Heavy-load pneumatic tire

A pneumatic tire and tire technology, which is applied in the field of tread patterns to prevent wet grip performance and block defects, improve snow driving performance and handling stability, and improve traction and handling stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

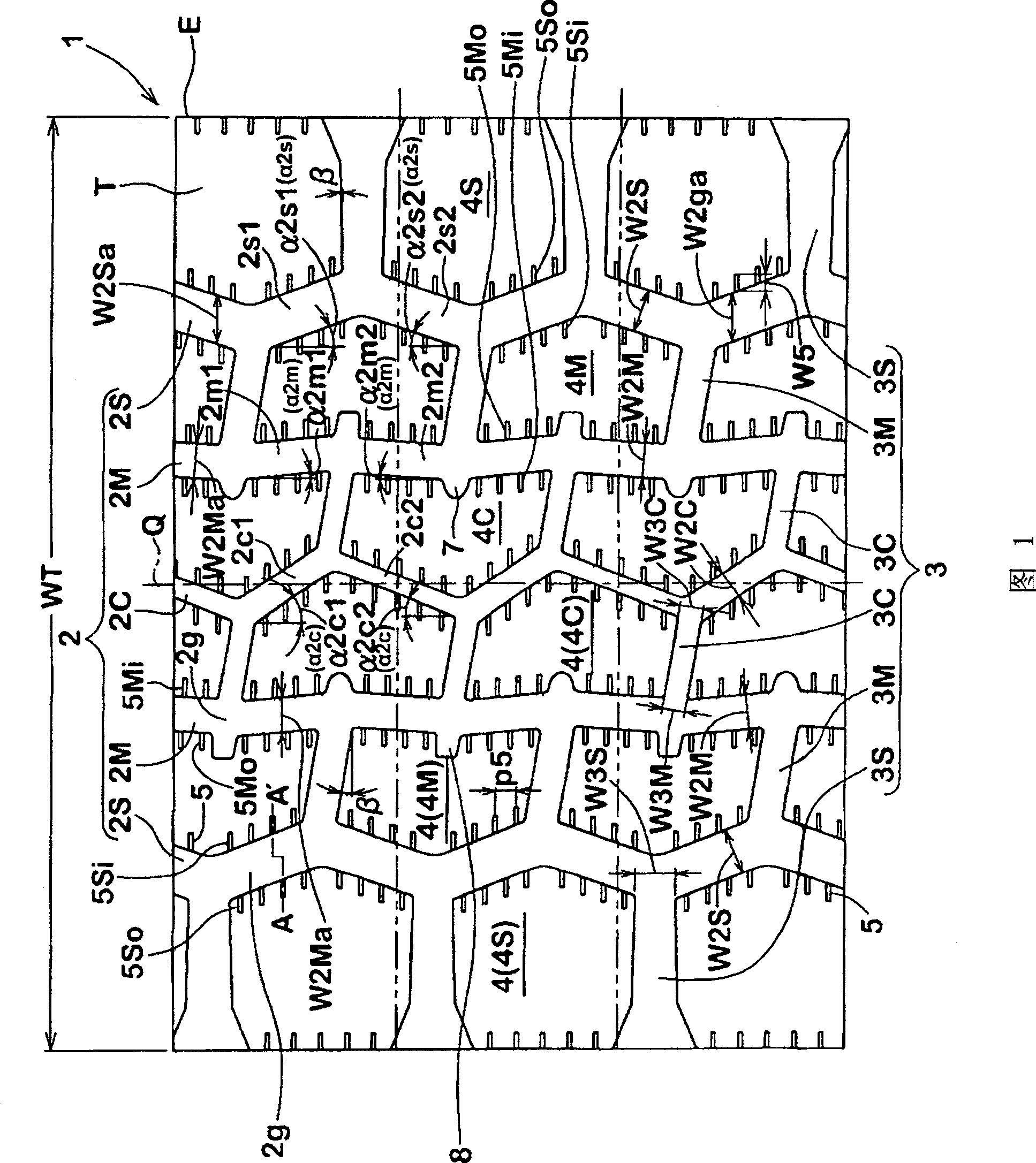

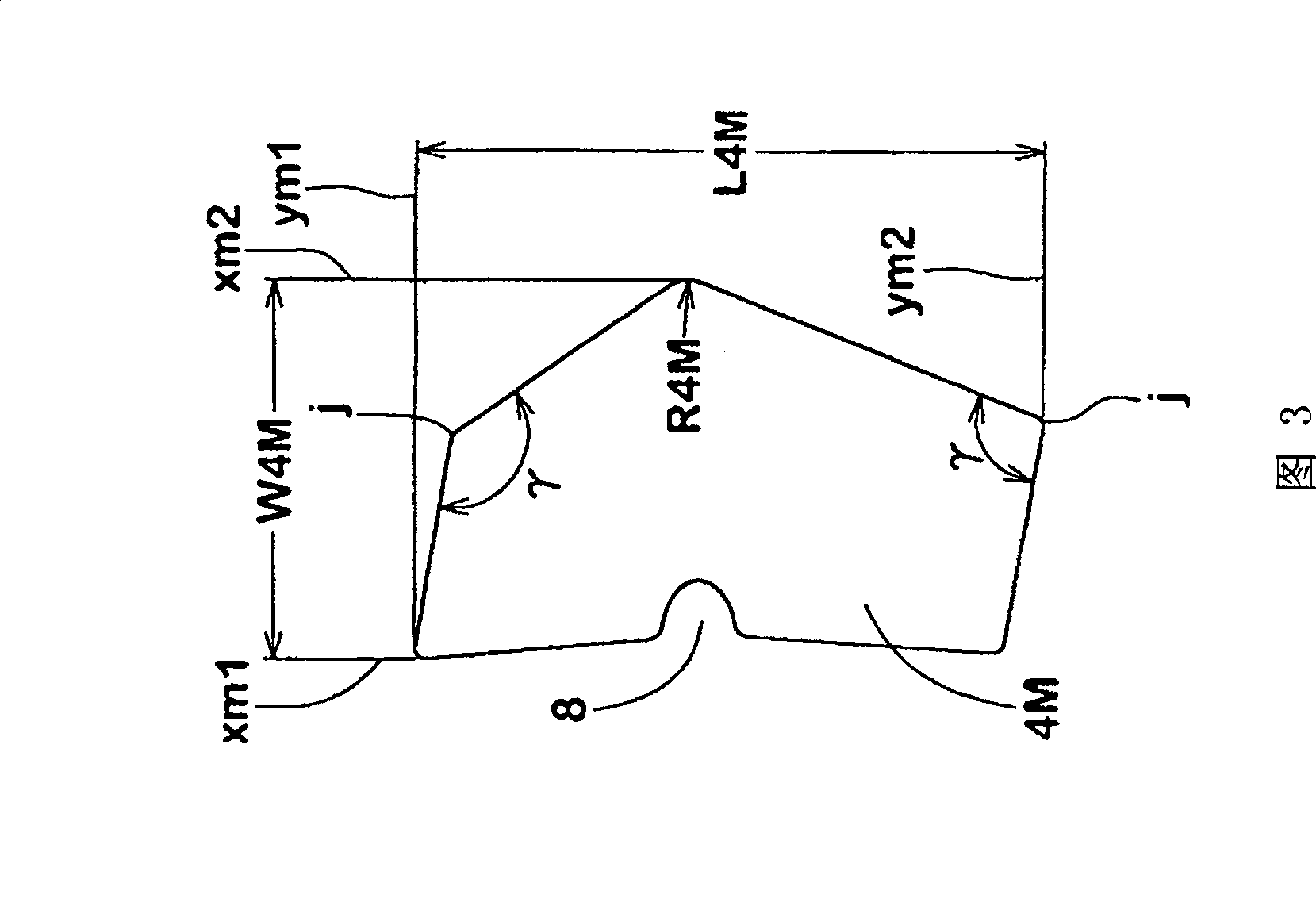

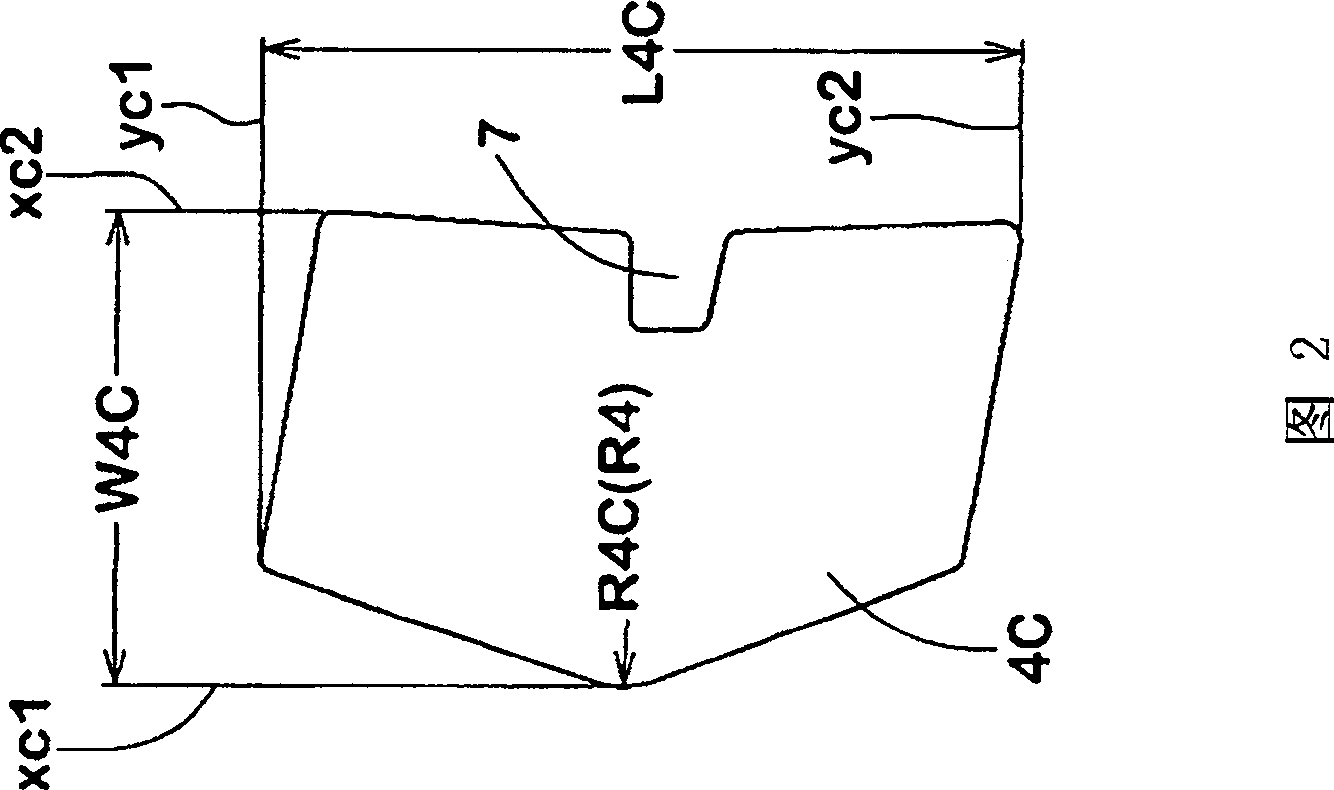

[0039] Hereinafter, an embodiment of the present invention will be described based on the drawings. FIG. 1 is a plan view showing a tread pattern of a tread portion of a heavy-duty pneumatic tire (hereinafter simply referred to as tire) 1 according to the present invention, which is planarly developed. The tread T between the tread edges E, E of the tire 1 is formed by one or more radii of curvature in a section including the tire axis. Further, the tread T is divided into blocks 4 by providing a plurality of longitudinal grooves 2 extending in the tire circumferential direction and a plurality of lateral grooves 3 extending in a direction intersecting the longitudinal grooves 2 . On the side or both sides of the ditch wall facing the vertical ditch whose groove width W2 is the widest or the second widest in the direction perpendicular to the ditch center line, a wall ditch 5 extending along the depth direction is arranged and set as a band Groove vertical groove 2g, to achie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com