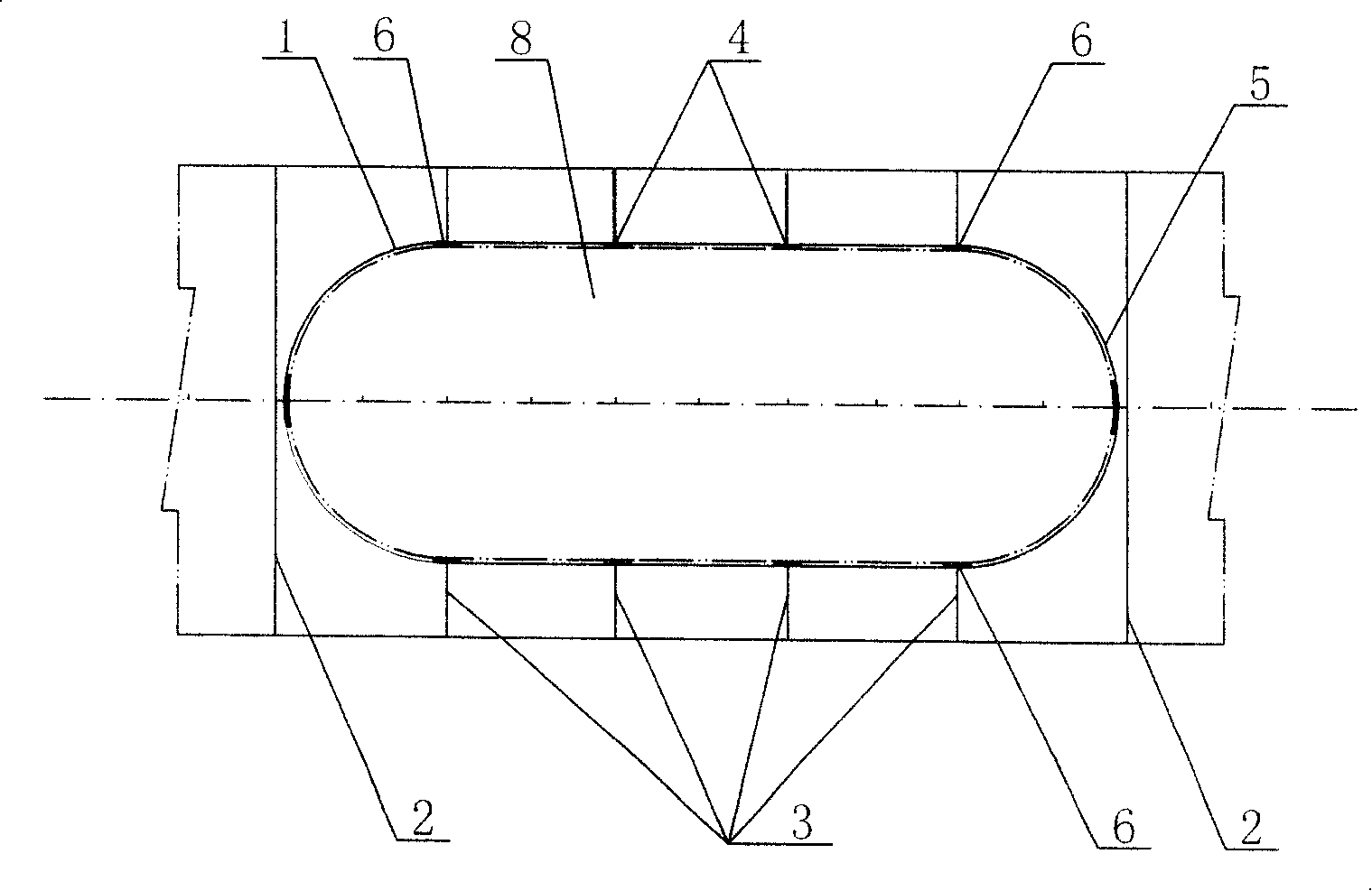

[0020] A concave watertight water jacket 1 is set on the hull deck. The cavity of the water jacket coincides with the longitudinal lower half section of the storage tank 8. The middle is semi-cylindrical or over half-cylindrical, and the two ends are 1 / 4 spherical or over 1 / 4 Spherical shape, the inner diameter of the water jacket is slightly larger than the outer diameter of the storage tank, usually 50-100 mm larger, and the upper edge of the junction of the water jacket cavity and the hull deck 7 is provided with a water-retaining edge 5 that protrudes upwards and is higher than the hull deck surface. The water edge is integrated with the hatch fence; in addition, the two ends of the water jacket cavity can also be ellipsoidal, dish-shaped or plane-shaped for the convex heads at both ends of the storage tank; elastic pads are set in the water jacket ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com