Method of operating directly injecting diesel engine

A technology of diesel internal combustion engine and internal combustion engine, applied to internal combustion piston engine, combustion engine, fuel injection control and other directions, can solve problems such as poor starting ability and thermodynamic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

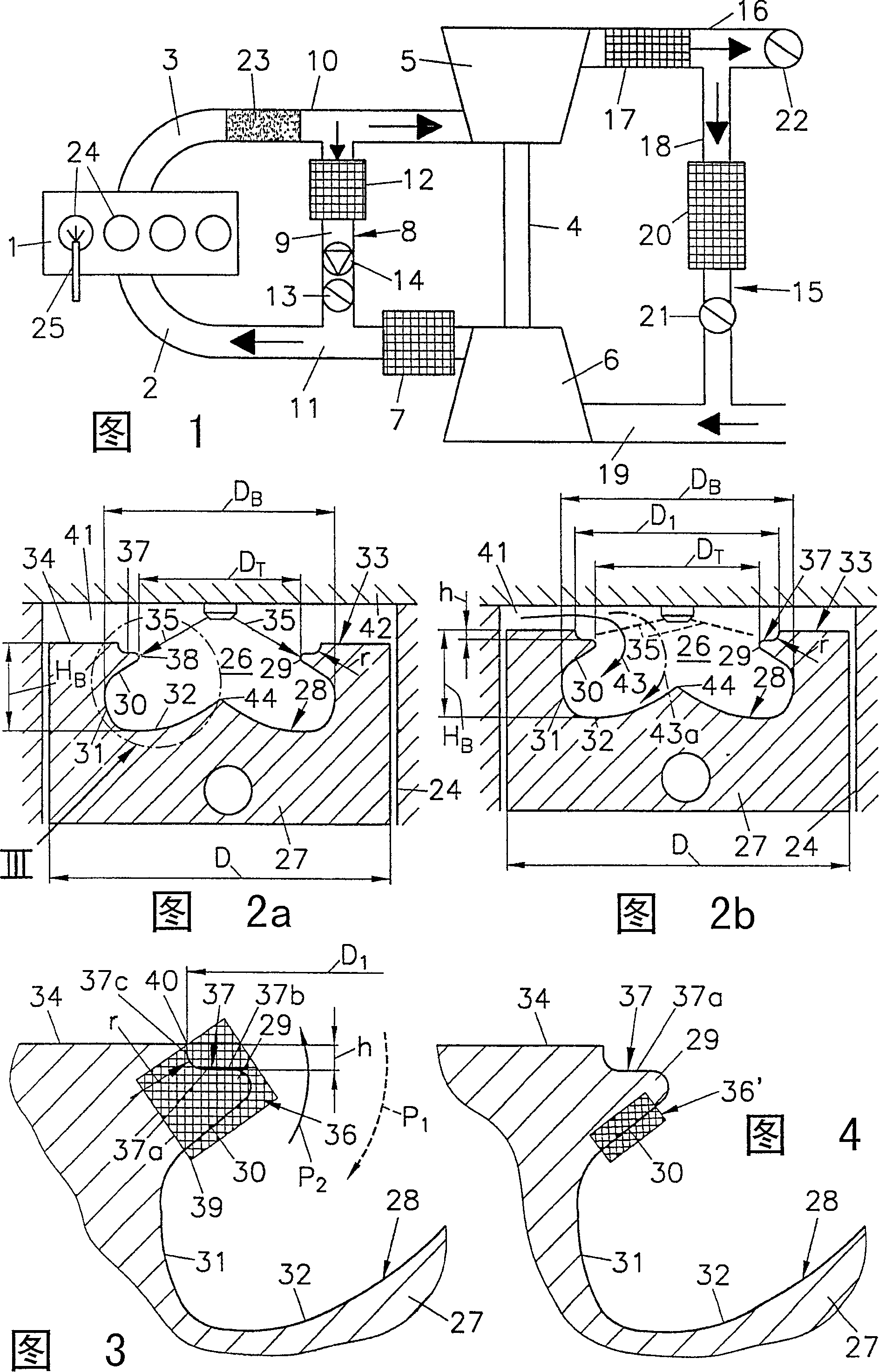

[0025] FIG. 1 shows an internal combustion engine 1 with an intake air collector 2 and an exhaust gas collector 3 . The internal combustion engine 1 is supercharged by an exhaust gas turbocharger 4 , which has an exhaust gas-driven turbine 5 and a compressor 6 driven by the turbine 5 . A charge air cooler 7 is arranged on the intake side downstream of the compressor 6 .

[0026] Furthermore, the high-pressure exhaust gas recovery system 8 has a first exhaust gas recovery line 9 between the exhaust gas line 10 and the intake line 11 . The exhaust gas recovery system 8 has an exhaust gas recovery cooler 12 and an exhaust gas recovery valve 13 . According to the pressure difference between the exhaust line 10 and the intake pipe 11, an exhaust gas pump 14 may also be provided in the first exhaust gas recovery pipe 9, so as to control or increase the exhaust gas recovery rate.

[0027] In addition to the high-pressure exhaust gas recovery system 8, there is also a low-pressure exh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com