Galette unit

A godet roller and filament technology, applied in bearing components, bearing cooling, mechanical equipment, etc., can solve the problem of aggravating the temperature difference between the inner ring and outer ring of the rolling bearing, and achieve the purpose of increasing the heat dissipation surface, uniform and continuous heat and heat dissipation, The effect of fast heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

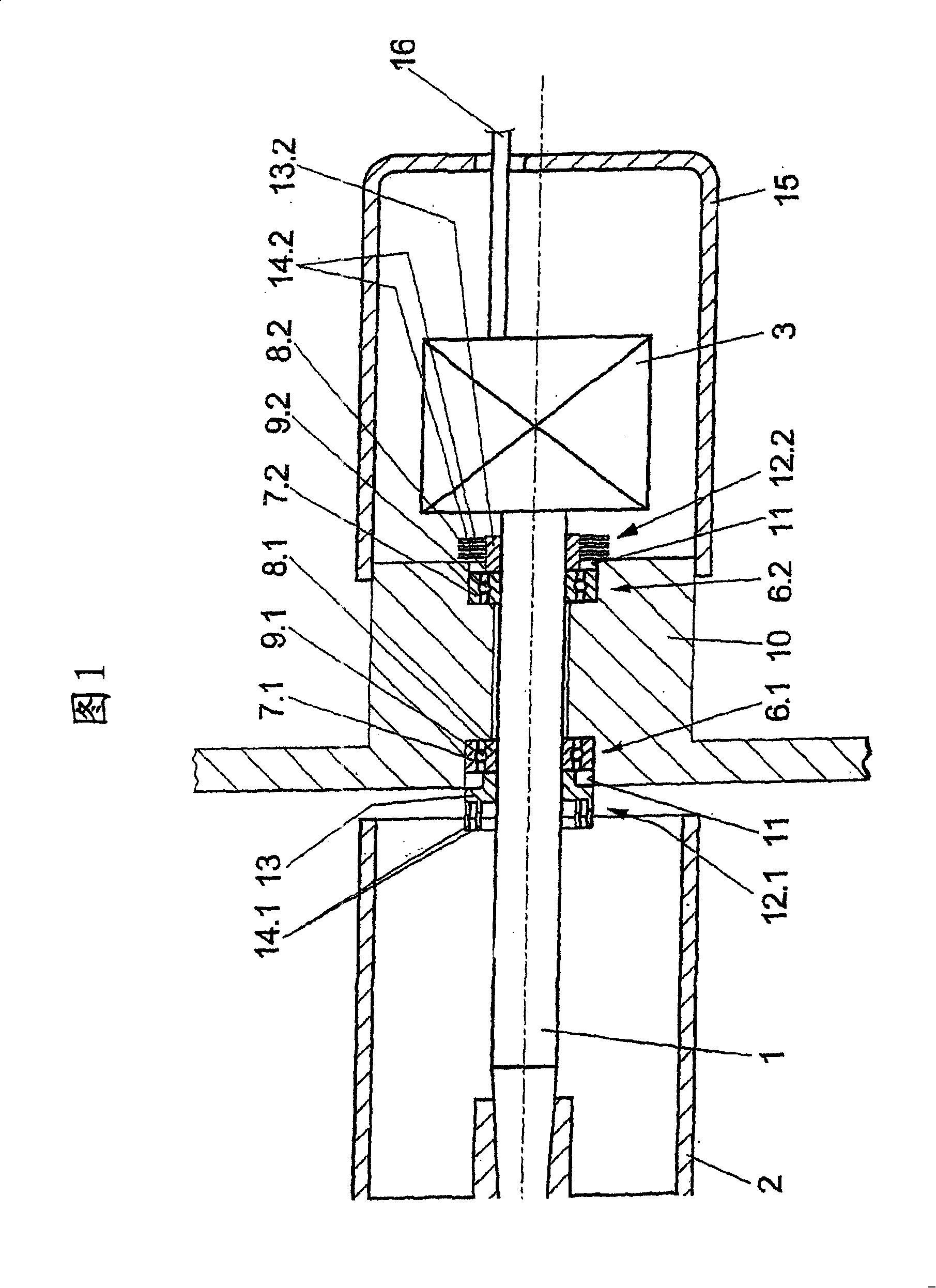

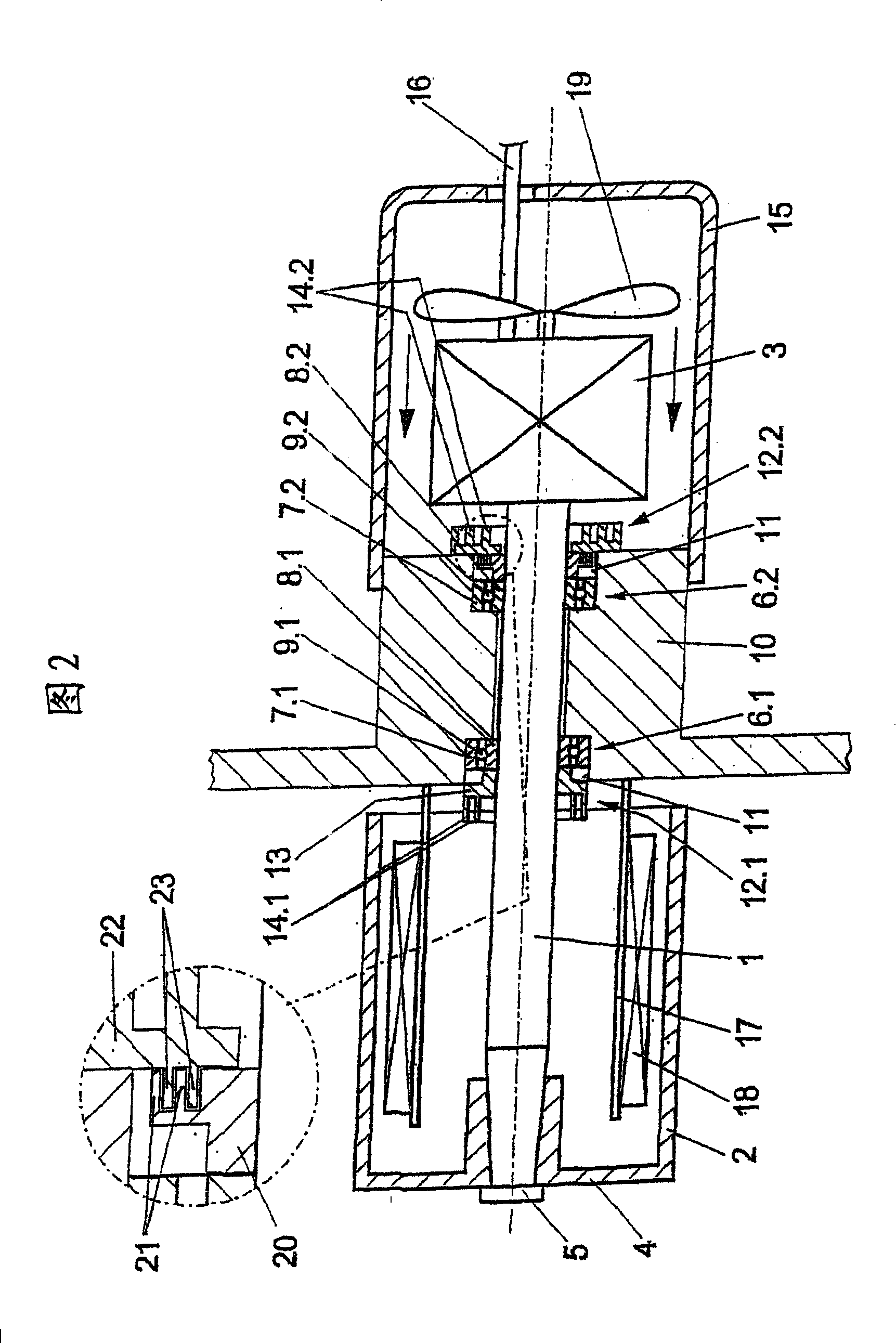

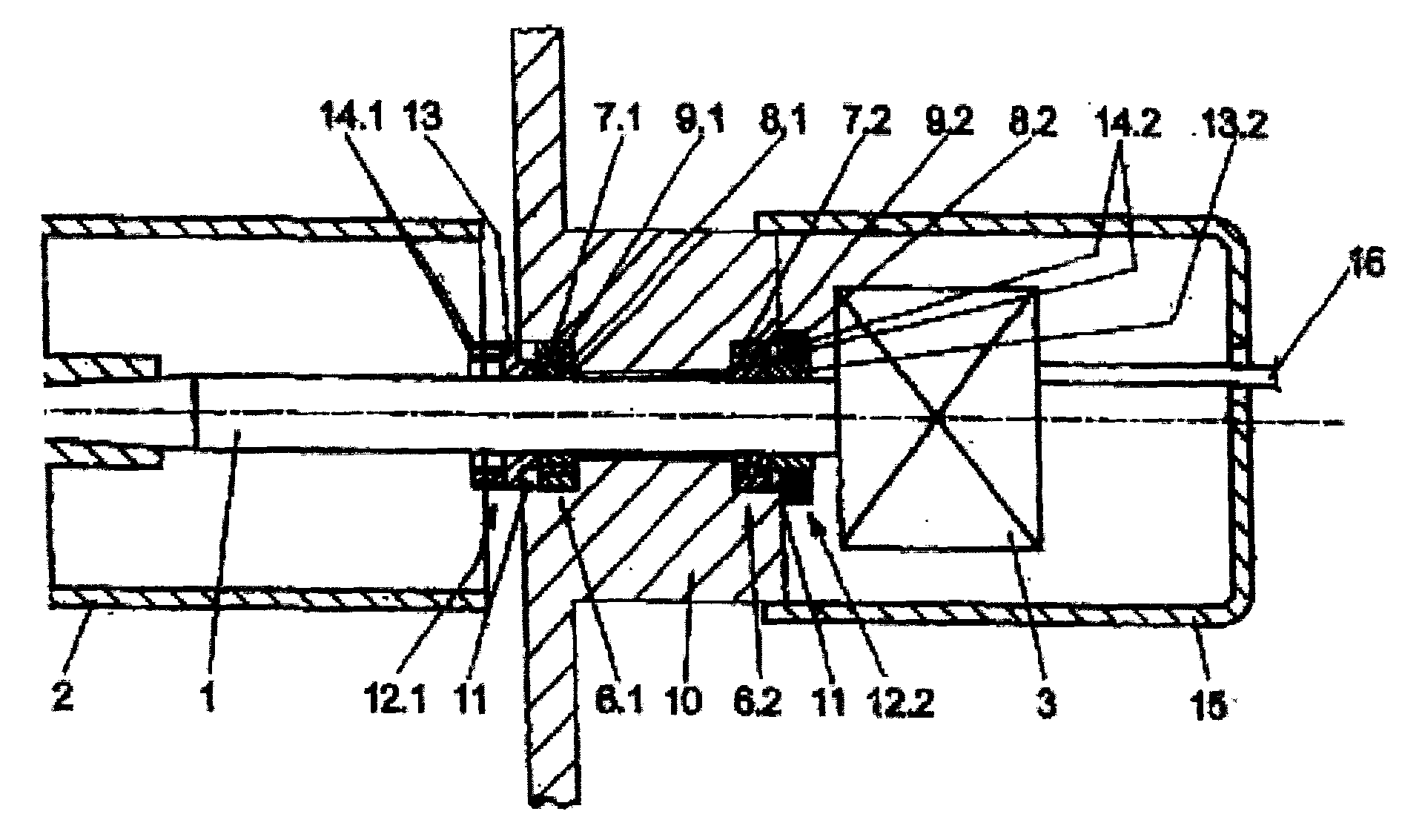

[0023] 1 schematically shows a longitudinal section through a godet unit according to the invention. The godet unit consists of a godet casing 2 . Godet roll cover 2 is made into pot shape, and is enclosed within on a driving shaft 1. The protruding end of the drive shaft 1 is rotationally fixedly connected with the end wall 4 of the godet roller casing 2 . The godet jacket 2 is here fixed on the drive shaft 1 by means of a clamping element 5 . At the other end of the drive shaft 1 the drive shaft 1 is connected to the drive 3 . The driving device 3 is made as a motor here, and it drives the drive shaft 1 and the godet roller overcoat 2 .

[0024] In the area between the godet housing 2 and the drive 3 the drive shaft is supported by two first rolling bearings 6.1 and second rolling bearings 6.2 which are arranged at a distance from one another. For this purpose, a bearing bore 11 is respectively machined into a bearing 10 through which the drive shaft 1 passes, in which b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com