Preparation method of high-purity multi-wall carbon nano-tube

A technology of multi-walled carbon nanotubes and nitrogen atmosphere, applied in the direction of nanostructure manufacturing, nanotechnology, nanotechnology, etc., can solve the problems of high price, high toxicity of carbon source material benzene, etc., and achieve low cost, excellent preparation process and equipment Simple, easy-to-achieve effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Step 1 Mix 1.5g of activated carbon with 3g of ferrocene and grind them evenly;

[0016] Step 2 spread the mixture obtained in step 1 in a quartz crucible, and put it into a constant temperature zone in a tubular heating furnace;

[0017] In step 3, under the protection of a nitrogen flow rate of 300ml / min, the furnace temperature was raised to 1000°C at a rate of 15°C / min, reacted at this temperature for 3 hours, and cooled to 25°C under the protection of a nitrogen atmosphere to obtain multi-walled carbon nano tube, the product yield was 0.7 g.

Embodiment 2

[0019] Step 1 and step 2 are identical with embodiment one;

[0020] In step 3, under the protection of a nitrogen flow rate of 100ml / min, the temperature is raised to 1000°C, reacted at this temperature for 3 hours, and cooled to 25°C under the protection of a nitrogen atmosphere, and the product obtained is multi-walled carbon nanotubes, and the product yield is 0.5g .

[0021] In an embodiment, the mixture obtained in step 1 can also be spread in a silicon carbide crucible or a corundum crucible.

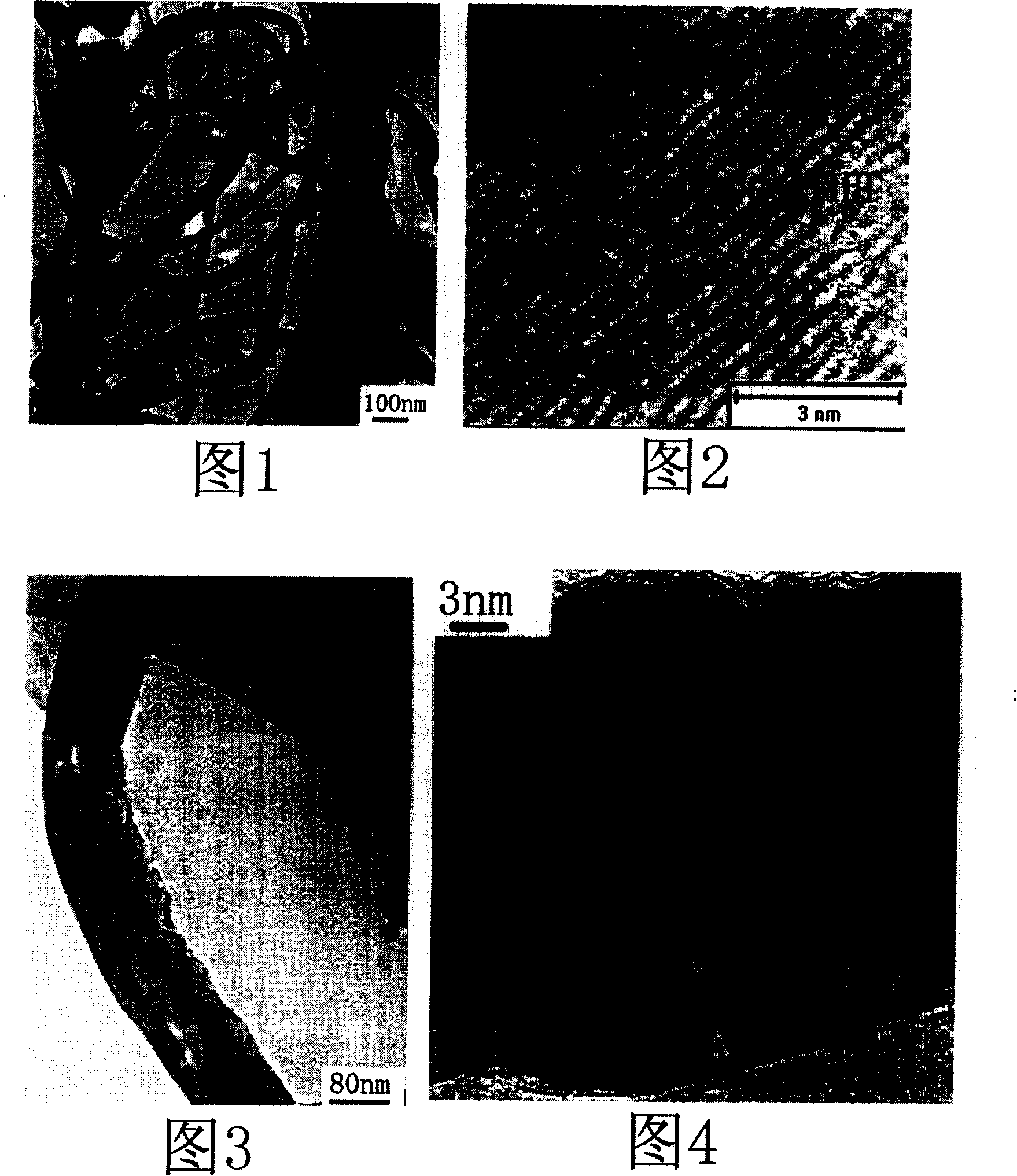

[0022] Fig. 1 and Fig. 3 are respectively the typical transmission electron micrographs of the multi-walled carbon nanotubes prepared by the present invention in the first embodiment and the second embodiment; as can be seen from the figure, the prepared multi-walled carbon nanotubes have high purity and small tube diameter. Uniform, with an inner diameter of 15-25nm, an outer diameter of 40-60nm, and a length of hundreds of nanometers to microns. From Fig. 2 and Fig. 4, it is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com