Motor-free wheel mechanism driven by shape memory alloy

A memory alloy and motor-less technology, which is applied to mechanisms that generate mechanical power, machines/engines, mechanical equipment, etc., can solve problems such as large volume, small volume, and complex structure of the driving mechanism, so as to reduce complexity, overcome space and effect of weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

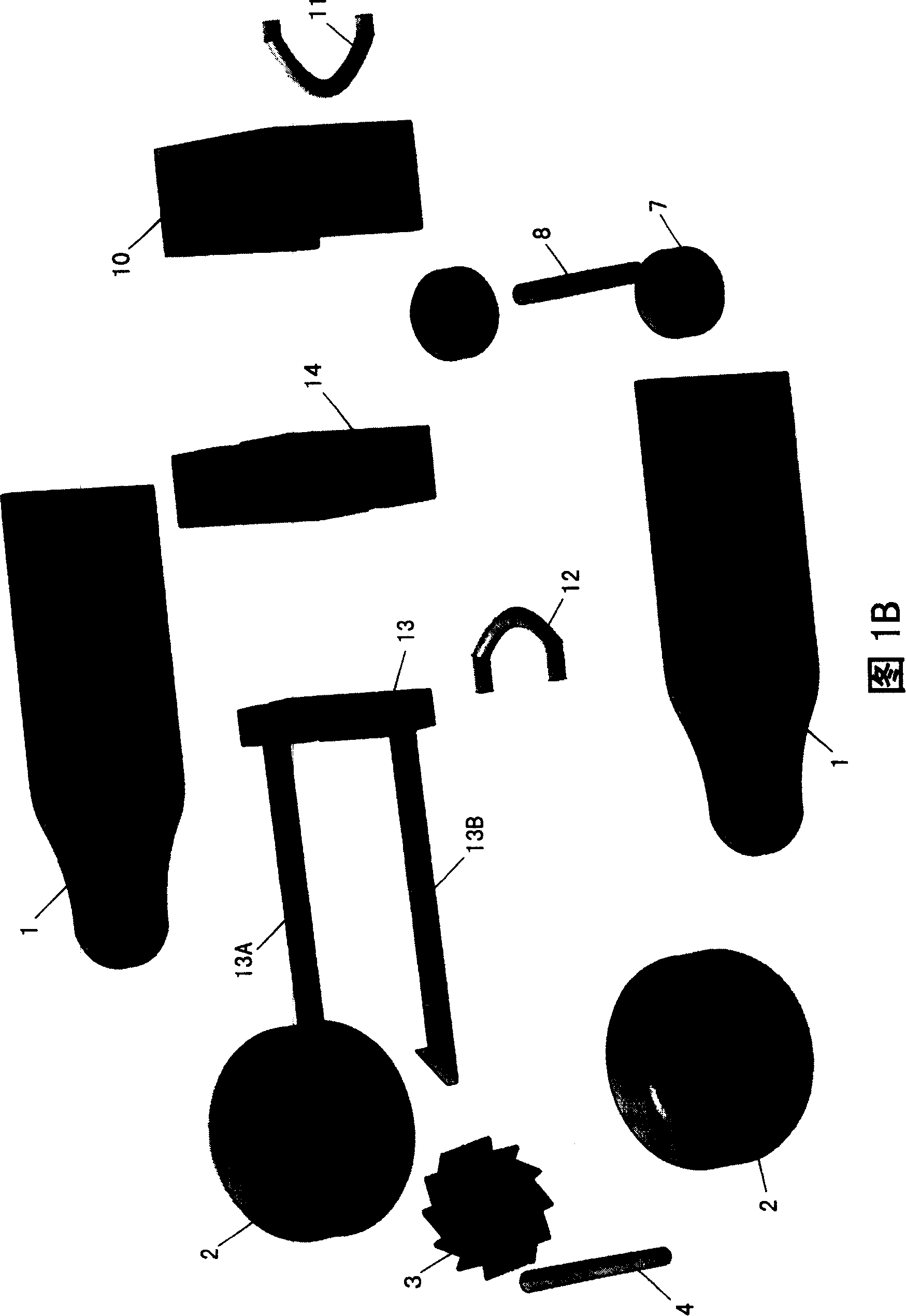

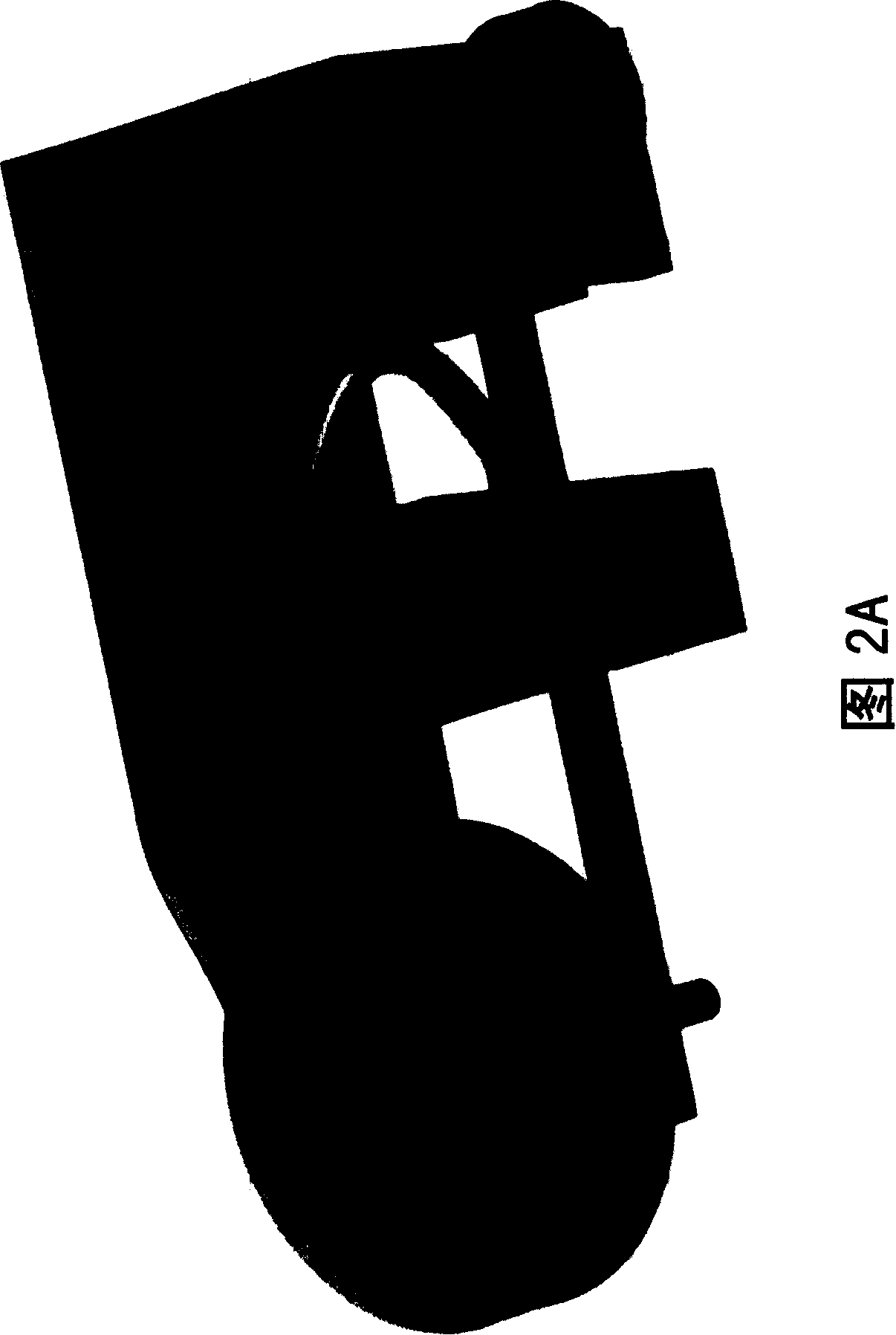

[0035] FIG. 1A shows a schematic perspective view of the motorless wheel mechanism of the present invention; FIG. 1B shows an exploded schematic view of the main components of the motorless wheel mechanism of the present invention. Figure 2A is a perspective view of the motorless wheel mechanism of the present invention in its initial state, with one side plate and one driven wheel removed for clarity. Figure 2B is a perspective view of the motorless wheel mechanism of the present invention in its initial state, with one side plate, one driven wheel and end plates removed for clarity. In the figure, the direction to the left is the rear, and the direction to the right is the front.

[0036] The motorless wheel mechanism mainly includes three parts: a main body frame, a rotating part and a moving part. Wherein, the main frame forms an accommodating space, which is composed of two side plates 1, an end plate 10 and a support frame 14, and two driven wheels 7 are also arranged o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com