Pliers clamping plate sharp-nose full automatic bag clamping apparatus

A fully automatic, sharp-nosed technology, applied in packaging automatic control, packaging, packaging protection, etc., can solve the problems of vacuum judgment not being able to achieve high accuracy, long vacuum judgment detection time, increasing auxiliary time, etc., to reduce actions. Timing, good action effect, the effect of increasing the strength of the bag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

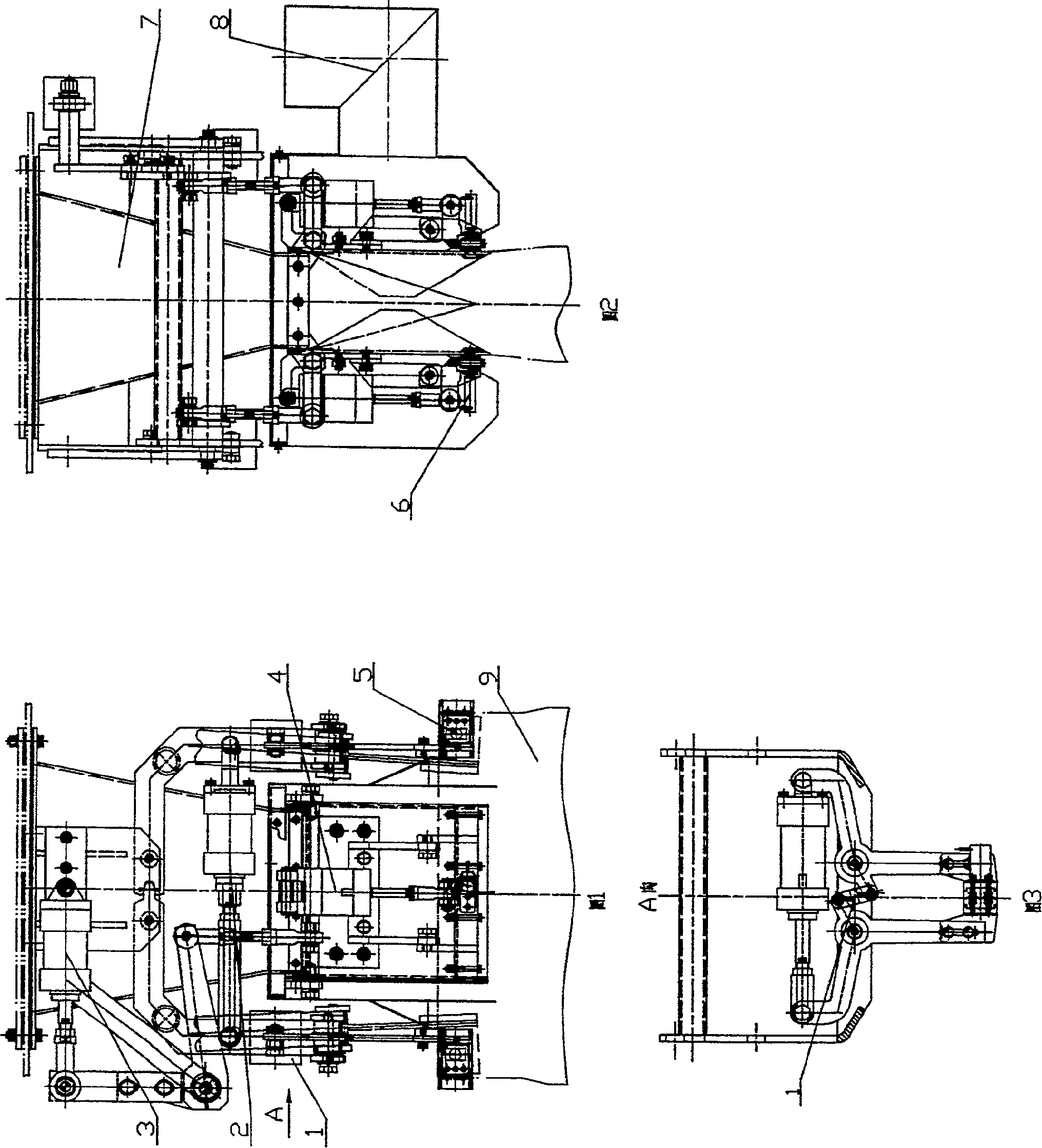

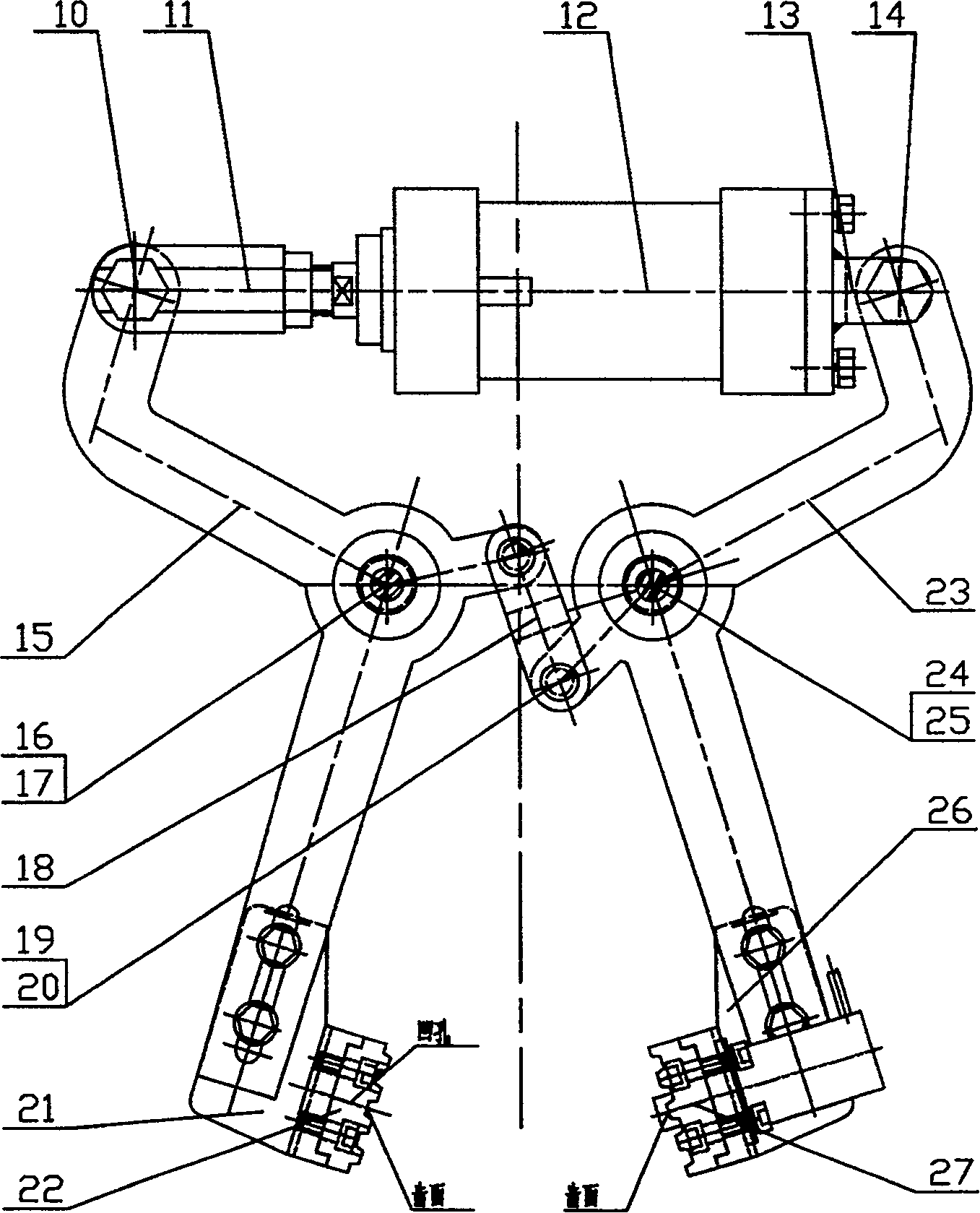

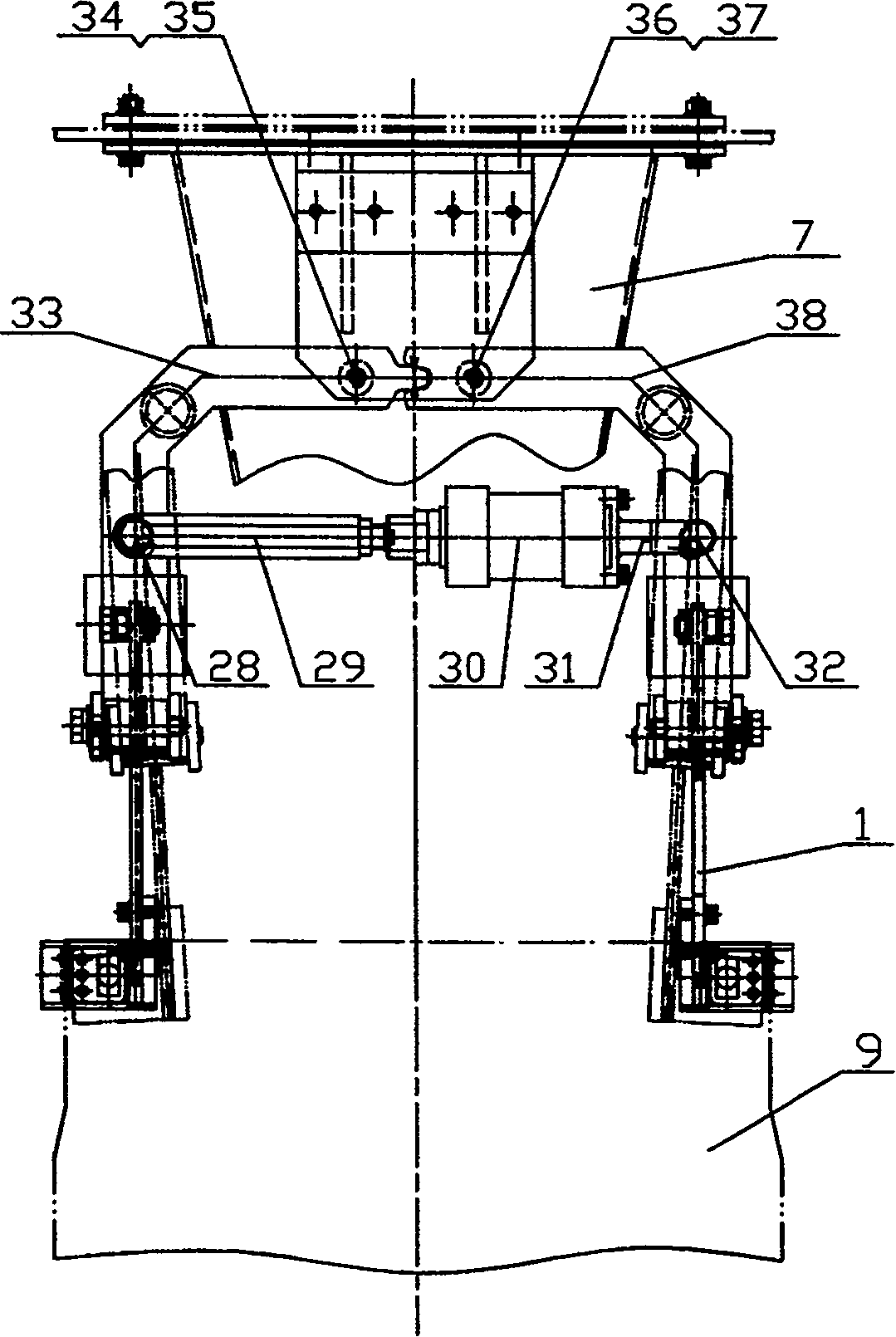

[0031] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

[0032]The present invention mainly consists of clamp bag clamping mechanism 1, clamp stretching and shrinking whole bag mechanism 2, feeding nozzle filling mechanism 3, plywood clamping bag mechanism 4, bag judging devices 5, 6, bag clamp body 7, and dust removal cover 8. Packaging bag 9, first bolt shaft 10, Y-shaped joint 11, clamp cylinder 12, double ear hanger 13, second bolt shaft 14, first support fork 15, third bolt shaft 16, first joint bearing 17. Connecting rod 18, sliding bearing 19, pin shaft 20, first clamp steel frame 21, first clamp teeth 22, second support fork 23, fourth bolt shaft 24, second joint bearing 25, second clamp Clamp steel frame 26, second clamp teeth 27, fifth bolt shaft 28, Y-shaped joint 29, stretching cylinder 30, double ear hanging feet 31, sixth bolt shaft 32, first swing frame 33, seventh bolt shaft 34. The third jo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com