Inclined exit type reaction tower capable of reinforcing internal cycle

An outlet type, reaction tower technology, applied in the separation of dispersed particles, chemical instruments and methods, separation methods, etc., can solve the problems of easy dust accumulation in the air outlet channel, poor internal circulation effect, and reduced internal circulation effect, etc. External circulation burden, enhanced inner circulation effect, increased residence time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

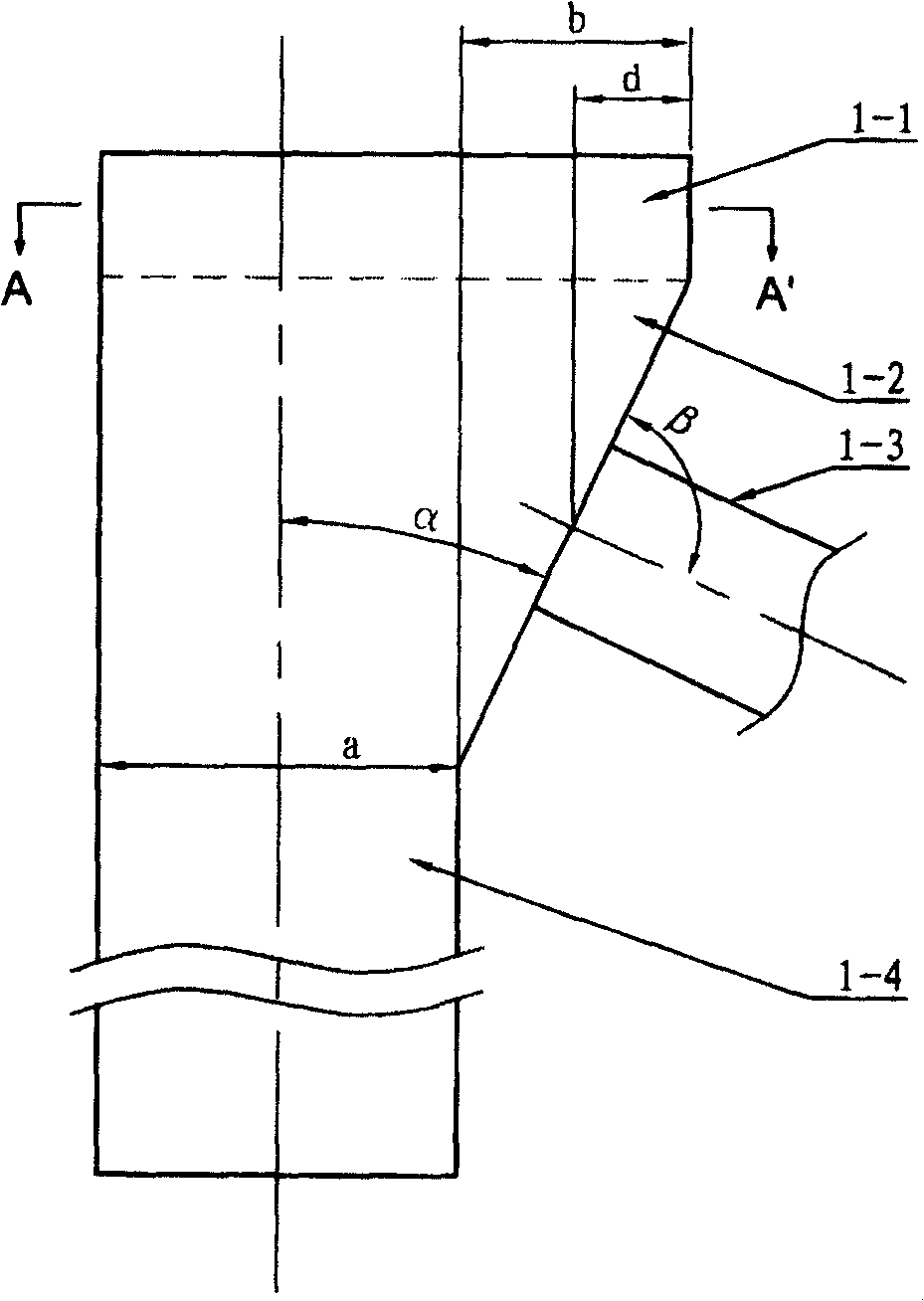

[0008] Specific implementation mode one: (see figure 1 ) The slope outlet reaction tower that can enhance the internal circulation of this embodiment includes a tower body 1-4 and an air outlet channel 1-3, and the upper part of the tower body 1-4 also includes an expansion cylinder 1-2 and an expansion extension cylinder 1 -1, the expansion cylinder 1-2 is fixedly connected to the upper part of the tower body 1-4 with an inverted trapezoidal vertical section; the expansion extension cylinder 1-1 is fixedly connected to the upper part of the expansion cylinder 1-2 The vertical upward extension part with the same shape and area as the top of the expansion cylinder 1-2; the air outlet channel 1-3 is fixedly installed on the slope of the expansion cylinder 1-2, and the air outlet channel 1- 3 communicates with the expansion cylinder 1-2, and the center line of the air outlet channel 1-3 forms an angle β with the slope.

specific Embodiment approach 2

[0009] Specific implementation mode two: (see figure 1 ) The difference between this embodiment and the first embodiment is that the vertical section of the expansion cylinder 1-2 is an inverted right-angled trapezoid, which is more conducive to the stability of the tower structure.

specific Embodiment approach 3

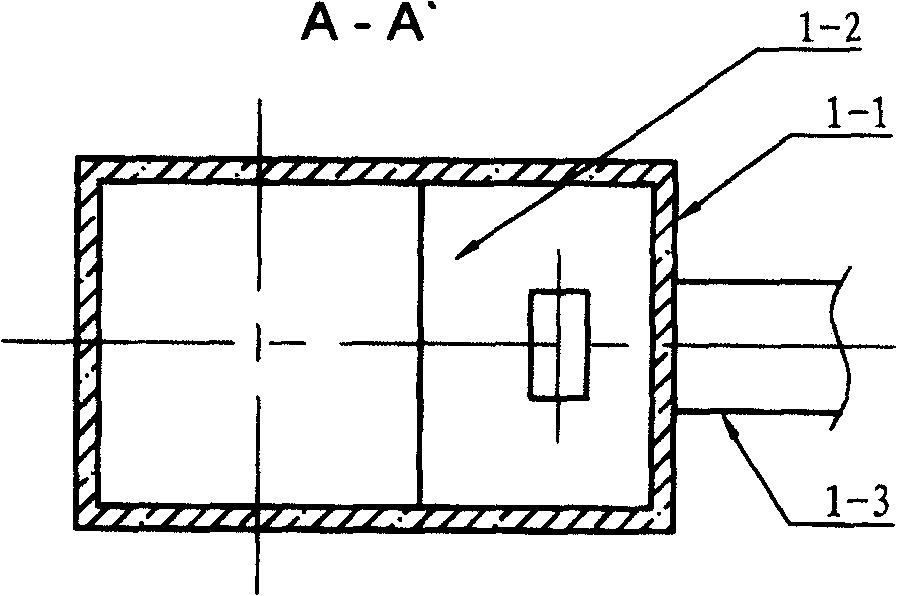

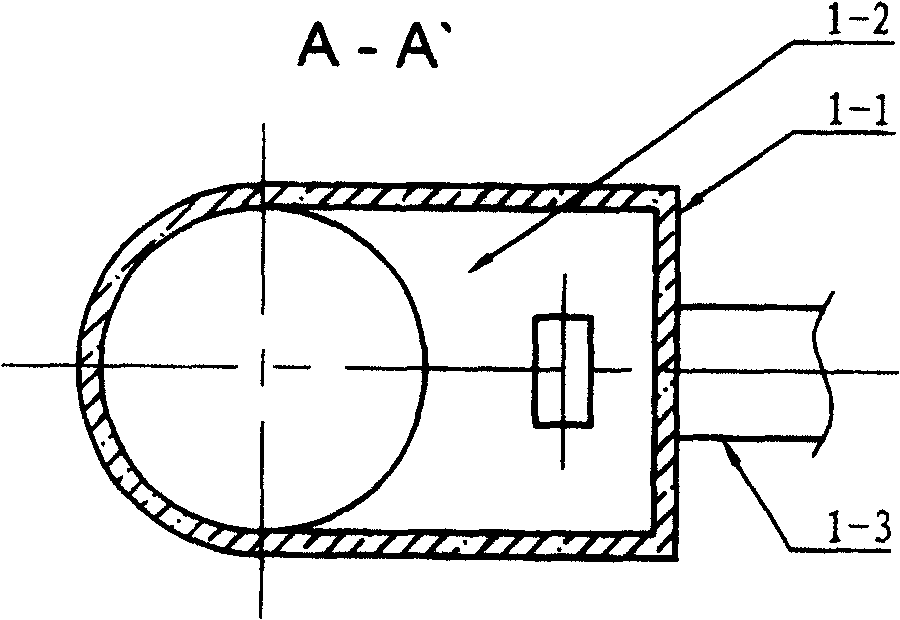

[0010] Specific implementation mode three: (see figure 1 , figure 2 ) The difference between this embodiment and the second embodiment is that the cross-sections of the bottom and the top of the expansion cylinder 1-2 are rectangular. When this embodiment is adopted, figure 1 The A-A' profile corresponding to figure 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com