Flame resisting heat insulating conditioning method for orgainic fiber fabric

A technology of organic fiber fabrics and fabrics, applied in fiber processing, textiles and papermaking, etc., can solve the problems affecting polymer fire resistance and heat insulation performance, and achieve the effect of low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

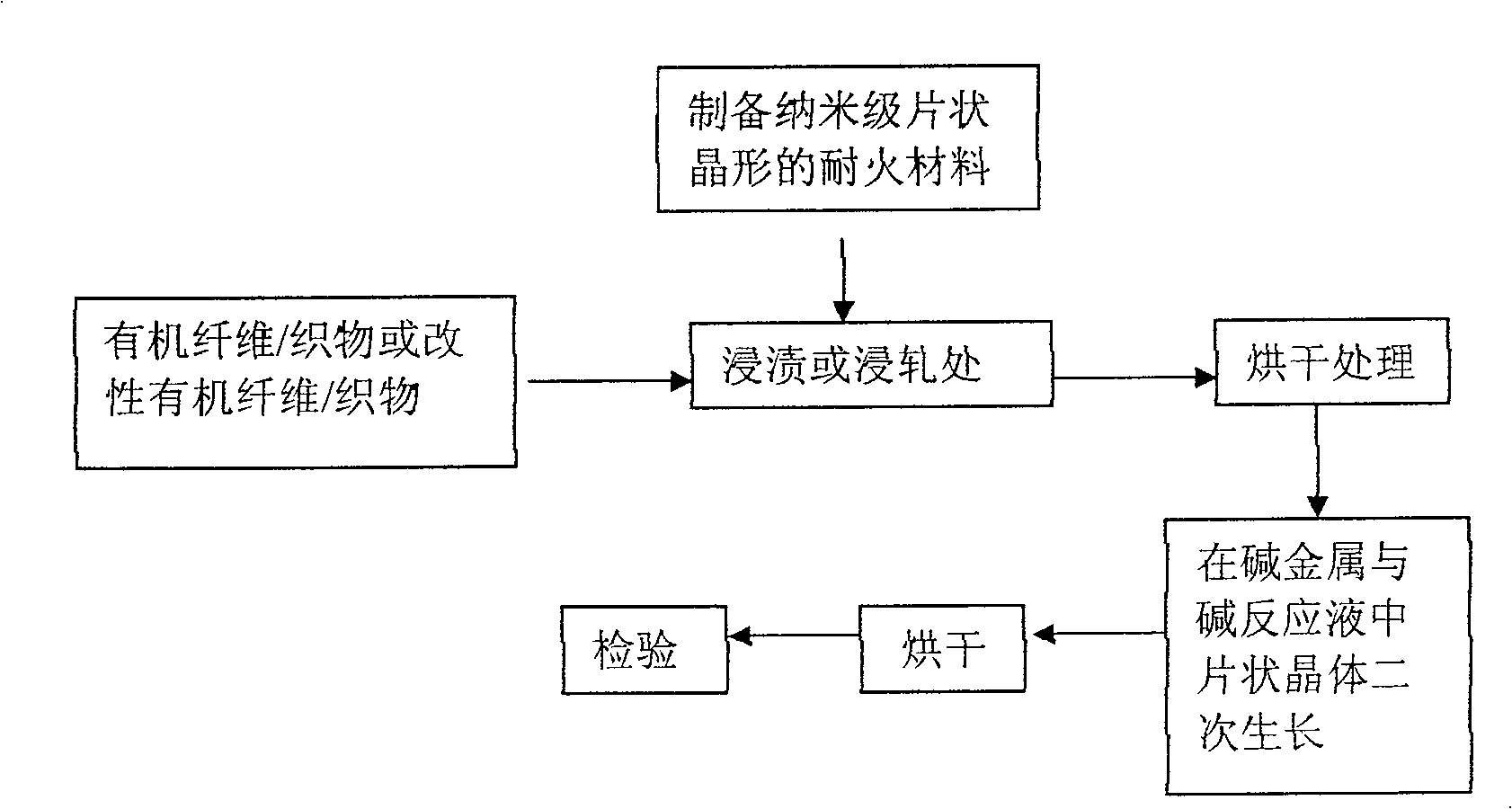

Method used

Image

Examples

Embodiment 1

[0039] 1. Preparation of magnesium hydroxide seed crystals: First, add 100ml of double-distilled water into the four-necked bottle, pass ammonia water to adjust the pH value of the system to 11, and then add ammonia water and Magnesium chloride dilute solution, the concentrations of ammonia water and magnesium chloride are: 0.2mol / L and 0.1mol / L respectively, the feeding time is 2 hours, and the constant temperature reaction is continued for 2 hours. The reaction temperature of the whole process is 40°C, and the seed crystals with a particle size of about 20nm are obtained. .

[0040] 2. Planting of magnesium hydroxide crystal seeds on cotton fabric: put 0.5g of cotton fabric into 100ml of the above-mentioned magnesium hydroxide seed crystal solution, and add ammonia water / ammonium chloride buffer solution at the same time to keep the pH value of the system at 11. The whole reaction was carried out in a constant temperature water bath at a temperature of 40°C. After 30 minute...

Embodiment 2

[0043]1. Preparation of magnesium hydroxide seed crystals: First, add 100ml of double-distilled water into the four-neck bottle, adjust the pH of the system to 11 with ammonia water, and then add ammonia water and magnesium chloride to the system at the same time at a speed of 40ml / h with a constant flow pump Dilute solution, the concentrations of ammonia water and magnesium chloride are: 0.2mol / L and 0.1mol / L respectively, the feeding time is 2 hours, and the constant temperature reaction is continued for 2 hours. The reaction temperature of the whole process is 40°C, and the seed crystals with a particle size of about 20nm are obtained.

[0044] 2. Citric acid modification of cotton fabric:

[0045] Modification solution composition: citric acid 100g / L, sodium hypophosphite 60g / L Modification process: Cotton fabric is soaked twice and rolled twice with modification solution, the excess rate is 90%-100%, pre-baked at 80°C for 5 minutes, 180°C Bake for 2 minutes, then wash wit...

Embodiment 3

[0049] 1. Preparation of aluminum hydroxide seed crystals: First, add 200ml of double-distilled water into the four-neck bottle, adjust the pH of the system to 10 with ammonia water, and then add ammonia water and chlorine to the system at a speed of 10ml / h at the same time with a constant flow pump Dilute aluminum solution, the concentrations of ammonia water and aluminum chloride are: 0.3mol / L and 0.1mol / L respectively, the feeding time is 2 hours, and the constant temperature reaction is continued for 1 hour. The reaction temperature of the whole process is 25°C, and the particle size is about 10nm. of seed crystals.

[0050] 2. Citric acid modification of cotton fabric:

[0051] Modification liquid composition: maleic acid 100g / L, sodium hypophosphite 60g / L

[0052] Modification process: Cotton fabric is dipped twice and rolled twice with the modified liquid, the excess rate is 90%-100%, pre-baked at 80°C for 5 minutes, baked at 180°C for 2 minutes, then washed with water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com