Off-the-road tire and iss production method

一种工程车轮胎、制造方法的技术,应用在工程车轮胎领域,能够解决区块碎裂、胎面早期磨耗等问题,达到兼顾耐发热性、兼顾耐磨耗性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0089] The OTR tires of the present invention were produced, and performance evaluations related to wear resistance, crack progression resistance, heat release performance, and traction performance were performed as described below.

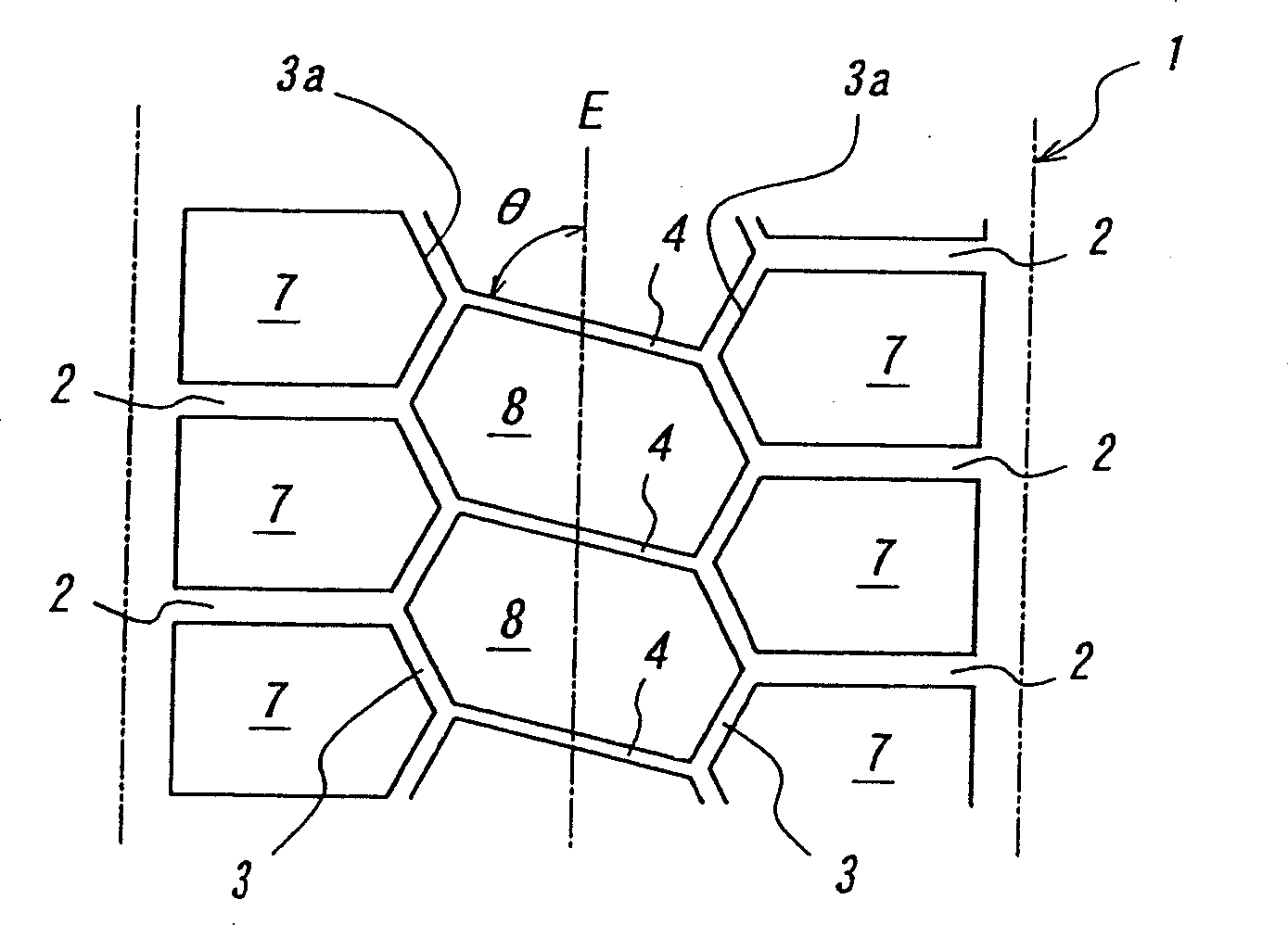

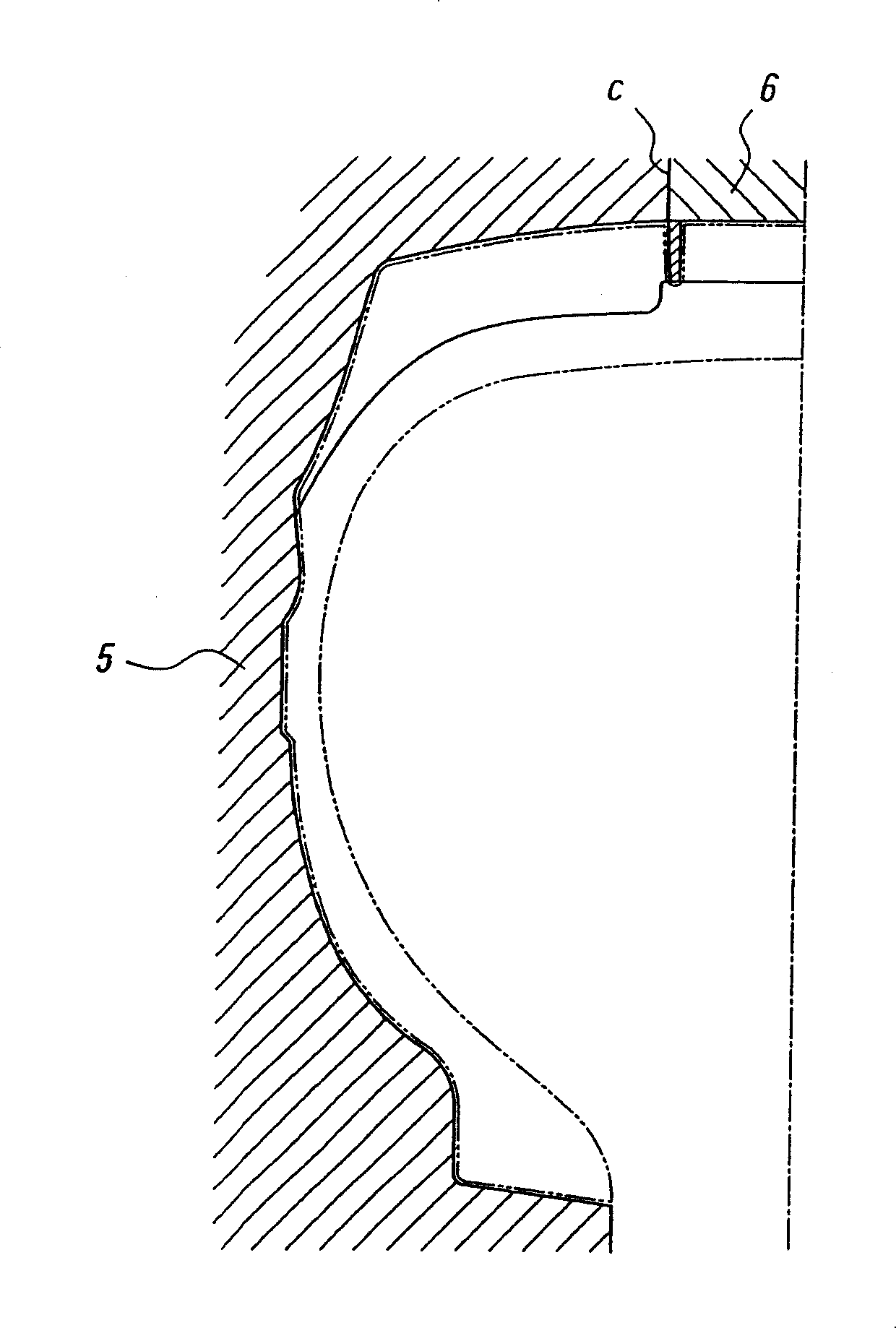

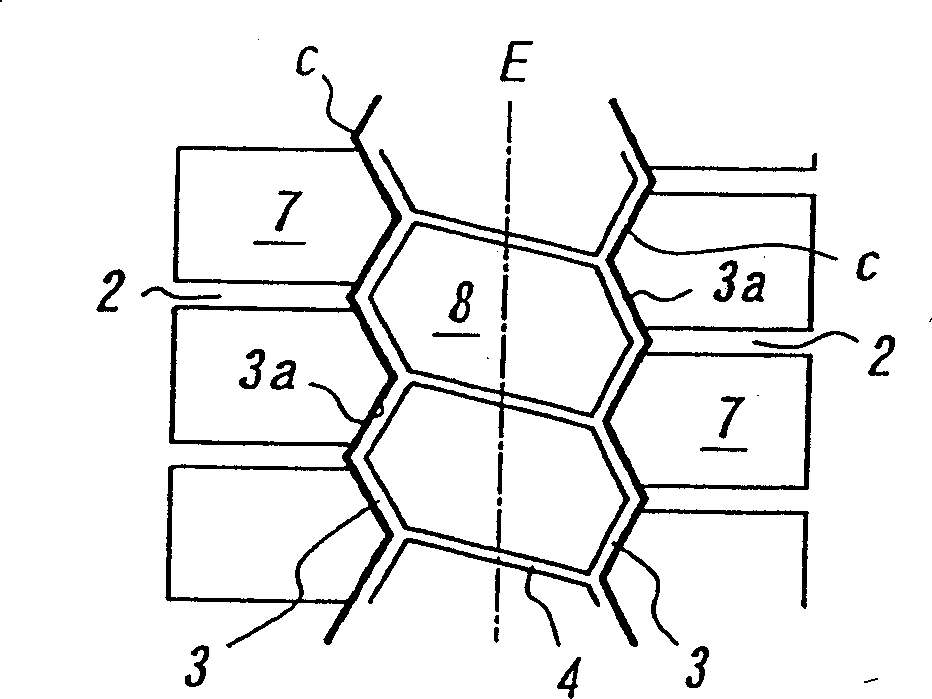

[0090] Example tire 1 has figure 1 With the tread pattern shown, Example tire 2 has the following Figure 4 With the tread pattern shown, the previous example tire 1 has Figure 8 The tread pattern shown, then the previous example tire 2 has the following Figure 9 Tread pattern shown, and embodiment tire 3 has the groove structure as shown in Figure 5, embodiment tire 4 has the groove structure as shown in Figure 5 and Figure 6, then embodiment tire 5 has the groove structure as shown in Figure 5, Figure 6 6 and the trench structure shown in Figure 7.

[0091] Furthermore, each of the test tires had the specifications shown in Table 1, and the region from the bead portion to the sidewall portion had the same structure as that of an engineerin...

Embodiment 2

[0105] Find the cost of the mold when changing the type of mold and the boundary position of the mold parts, the exchange time of the separated mold parts, and measure the occurrence of the boundary position of the mold parts of the tire when the manufactured tire is rotated at a speed of 10km / h for 5000km The partial wear of the land part caused by the overflow rubber, the results are shown in Table 3.

[0106] Also, the tire size and usage conditions at this time are the same as those in Example 1.

[0107]

[0108] According to Table 3, no matter in any embodiment, the disadvantage in terms of mold cost can be achieved by separating the interchangeability of mold parts, and smooth removal of vulcanized tires can be achieved, and in particular , Embodiments 1, 2 and 6 can effectively avoid partial wear caused by the presence of spilled rubber.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com