A method for welding aluminum bus bars outdoors in a cold environment

An aluminum busbar and environmental technology, applied in the direction of welding equipment, welding medium, welding equipment, etc., to achieve the effect of promoting self-propagating reaction, stable reaction and improving welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

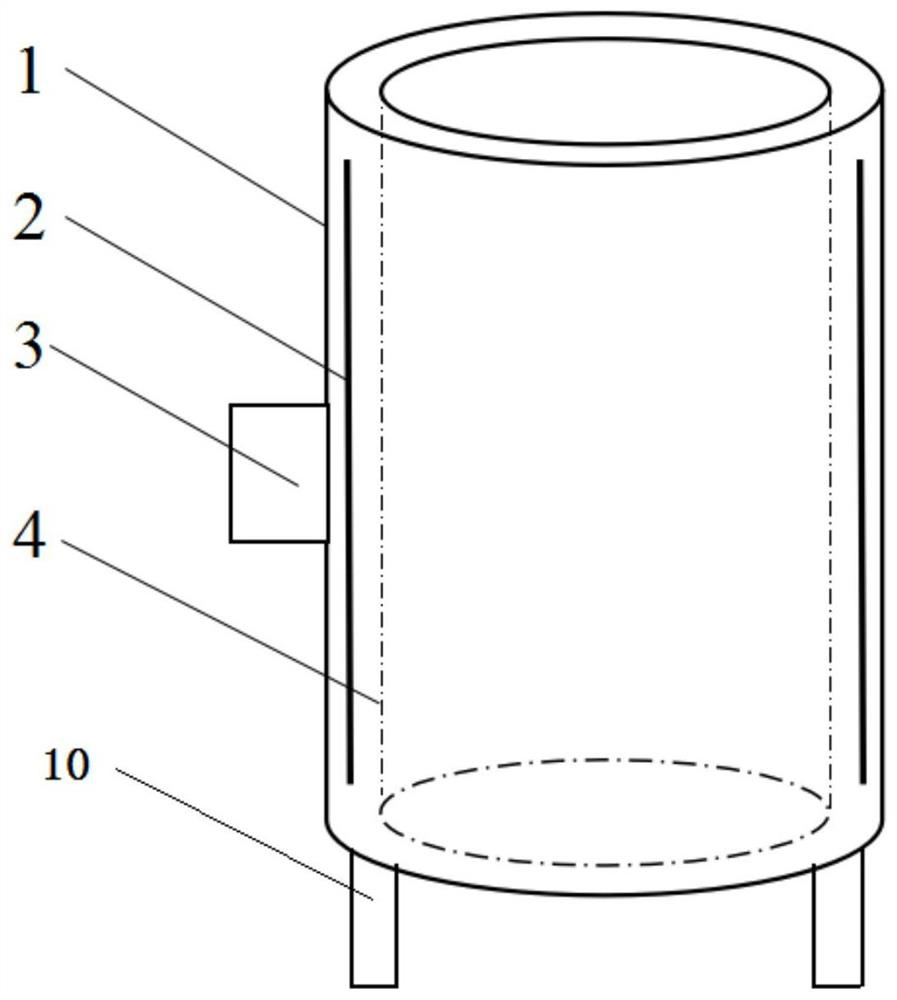

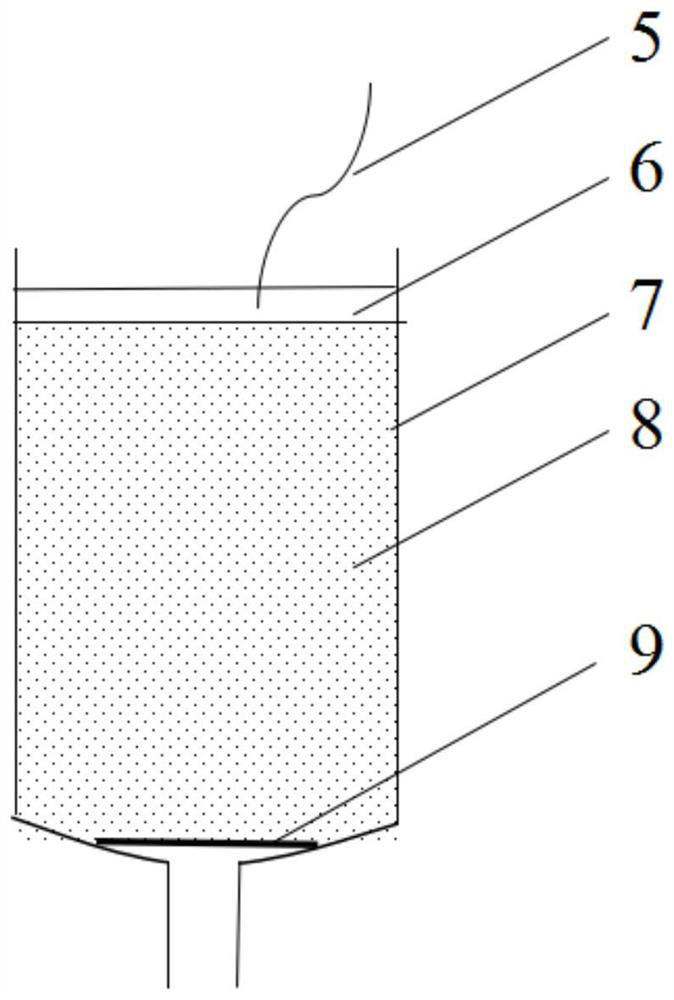

[0042] Perform outdoor welding in an environment with an outdoor temperature of 5°C. Clean the cross-section of the aluminum busbar to be welded, and then place a base with a suitable height under the aluminum busbar to be welded and make the parts of the aluminum busbar to be welded close together. prepare a figure 2 The shown through-hole graphite crucible 7 has a diameter of 0.2-1 m, which is placed above the aluminum busbar. Attach the baffle 9 to the internal through hole of the graphite crucible 7, and then add 37% aluminum powder, 32% tin oxide, 6% aluminum-copper alloy, 2% magnesium oxide, 14% zinc sulfate, 1% boron powder, Self-propagating flux with 3% silicon fume and 5% calcium fluoride8. Stir it evenly after checking that there is no powder leakage phenomenon, spread a layer of gunpowder powder 6 on the surface of the flux and insert a lead wire 5 for ignition in the powder. will be like figure 1 The resistance wire heating equipment is placed on the periphery...

Embodiment 2

[0044] Perform outdoor welding in an environment where the outdoor temperature is -20°C. Clean the cross-section of the aluminum busbar to be welded, and then place a base with a suitable height under the aluminum busbar to be welded and make the parts of the aluminum busbar to be welded close together. prepare a figure 2 The shown through-hole graphite crucible 7 has a diameter of 0.2-1 m, which is placed above the aluminum busbar. Stick the baffle 9 on the inner through hole of the graphite crucible 7, and then add 35% aluminum powder, 33% tin oxide, 5% aluminum-copper alloy, 3% magnesium oxide, 13% zinc sulfate, 2% boron powder, Self-propagating flux with 4% silicon fume and 5% calcium fluoride8. Stir it evenly after checking that there is no powder leakage phenomenon, spread a layer of gunpowder powder 6 on the surface of the flux and insert a lead wire 5 for ignition in the powder. will be like figure 1 The resistance wire heating equipment is placed on the periphery...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com