Method for preparing biological oil through catalytic liquefaction of microalgae

A bio-oil, microalgae technology, applied in the petroleum industry, producing fat, liquid carbon-containing fuel, etc., to achieve cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

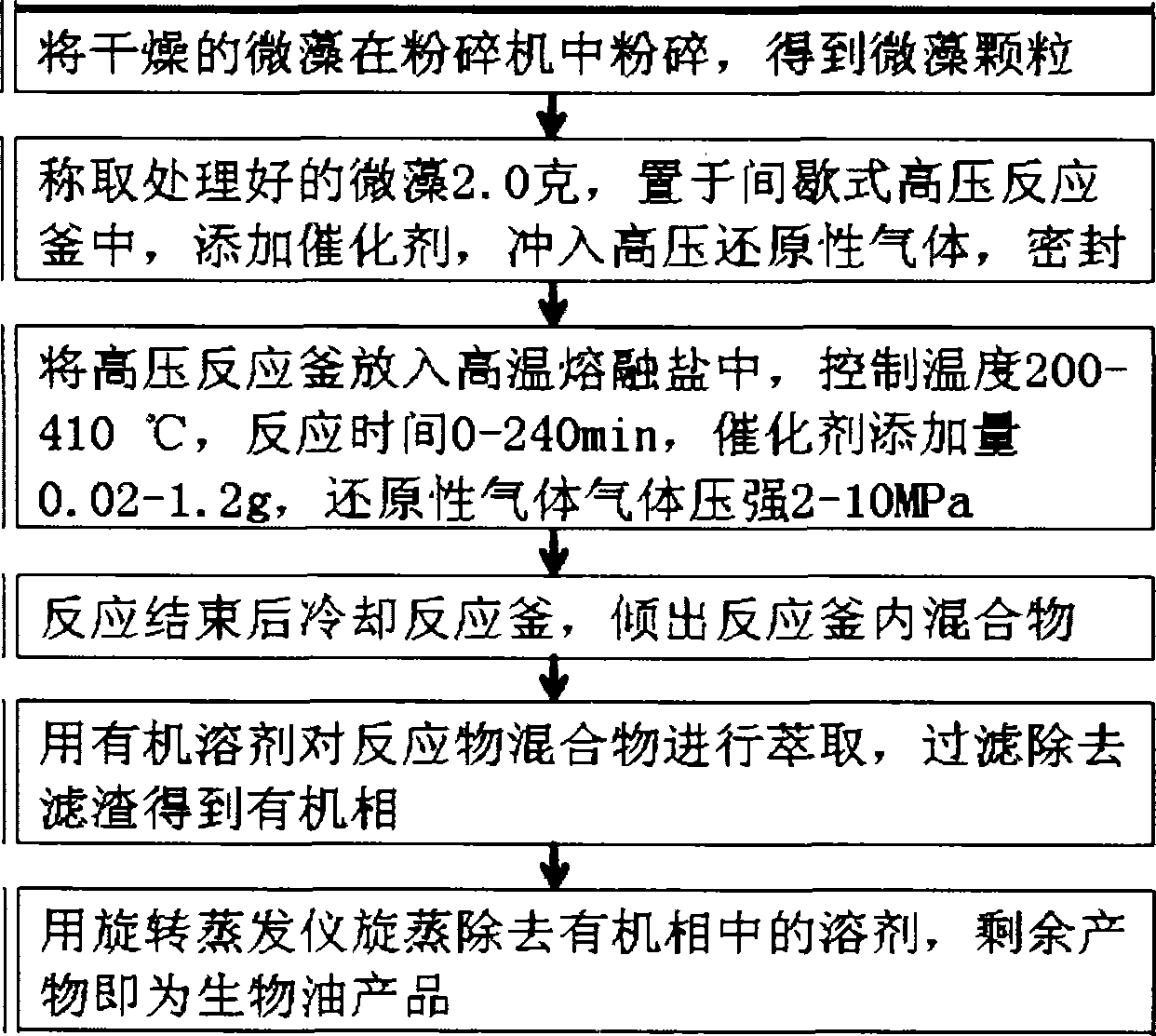

Method used

Image

Examples

Embodiment 1

[0032] The dried microalgae are pulverized in a pulverizer to obtain microalgae granules. Weigh 2.0 g of the treated microalgae, place it in a 17.2 mL batch autoclave, inject 6 MPa of hydrogen gas, and seal it. Put the autoclave into molten salt at 310°C, take out the autoclave after reacting for 20 minutes, and place it in water at room temperature for rapid cooling. After the reactor is cooled to room temperature, dry the reactor with a hair dryer, and then open the valve to depressurize the reactor. The reaction kettle was opened, the mixture in the kettle was poured out, the reaction mixture was extracted with dichloromethane, and the filter residue was removed by filtration to obtain an organic phase. The organic phase was removed by rotary evaporation with a rotary evaporator, and the remaining substance was bio-oil with a yield of 45.2wt.%.

Embodiment 2

[0034] The dried microalgae are pulverized in a pulverizer to obtain microalgae granules. Weigh 2.0 g of the treated microalgae, place it in a 17.2 mL batch autoclave, add 0.2 g of Pt / C catalyst, inject 6 MPa of hydrogen gas, and seal it. Put the autoclave into molten salt at 310°C, take out the autoclave after reacting for 20 minutes, and place it in water at room temperature for rapid cooling. After the reactor is cooled to room temperature, dry the reactor with a hair dryer, and then open the valve to depressurize the reactor. The reaction kettle was opened, the mixture in the kettle was poured out, the reaction mixture was extracted with dichloromethane, and the filter residue was removed by filtration to obtain an organic phase. The organic phase was removed by rotary evaporation with a rotary evaporator, and the remaining substance was bio-oil with a yield of 46.17wt.%.

Embodiment 3

[0036] The dried microalgae are pulverized in a pulverizer to obtain microalgae granules. Weigh 2.0 g of the treated microalgae, place it in a 17.2 mL batch autoclave, add 0.2 g of Pd / C catalyst, inject 6 MPa of hydrogen gas, and seal it. Put the autoclave into molten salt at 310°C, take out the autoclave after reacting for 20 minutes, and place it in water at room temperature for rapid cooling. After the reactor is cooled to room temperature, dry the reactor with a hair dryer, and then open the valve to depressurize the reactor. The reaction kettle was opened, the mixture in the kettle was poured out, the reaction mixture was extracted with dichloromethane, and the filter residue was removed by filtration to obtain an organic phase. The organic phase was removed by rotary evaporation with a rotary evaporator, and the remaining substance was bio-oil with a yield of 45.55wt.%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com