Method for loading packaged cement

A technology of cement and chute, which is applied in the field of bagged cement loading devices, can solve the problems of large vibration of the walking belt, high labor intensity of workers, and influence on the progress of loading, and achieves the advantages of reduced manufacturing and installation costs, simple structure, and reduced labor intensity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

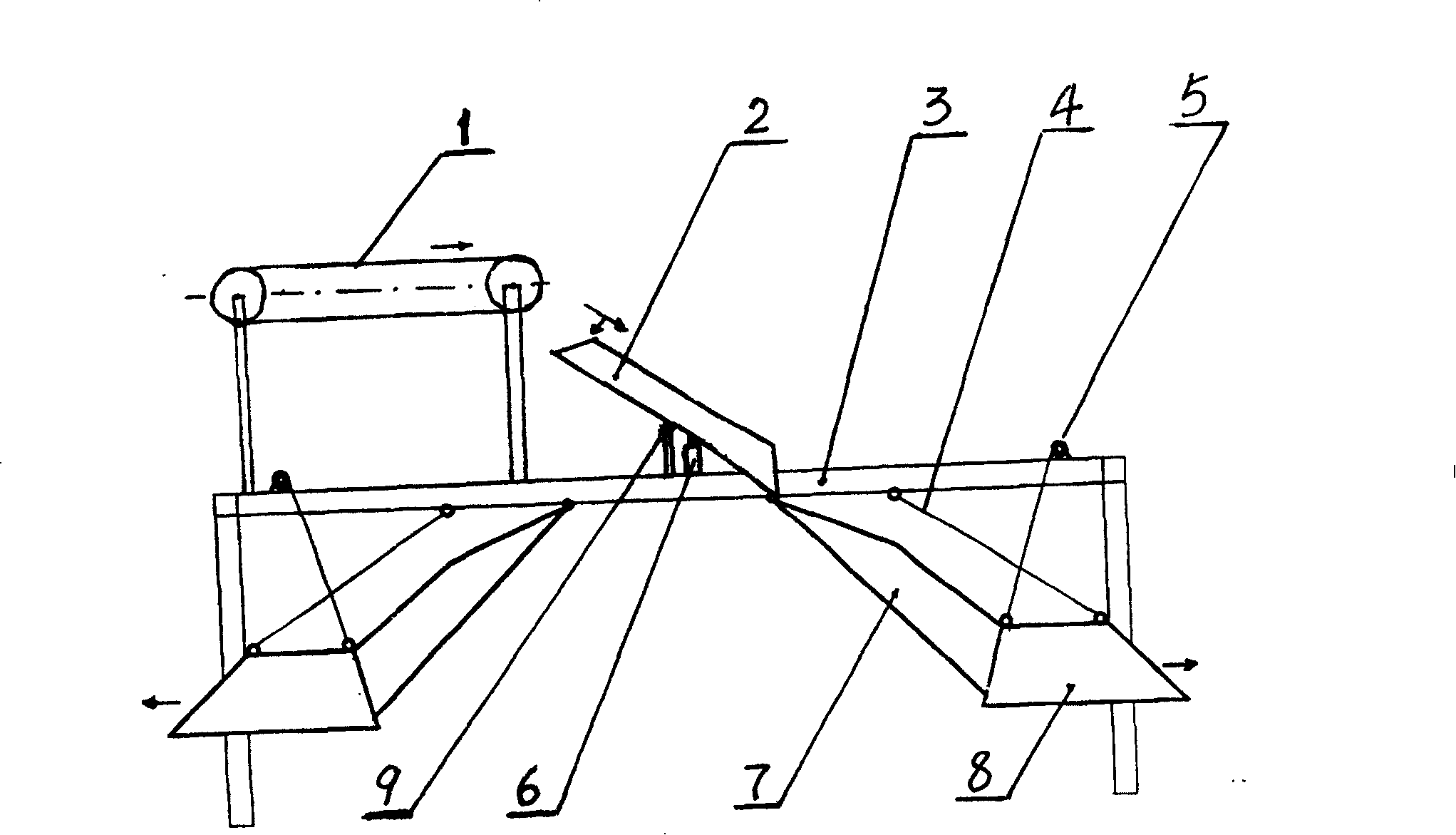

[0010] In conjunction with the accompanying drawings and embodiments, the specific structure of the bagged cement truck loading device of the present invention will be further described, and its features and advantages will be more clear.

[0011] The present invention creates the embodiment of bagged cement loading device, see figure 1 , The structure includes: a conveying mechanism, a reversing mechanism, two unloading mechanisms, and a rack. Wherein, the conveyor adopts the existing fixed belt conveyor 1, which can be horizontally (when the bagged cement directly falls on the belt conveyor from the packaging machine) or inclined (when the bagged cement does not directly fall from the packaging machine) The packaging machine automatically falls on the belt conveyor, such as the case of moving from the pile of cement bags) and the output end of the belt is correspondingly installed on the bracket above the reversing mechanism; Shaft 9, the flap control part. The flap shaft 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com