Internal anti-icing device of fanjet

A technology for turbofan engines, icing conditions, applied in the direction of engine components, machines/engines, mechanical equipment, etc., which can solve the necessary performance loss and other problems, and achieve the effect of eliminating performance degradation, reducing ice accumulation, and reducing threats

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

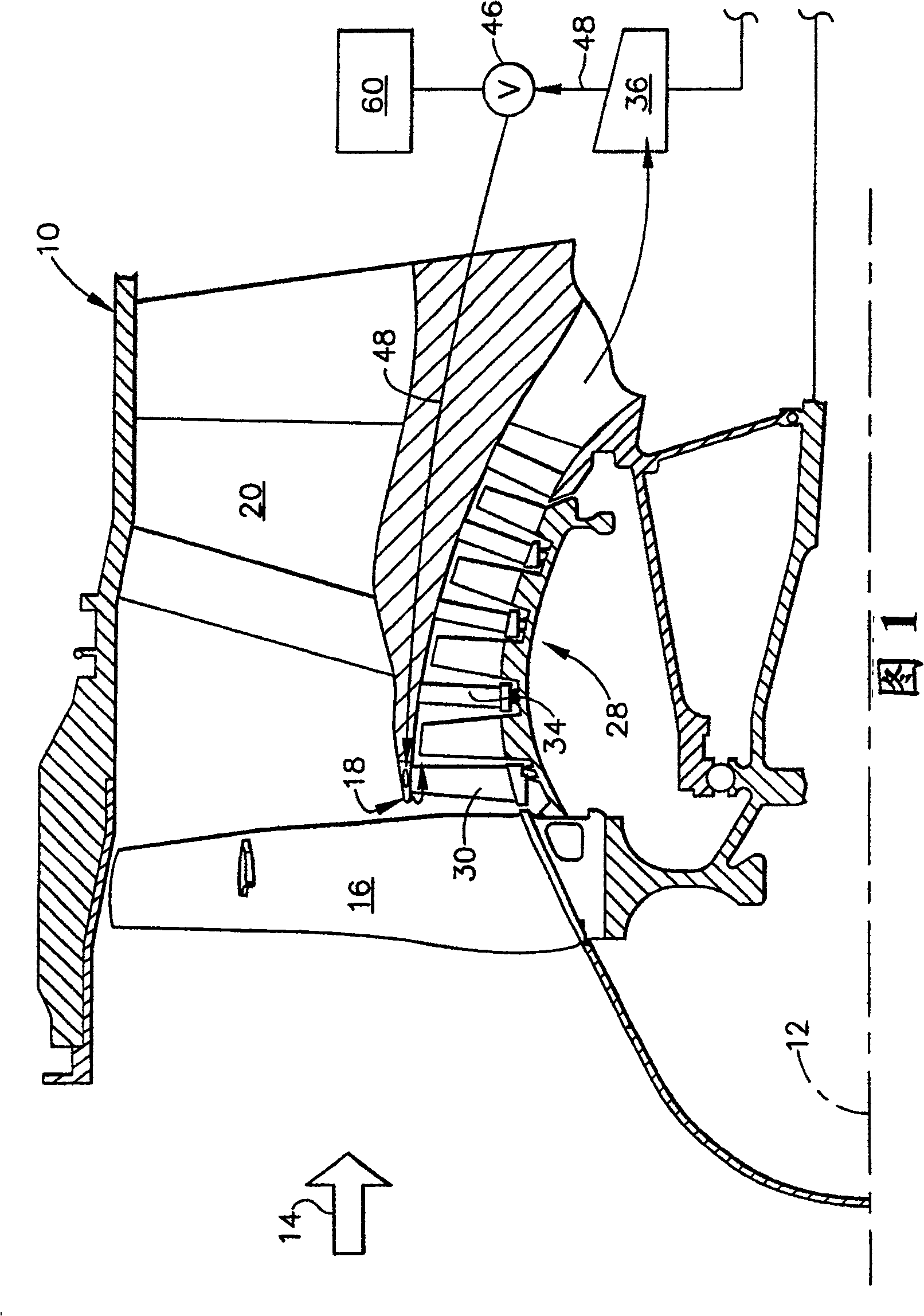

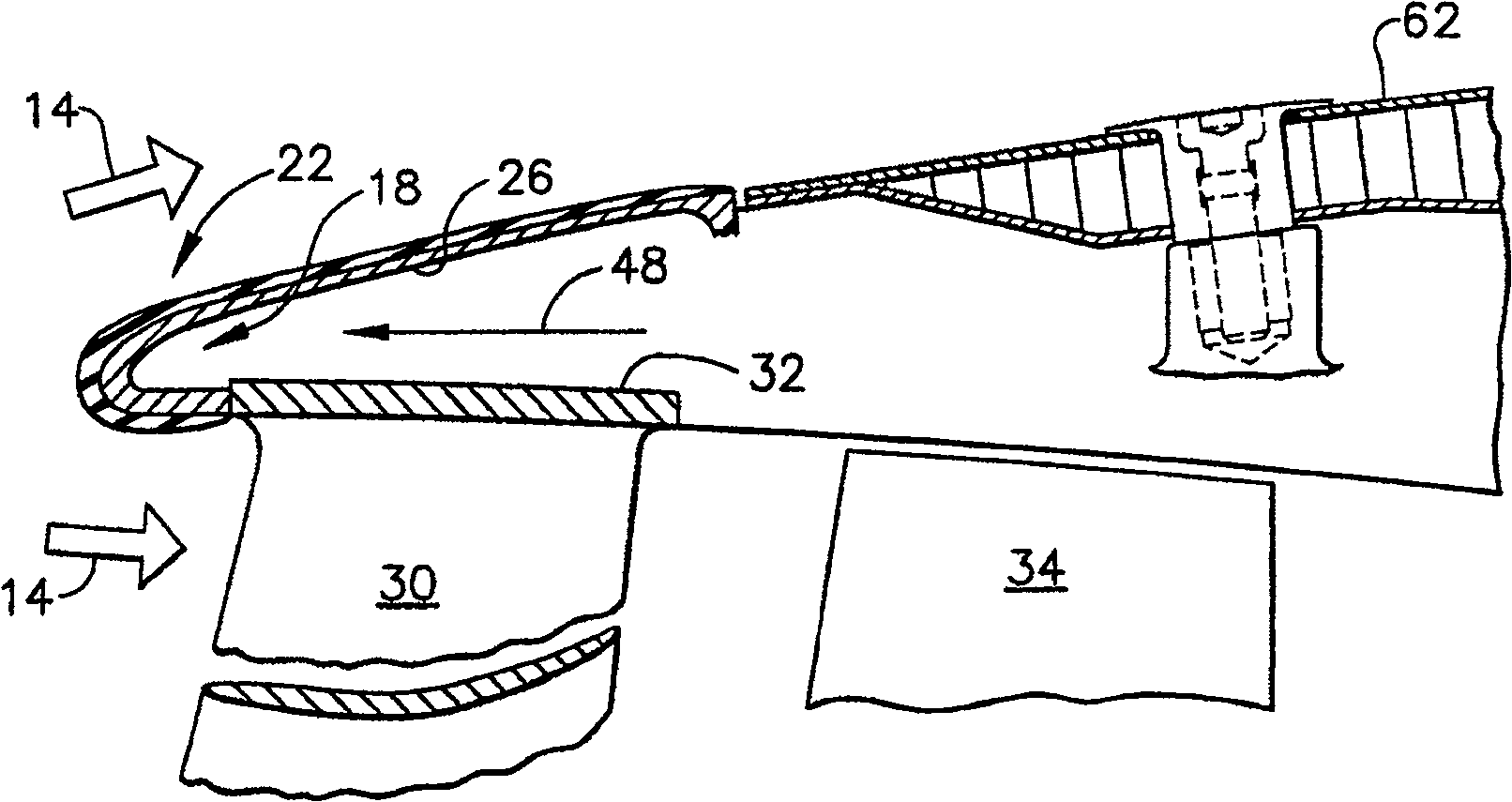

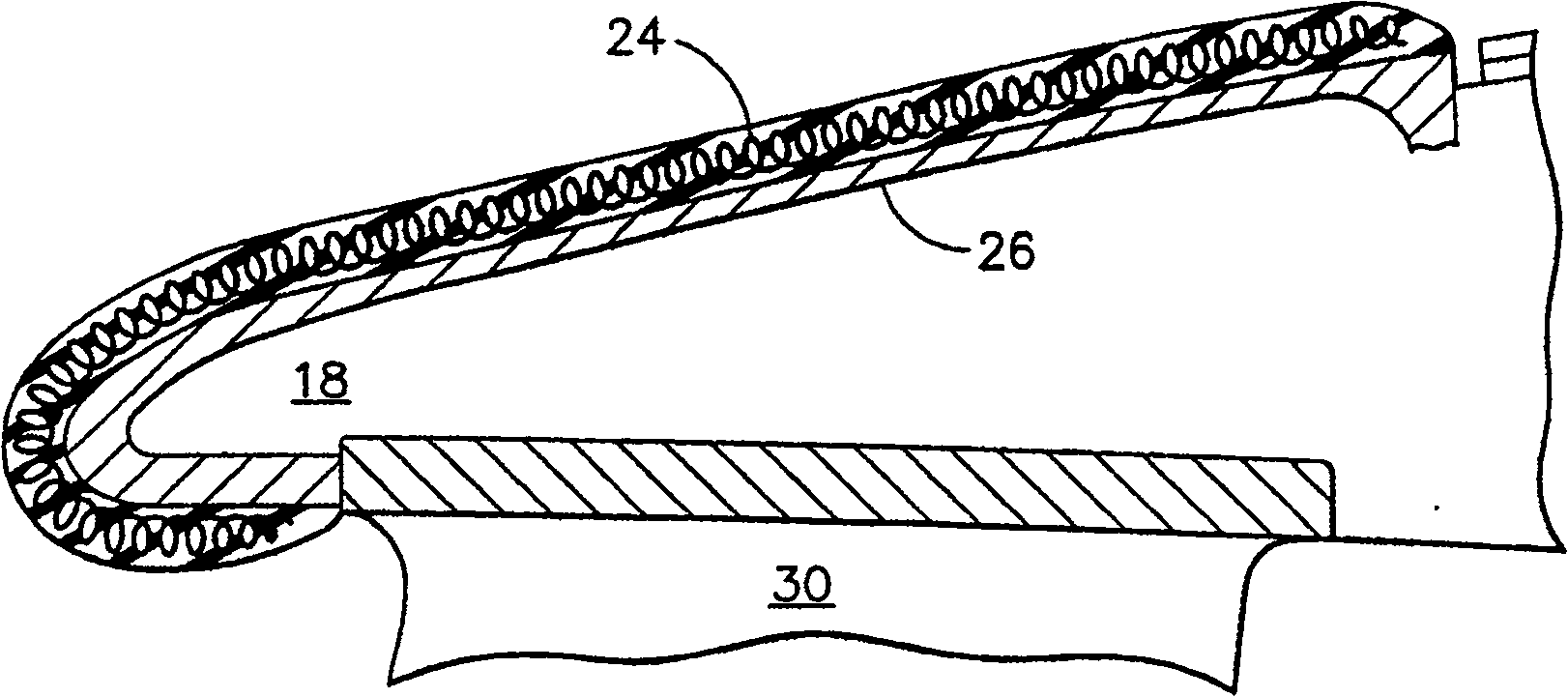

[0031] Referring to FIG. 1, there is shown a portion of a high split turbofan gas turbine engine 10 configured to operate as an aircraft (not shown) during takeoff, cruise at altitude, descent, and landing during respective flight envelope operations. shown) to provide power. The engine is axisymmetric about a longitudinal or axial center axis 12 and includes an air intake 14 at its forward end to receive ambient atmosphere 14 . Ambient atmosphere 14 first engages a row of fan rotor blades 16 . The air discharged from the fan blades is divided concentrically by the annular splitter head 18 to flow respectively through an annular bypass duct 20 surrounding the splitter and a low pressure or booster compressor 22 inside the splitter.

[0032] The basic engine configuration shown in Figure 1 is conventional and has been in commercial operation in this country for many years, although the present invention is not applied. The bypass duct 20 is surrounded by a partially shown con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com